Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT REAR WIPER MOTOR AND BRACKET ASSEMBLY

(a) Check the wiper low operation.

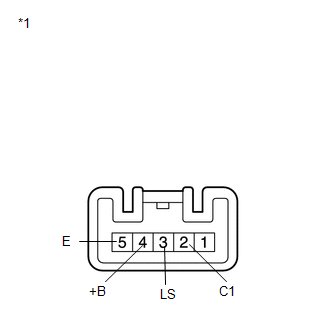

(1) Connect a battery positive (+) lead to terminal 4 (+B), and a negative (-) lead to terminal 3 (LS) and terminal 5 (E), and check that the motor operates.

OK:

Motor operates.

If the result is not as specified, replace the motor assembly.

(b) Check the intermittent operation.

(1) Connect a battery positive (+) lead to terminal 4 (+B), and a negative (-) lead to terminal 2 (C1) and terminal 5 (E), and check that the motor operates.

OK:

Motor operates.

If the result is not as specified, replace the rear wiper motor and bracket assembly.

Text in Illustration|

*1 |

Component without harness connected (Rear Wiper Motor and Bracket Assembly) |

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE BACK DOOR PANEL TRIM ASSEMBLY

2. REMOVE REAR WIPER ARM HEAD CAP

(a) Disengage the 4 claws and remove the rear wiper arm head cap as shown

in the illus ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL REAR WIPER MOTOR AND BRACKET ASSEMBLY

(a) Install the rear wiper motor and bracket assembly with the 3 bolts.

Torque:

5.5 N·m {56 kgf·cm, 49 in ...

Other materials about Toyota Venza:

Lost Communication with Gateway Module (Power Management2) (U1002)

DESCRIPTION

The power management control ECU will store this DTC when no signals

can be received from the ECUs that have been memorized as those that are

connected to the power management bus.

When the power management control ECU receives ...

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

Use the following procedure to troubleshoot the audio and visual system.

*: Use the Techstream.

PROCEDURE

1.

VEHICLE BROUGHT TO WORKSHOP

NEXT

...

On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

CAUTION:

Be sure to follow the correct removal and installation procedures of the door

side airbag sensor.

PROCEDURE

1. INSPECT DOOR SIDE AIRBAG SENSOR (VEHICLE NOT INVOLVED IN COLLISION)

(a) Perform a diag ...

0.1619