Toyota Venza: Installation

INSTALLATION

PROCEDURE

1. INSTALL REAR WIPER MOTOR AND BRACKET ASSEMBLY

|

(a) Install the rear wiper motor and bracket assembly with the 3 bolts. Torque: 5.5 N·m {56 kgf·cm, 49 in·lbf} |

|

(b) Connect the connector.

2. INSTALL REAR WIPER MOTOR GROMMET

|

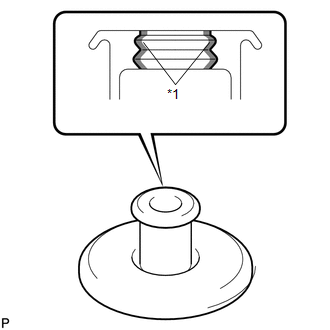

(a) Apply MP grease to the entire surface of the wiper motor grommet lip. Text in Illustration

HINT: Make sure that the hole does not get clogged with grease and the grooves on the lip are filled with grease. |

|

|

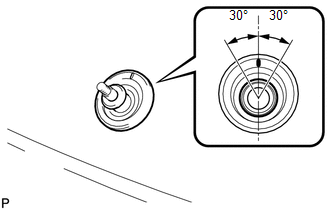

(b) Install the rear wiper motor grommet with the position mark facing upward as shown in the illustration. |

|

3. INSTALL REAR WIPER ARM AND BLADE ASSEMBLY

(a) Stop the wiper motor at the automatic stop position.

(b) When reusing the rear wiper arm and blade assembly:

|

(1) Clean the wiper arm serrations. Text in Illustration

|

|

(c) When reusing the rear wiper motor and bracket assembly:

|

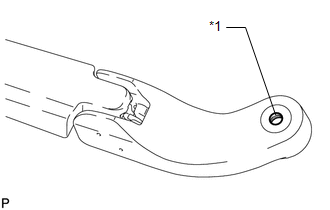

(1) Clean the wiper pivot serrations with a wire brush. Text in Illustration

|

|

|

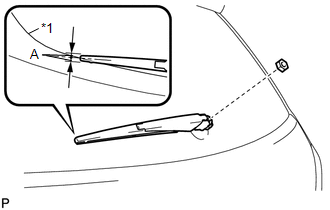

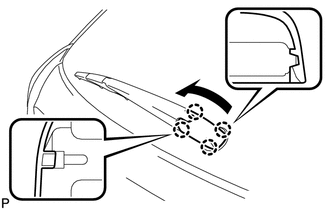

(d) Install the rear wiper arm and blade assembly with the nut to the position shown in the illustration. Standard Measurement

Torque: 5.5 N·m {56 kgf·cm, 49 in·lbf} |

|

(e) Operate the rear wiper while spraying washer fluid onto the back door glass. Make sure that the rear wiper functions properly and the wiper does not come into contact with the vehicle body.

4. INSTALL REAR WIPER ARM HEAD CAP

|

(a) Engage the 4 claws to install the cap as shown in the illustration. |

|

5. INSTALL BACK DOOR PANEL TRIM ASSEMBLY

.gif)

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT REAR WIPER MOTOR AND BRACKET ASSEMBLY

(a) Check the wiper low operation.

(1) Connect a battery positive (+) lead to terminal 4 (+B), and a negative (-)

lead to ...

Rear Wiper Rubber

Rear Wiper Rubber

Components

COMPONENTS

ILLUSTRATION

Replacement

REPLACEMENT

PROCEDURE

1. REMOVE REAR WIPER BLADE

(a) Disconnect the rear wiper arm head cap.

...

Other materials about Toyota Venza:

Front Passenger Side Power Mirror cannot be Adjusted with Power Mirror Switch

SYSTEM DESCRIPTION

When the mirror adjust switch is operated, the main body ECU (driver side junction

block assembly) detects the switch operation and sends the mirror adjust switch

signal to the outer mirror control ECU assembly (front passenger door) vi ...

Differential System

Precaution

PRECAUTION

Before disassembly, clean the outside of the differential assembly and

remove any sand or mud to prevent it from entering the inside of the assembly

during disassembly and installation.

When removing an installed pa ...

Occupant Classification System Malfunction (B1650/32)

DESCRIPTION

The occupant classification system circuit consists of the center airbag sensor

assembly and occupant classification system.

If the center airbag sensor assembly receives signals from the occupant classification

ECU, it determines whether the ...

0.1613

.png)