Toyota Venza: Front Power Seat does not Operate with Front Power Seat Switch

DESCRIPTION

Signals are input into the position control ECU and switch assembly. The built-in ECU manages the signals received from the position control ECU and switch assembly, and operates each motor. If the position control ECU and switch assembly receives more than 2 motor operation signals, the motor is stopped. Manual operation is restarted after the position control ECU and switch assembly receives 1 signal only.

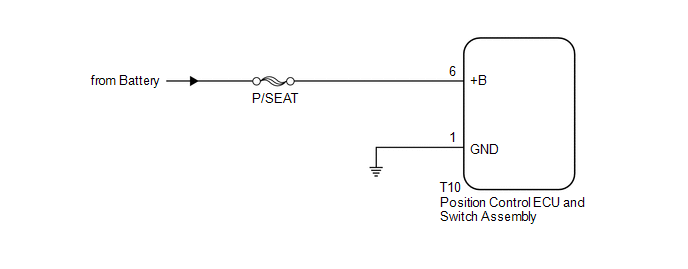

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

CHECK FRONT POWER SEAT OPERATION |

(a) Check that each function of the power seat operates normally by using the

position control ECU and switch assembly (See page

.gif) ).

).

|

Result |

Proceed to |

|---|---|

|

All power seat functions do not operate |

A |

|

One or more power seat functions do not operate |

B |

| B | .gif) |

GO TO OTHER DIAGNOSIS PROCEDURE (One or more Power Seat Motors do not Operate) |

|

|

2. |

CHECK HARNESS AND CONNECTOR (POSITION CONTROL ECU AND SWITCH ASSEMBLY - BATTERY) |

(a) Disconnect the T10 position control ECU and switch assembly connectors.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

T10-6 (+B) - Body ground |

Always |

11 to 14 V |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

CHECK HARNESS AND CONNECTOR (POSITION CONTROL ECU AND SWITCH ASSEMBLY - BODY GROUND) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

T10-1 (GND) - Body ground |

Always |

Below 1 Ω |

| OK | .gif) |

REPLACE POSITION CONTROL ECU AND SWITCH ASSEMBLY |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Short in Sensor with Motor Power Supply Circuit (B2658)

Short in Sensor with Motor Power Supply Circuit (B2658)

DESCRIPTION

This DTC is stored if sensor voltage does not reach the designated voltage while

the slide motor is operating.

DTC Code

DTC Detection Condition

Trouble ...

One or more Power Seat Motors do not Operate

One or more Power Seat Motors do not Operate

DESCRIPTION

Signals are input into the position control ECU and switch assembly. The built-in

ECU manages the signals received from the position control ECU and switch assembly,

and operates each ...

Other materials about Toyota Venza:

Readiness Monitor Drive Pattern

READINESS MONITOR DRIVE PATTERN

1. PURPOSE OF READINESS TESTS

The On-Board Diagnostic (OBD II) system is designed to monitor the performance

of emission related components, and indicate any detected abnormalities

using DTCs (Diagnostic Trouble ...

On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

CAUTION:

Be sure to follow the correct removal and installation procedures of the driver

side knee airbag assembly.

PROCEDURE

1. INSPECT DRIVER SIDE KNEE AIRBAG ASSEMBLY (VEHICLE NOT INVOLVED IN COLLISION)

...

Fog light switch

The fog lights improve visibility in difficult driving conditions, such as

in rain or fog. The fog lights can be used when the headlights are on low beam.

Type A

1. Off

2. On

Type B

1. Off

2. On

Wiper intervals can be adjusted for intermittent ...

0.1228

.gif)