Toyota Venza: Horn

Components

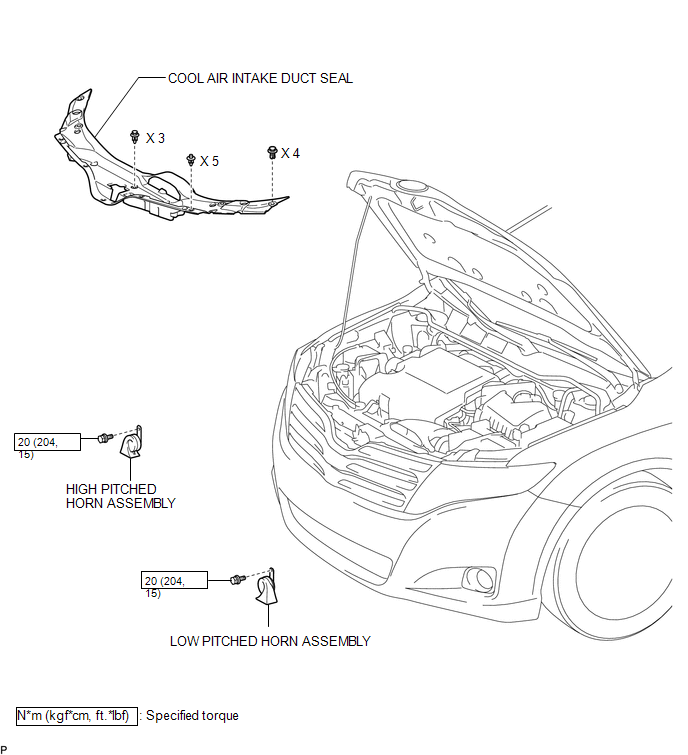

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

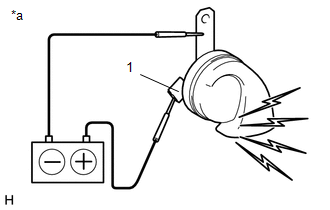

1. INSPECT LOW PITCHED HORN ASSEMBLY

|

(a) Apply battery voltage and check the operation of the low pitched horn assembly according to the table below. OK:

If the result is not as specified, replace the low pitched horn assembly. |

|

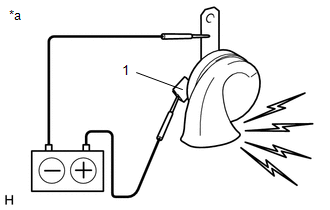

2. INSPECT HIGH PITCHED HORN ASSEMBLY

|

(a) Apply battery voltage and check the operation of the high pitched horn assembly according to the table below. OK:

If the result is not as specified, replace the high pitched horn assembly. |

|

Removal

REMOVAL

PROCEDURE

1. REMOVE COOL AIR INTAKE DUCT SEAL

.gif)

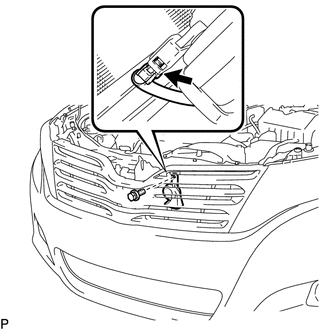

2. REMOVE LOW PITCHED HORN ASSEMBLY

|

(a) Disconnect the connector. |

|

(b) Remove the bolt and low pitched horn assembly.

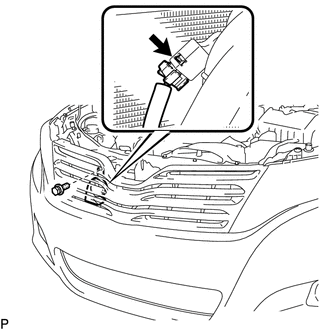

3. REMOVE HIGH PITCHED HORN ASSEMBLY

|

(a) Disconnect the connector. |

|

(b) Remove the bolt and high pitched horn assembly.

Installation

INSTALLATION

PROCEDURE

1. INSTALL LOW PITCHED HORN ASSEMBLY

(a) Install the low pitched horn assembly with the bolt.

Torque:

20 N·m {204 kgf·cm, 15 ft·lbf}

(b) Connect the connector.

2. INSTALL HIGH PITCHED HORN ASSEMBLY

(a) Install the high pitched horn assembly with the bolt.

Torque:

20 N·m {204 kgf·cm, 15 ft·lbf}

(b) Connect the connector.

3. INSTALL COOL AIR INTAKE DUCT SEAL

.gif)

Horn

Horn

...

Horn System

Horn System

Precaution

PRECAUTION

NOTICE:

When disconnecting the cable from the negative (-) battery terminal, initialize

the following system after the cable is reconnected.

System Name

...

Other materials about Toyota Venza:

Accelerator Pedal

Components

COMPONENTS

ILLUSTRATION

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT ACCELERATOR PEDAL SENSOR ASSEMBLY

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) En ...

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE TRANSFER AND TRANSAXLE SETTING STUD BOLT

(a) Remove the 4 transfer and transaxle setting stud bolts.

2. REMOVE NO. 2 TRANSFER CASE PLUG

(a) Remove the No. ...

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE HOOD TO RADIATOR SUPPORT SEAL

(a) Using a clip remover, disengage the 10 clips and remove the hood

to radiator support seal.

2. REMOVE HOOD INSULATOR

...

0.1446