Toyota Venza: Short in Sensor with Motor Power Supply Circuit (B2658)

DESCRIPTION

This DTC is stored if sensor voltage does not reach the designated voltage while the slide motor is operating.

|

DTC Code |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

B2658 |

Malfunction in supply voltage for the seat slide control position sensor |

|

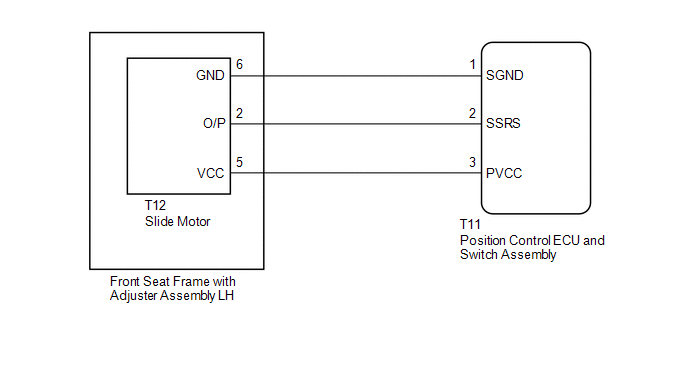

WIRING DIAGRAM

PROCEDURE

|

1. |

CHECK FOR DTC |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Driver Seat / Trouble Codes.

(e) Clear the DTC (See page .gif) ).

).

(f) Recheck for DTC B2658.

|

Result |

Proceed to |

|---|---|

|

DTC B2658 is output |

A |

|

DTC B2658 is not output |

B |

| B | .gif) |

USE SIMULATION METHOD TO CHECK |

|

|

2. |

CHECK HARNESS AND CONNECTOR (POSITION CONTROL ECU AND SWITCH ASSEMBLY - SLIDE MOTOR) |

(a) Disconnect the T11 the position control ECU and switch assembly connector.

(b) Disconnect the T12 the slide motor (front seat frame with adjuster assembly LH).

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

T11-3 (PVCC) - T12-5 (VCC) |

Always |

Below 1 Ω |

|

T11-2 (SSRS) - T12-2 (O/P) |

Always |

Below 1 Ω |

|

T11-1 (SGND) - T12-6 (GND) |

Always |

Below 1 Ω |

|

T11-3 (PVCC) - Body ground |

Always |

10 kΩ or higher |

|

T11-2 (SSRS) - Body ground |

Always |

10 kΩ or higher |

|

T11-1 (SGND) - Body ground |

Always |

10 kΩ or higher |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

CHECK POSITION CONTROL ECU AND SWITCH ASSEMBLY |

(a) Reconnect the T11 the position control ECU and switch assembly connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

T11-1 (SGND) - T11-3 (PVCC) |

Slide switch on |

5.5 to 6.5 V |

| OK | .gif) |

REPLACE FRONT SEAT FRAME WITH ADJUSTER ASSEMBLY LH |

| NG | .gif) |

REPLACE POSITION CONTROL ECU AND SWITCH ASSEMBLY |

Slide Sensor Malfunction (B2650)

Slide Sensor Malfunction (B2650)

DESCRIPTION

When the position control ECU and switch assembly does not receive a sensor signal

despite forward or backward movement of seat by power seat motor operation, this

DTC is output.

...

Front Power Seat does not Operate with Front Power Seat Switch

Front Power Seat does not Operate with Front Power Seat Switch

DESCRIPTION

Signals are input into the position control ECU and switch assembly. The built-in

ECU manages the signals received from the position control ECU and switch assembly,

and operates each ...

Other materials about Toyota Venza:

Electrical Key Oscillator(for Front Floor)

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL ELECTRICAL KEY OSCILLATOR

(a) Engage the clamp and install the electrical key oscillator.

NOTICE:

Be careful when installing the electrical key osci ...

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" ...

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

Use the following procedure listed to troubleshoot the Active Torque

Control 4WD system.

*: Use the Techstream.

PROCEDURE

1.

VEHICLE BROUGHT TO WORKSHOP

...

0.1146

.gif)