Toyota Venza: Diagnosis Circuit

DESCRIPTION

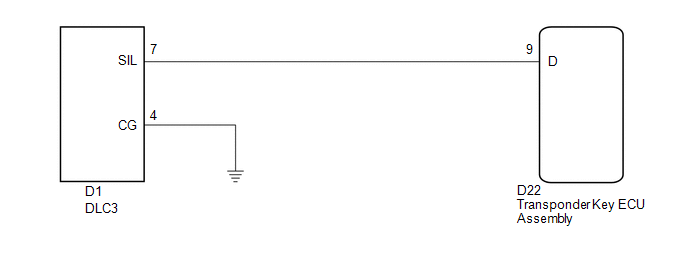

This circuit is used to read the DTCs that are output from the transponder key ECU assembly with the Techstream.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

If the transponder key ECU assembly is replaced, register the key and ECU communication

ID (See page .gif) ).

).

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (DLC3 - TRANSPONDER KEY ECU AND BODY GROUND) |

|

(a) Disconnect the transponder key ECU assembly connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D22-9 (D) - D1-7 (SIL) |

Always |

Below 1 Ω |

|

D1-4 (CG) - Body ground |

Always |

Below 1 Ω |

|

D22-9 (D) - Body ground |

Always |

10 kΩ or higher |

|

D1-7 (SIL)- Body ground |

Always |

10 kΩ or higher |

|

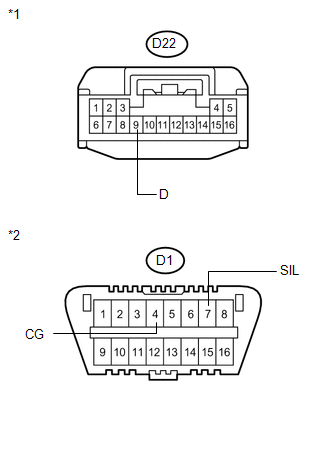

*1 |

Front view of wire harness connector (to Transponder Key ECU Assembly) |

|

*2 |

Front view of wire harness connector (to DLC3) |

| OK | .gif) |

REPLACE TRANSPONDER KEY ECU ASSEMBLY |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

ECU Power Source Circuit

ECU Power Source Circuit

DESCRIPTION

This circuit provides power to operate the transponder key ECU assembly.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

If the transponder key ECU assembly is replaced, register the ...

Other materials about Toyota Venza:

Short in Passenger Side Airbag Variable Vent Hole Squib Circuit (B181A/7A-B181D/7A)

DESCRIPTION

The passenger side airbag variable vent hole squib circuit consists of the center

airbag sensor assembly and front passenger airbag assembly.

The center airbag sensor assembly uses this circuit to deploy the airbag when

deployment conditions ...

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

HINT:

If a trouble code is stored during the DTC check, inspect the trouble areas listed

for that code. For details of the code, refer to "See page" below.

1. TRANSPONDER KEY ECU DIAGNOSTIC TROUBLE CODE CHART

Trans ...

Purge Valve

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT NO. 1 VACUUM SWITCHING VALVE ASSEMBLY

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Te ...

0.1442