Toyota Venza: Blower Motor Circuit

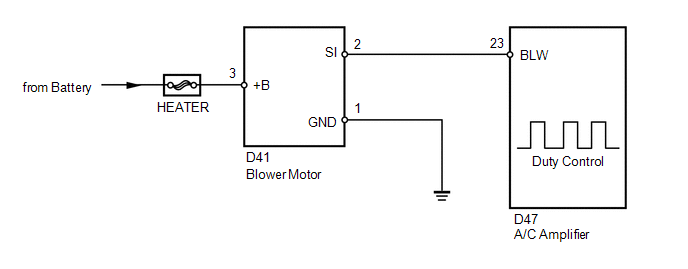

DESCRIPTION

The blower motor is operated by signals from the A/C amplifier. Blower motor speed signals are transmitted in accordance with changes in the duty ratio.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body / Air Conditioner / Active Test.

(e) Check the operation by referring to the table below.

Air Conditioner|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Blower Motor |

Blower motor |

Min.: 0, Max.: 31 |

- |

OK:

Blower motor operates and blower motor speed level changes.

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (Blower motor does not operate) |

B |

|

NG (Blower motor operates but does not change speed) |

C |

| A | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| C | .gif) |

GO TO STEP 6 |

|

|

2. |

CHECK HARNESS AND CONNECTOR (BLOWER MOTOR - BODY GROUND) |

|

(a) Disconnect the blower motor connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

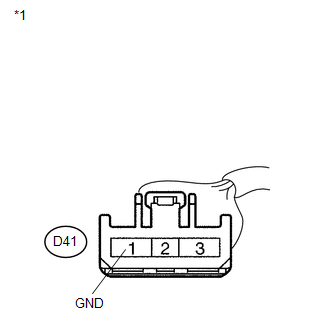

D41-1 (GND) - Body ground |

Always |

Below 1 Ω |

|

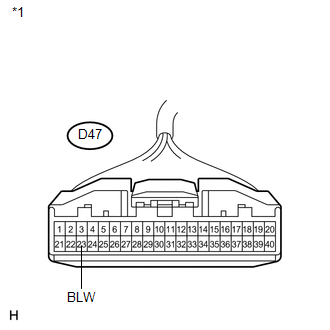

*1 |

Front view of wire harness connector (to Blower Motor) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

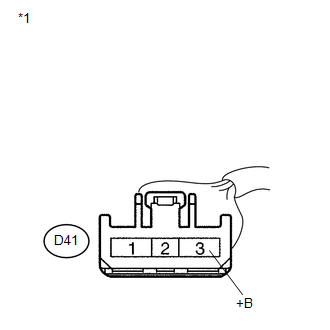

CHECK HARNESS AND CONNECTOR (BLOWER MOTOR - BATTERY) |

|

(a) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

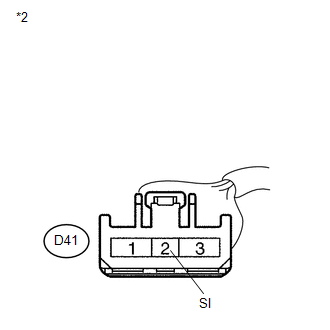

CHECK HARNESS AND CONNECTOR (BLOWER MOTOR - A/C AMPLIFIER) |

|

(a) Disconnect the A/C amplifier connector. |

|

|

(b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

INSPECT BLOWER MOTOR |

(a) Reconnect the blower motor connector.

|

(b) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| NG | .gif) |

REPLACE BLOWER MOTOR |

|

|

6. |

INSPECT A/C AMPLIFIER |

|

(a) Remove the A/C amplifier. |

|

(b) Reconnect the A/C amplifier connector.

(c) Turn the ignition switch to ON.

(d) Turn the blower switch LO.

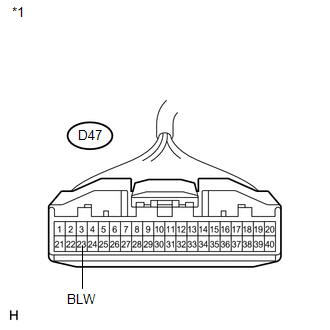

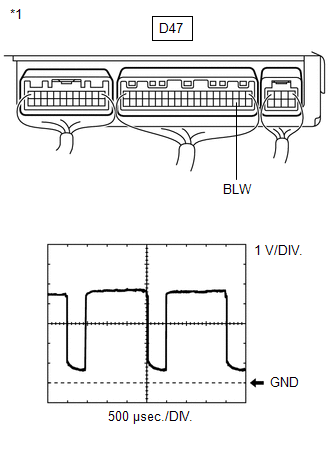

(e) Measure the waveform between terminal D47-23 (BLW) of the A/C amplifier and body ground.

|

Item |

Content |

|---|---|

|

Tool setting |

1 V/DIV., 500 μs/DIV. |

|

Vehicle condition |

Ignition switch ON Blower switch LO |

OK:

Waveform is as shown in the illustration.

HINT:

The waveform varies with the blower speed.

Text in Illustration|

*1 |

Component with harness connected (A/C Amplifier) |

| OK | .gif) |

REPLACE BLOWER MOTOR |

| NG | .gif) |

REPLACE A/C AMPLIFIER |

Air Conditioning Compressor Magnetic Clutch Circuit

Air Conditioning Compressor Magnetic Clutch Circuit

DESCRIPTION

When the A/C amplifier is turned on, a magnetic clutch ON signal is sent from

the MGC terminal of the A/C amplifier. Then, the MGC relay turns on to operate the

magnetic clutch.

WIRI ...

IG Power Source Circuit

IG Power Source Circuit

DESCRIPTION

The main power source is supplied to the A/C amplifier when the ignition switch

is ON.

The power source is used for operating the A/C amplifier and servo motor, etc.

WIRING DIAGRAM

...

Other materials about Toyota Venza:

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the LH side and RH side.

The following procedure is for the LH side.

If the sensor rotor needs to be replaced, replace it together with the

rear drive shaft assembly. ...

Washer Nozzle(for Front Side)

Components

COMPONENTS

ILLUSTRATION

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT FRONT WASHER NOZZLE SUB-ASSEMBLY

(a) With the engine running, check that the center stream of washer fluid sprays

on the windshield within the ar ...

Front Airbag Sensor LH Malfunction (B1615/14)

DESCRIPTION

The front airbag sensor LH circuit consists of the center airbag sensor assembly

and front airbag sensor LH.

The front airbag sensor LH detects impacts to the vehicle and sends signals to

the center airbag sensor assembly to determine if the ...

0.16

.gif)