Toyota Venza: IG Power Source Circuit

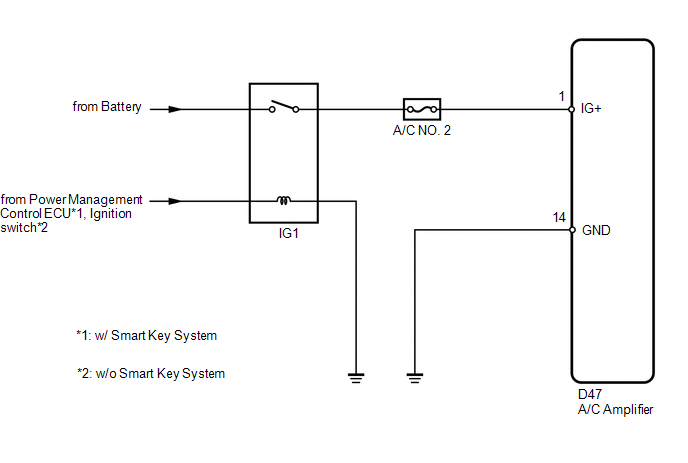

DESCRIPTION

The main power source is supplied to the A/C amplifier when the ignition switch is ON.

The power source is used for operating the A/C amplifier and servo motor, etc.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

HINT:

Start the engine before inspection. Check the IG1 relay or battery if the engine does not start.

PROCEDURE

|

1. |

INSPECT A/C AMPLIFIER |

|

(a) Remove the A/C amplifier with its connectors still connected. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D47-1 (IG+) - D47-14 (GND) |

Ignition switch off |

Below 1 V |

|

D47-1 (IG+) - D47-14 (GND) |

Ignition switch ON |

11 to 14 V |

|

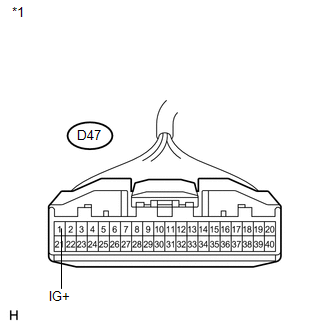

*1 |

Component with harness connected (A/C Amplifier) |

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

|

|

2. |

CHECK HARNESS AND CONNECTOR (A/C AMPLIFIER - BATTERY) |

|

(a) Disconnect the A/C amplifier connector. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D47-1 (IG+) - Body ground |

Ignition switch off |

Below 1 V |

|

D47-1 (IG+) - Body ground |

Ignition switch ON |

11 to 14 V |

|

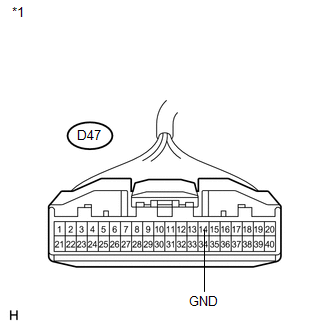

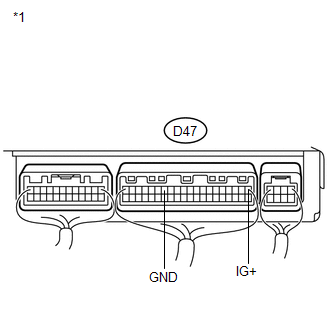

*1 |

Front view of wire harness connector (to A/C Amplifier) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

CHECK HARNESS AND CONNECTOR (A/C AMPLIFIER - BODY GROUND) |

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| OK | .gif) |

REPLACE A/C AMPLIFIER |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Blower Motor Circuit

Blower Motor Circuit

DESCRIPTION

The blower motor is operated by signals from the A/C amplifier. Blower motor

speed signals are transmitted in accordance with changes in the duty ratio.

WIRING DIAGRAM

CAUTION / NOT ...

Back-up Power Source Circuit

Back-up Power Source Circuit

DESCRIPTION

The back-up power source circuit for the A/C amplifier is shown below. Power

is supplied even when the ignition switch is turned off. The power is used for diagnostic

trouble code mem ...

Other materials about Toyota Venza:

No Signal from Transmitter ID1 (C2121/21-C2124/24,C2181/81-C2184/84)

DESCRIPTION

The tire pressure warning valve and transmitter installed in each tire and wheel

assembly measures the tire pressures. The measured values are transmitted as radio

waves to the tire pressure warning antenna and receiver on the body and then se ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL BRAKE PEDAL SUPPORT ASSEMBLY

(a) Install the brake pedal support assembly to the instrument panel

reinforcement with the bolt.

Torque:

19 N·m {195 kgf·cm, 14 ft·lbf}

...

Inspection

INSPECTION

PROCEDURE

1. INSPECT OUTER MIRROR SWITCH ASSEMBLY (w/o Memory)

(a) The L position of the left/right adjustment switch: Measure the resistance

according to the value(s) in the table below.

Standard Resistance (for Left Side):

Tes ...

0.1135

.gif)