Toyota Venza: Turn Signal Flasher Assembly

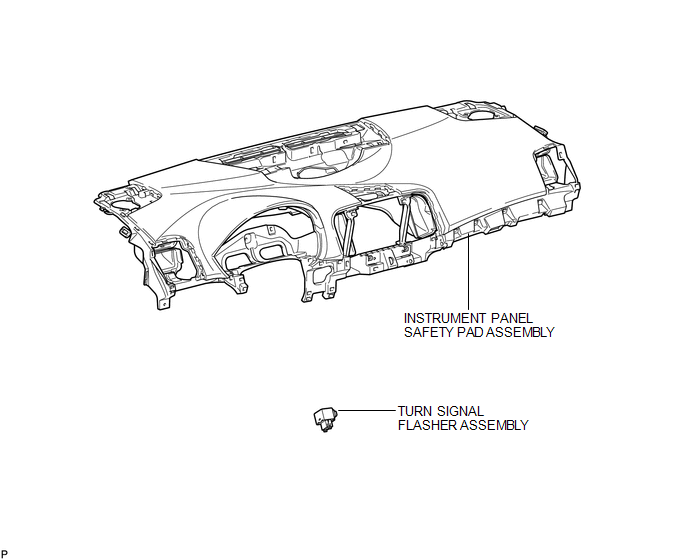

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT TURN SIGNAL FLASHER ASSEMBLY

|

(a) Disconnect the D34 turn signal flasher assembly connector. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D34-1 (IG) - Body ground |

Ignition switch off |

Below 1 V |

|

Ignition switch ON |

11 to 14 V |

|

|

D34-4 (B) - Body ground |

Always |

11 to 14 V |

|

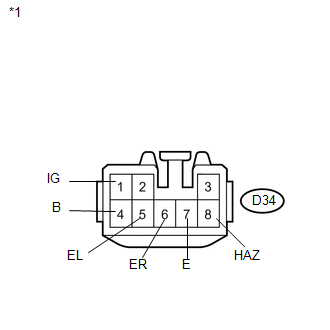

*1 |

Front view of wire harness connector (to Turn Signal Flasher Assembly) |

If the result is not as specified, repair or replace the wire harness or connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D34-5 (EL) - Body ground |

Turn signal switch off |

10 kΩ or higher |

|

Turn signal switch in left turn position |

Below 1 Ω |

|

|

D34-6 (ER) - Body ground |

Turn signal switch in neutral position |

10 kΩ or higher |

|

Turn signal switch in right turn position |

Below 1 Ω |

|

|

D34-7 (E) - Body ground |

Always |

Below 1 Ω |

|

D34-8 (HAZ) - Body ground |

Hazard warning switch off |

10 kΩ or higher |

|

Hazard warning switch on |

Below 1 Ω |

If the result is not as specified, repair or replace the wire harness or connector.

|

(d) Reconnect the D34 turn signal flasher assembly connector. |

|

(e) Measure the voltage according to the valve(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

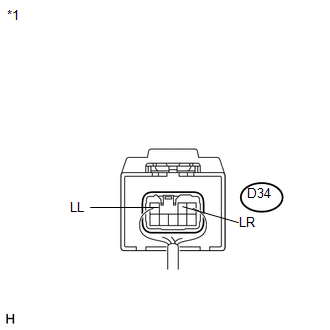

D34-2 (LR) - Body ground |

Hazard warning switch off |

Below 1 V |

|

Hazard warning switch on |

11 to 14 V (60 to 120 times per minute) |

|

|

Turn signal switch off |

Below 1 V |

|

|

Ignition switch ON and turn signal switch in RH position |

11 to 14 V (60 to 120 times per minute) |

|

|

D34-3 (LL) - Body ground |

Hazard warning switch off |

Below 1 V |

|

Hazard warning switch on |

11 to 14 V (60 to 120 times per minute) |

|

|

Turn signal switch off |

Below 1 V |

|

|

Ignition switch ON and turn signal switch in LH position |

11 to 14 V (60 to 120 times per minute) |

|

*1 |

Component with harness connected (Turn Signal Flasher Assembly) |

If the result is not as specified, replace the turn signal flasher assembly.

Removal

REMOVAL

PROCEDURE

1. REMOVE INSTRUMENT PANEL SAFETY PAD ASSEMBLY

HINT:

Refer to the procedure up to Remove Instrument Panel Safety Pad Assembly (See

page .gif) ).

).

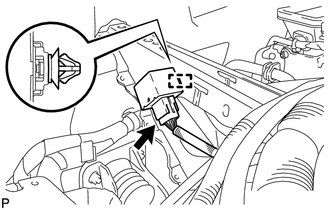

2. REMOVE TURN SIGNAL FLASHER ASSEMBLY

|

(a) Disconnect the connector. |

|

(b) Disengage the clamp and remove the turn signal flasher assembly.

Installation

INSTALLATION

PROCEDURE

1. INSTALL TURN SIGNAL FLASHER ASSEMBLY

|

(a) Engage the clamp to install the turn signal flasher assembly. |

|

(b) Connect the connector.

2. INSTALL INSTRUMENT PANEL SAFETY PAD ASSEMBLY

HINT:

Refer to the procedure from Install Instrument Panel Safety Pad Assembly (See

page .gif) ).

).

Stop Light Switch

Stop Light Switch

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE STOP LIGHT SWITCH ASSEMBLY

(a) Disconnect the connector.

...

Mirror (ext)

Mirror (ext)

...

Other materials about Toyota Venza:

Unlock Warning Switch Circuit

DESCRIPTION

The key unlock warning switch assembly turns on when the ignition key is inserted

into the ignition key cylinder and turns off when the ignition key is removed.

The main body ECU (driver side junction block assembly) operates the key confinemen ...

Speaker Circuit

DESCRIPTION

for 6 Speakers:

If there is a short in a speaker circuit, the navigation receiver assembly detects

it and stops output to the speakers.

Thus sound cannot be heard from the speakers even if there is no malfunction

in the navigation receiver a ...

Customize Parameters

CUSTOMIZE PARAMETERS

1. CUSTOMIZING FUNCTION WITH TECHSTREAM (REFERENCE)

HINT:

The following items can be customized.

NOTICE:

When the customer requests a change in a function, first make sure that

the function can be customized.

Record th ...

0.1615

.png)