Toyota Venza: Tire Pressure Warning Receiver

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

2. REMOVE ROOF SIDE INNER GARNISH ASSEMBLY LH

HINT:

- Refer to the procedures up to "Remove roof side inner garnish assembly"

(See page

.gif) ).

). - Removal should be performed only for the left side.

3. REMOVE TIRE PRESSURE WARNING ANTENNA AND RECEIVER

|

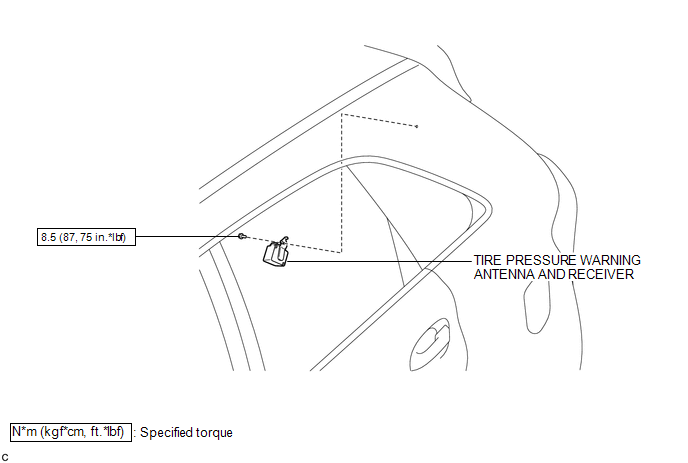

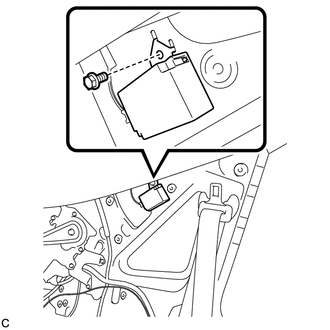

(a) Remove the bolt. |

|

|

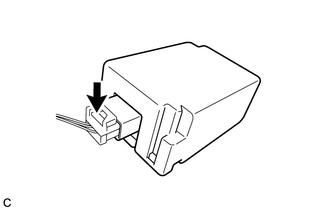

(b) Disconnect the connector to remove the tire pressure warning antenna and receiver. |

|

Installation

INSTALLATION

PROCEDURE

1. INSTALL TIRE PRESSURE WARNING ANTENNA AND RECEIVER

|

(a) Connect the connector. |

|

|

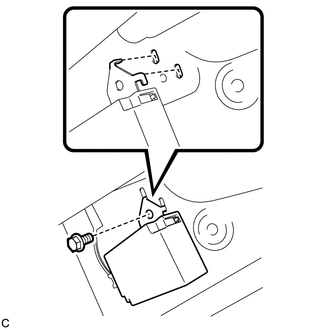

(b) Engage the 2 tabs into the holes as shown in the illustration to install the tire pressure warning antenna and receiver. |

|

(c) Install the bolt.

Torque:

8.5 N·m {87 kgf·cm, 75 in·lbf}

2. INSTALL ROOF SIDE INNER GARNISH ASSEMBLY LH

HINT:

- Refer to the procedures from "Install roof side inner garnish assembly"

(See page

.gif) ).

). - Installation should be performed only for the left side.

3. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

4. INSPECT TIRE PRESSURE WARNING SYSTEM

(a) Inspect the tire pressure warning system (See page

.gif) ).

).

Tire Pressure Warning Ecu

Tire Pressure Warning Ecu

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

Removal

REMOVAL

CAUTION / NOTICE / HINT

NOTICE:

Before removing the tire pressure warning ECU, read the registered transmitter

IDs of ...

Other materials about Toyota Venza:

Pressure Control Solenoid "D" Performance (Shift Solenoid Valve SLT) (P2714)

SYSTEM DESCRIPTION

The linear solenoid valve (SLT) controls the transmission line pressure for smooth

transmission operation based on signals from the throttle position sensor and the

vehicle speed sensor. The TCM adjusts the current to SLT solenoid valve ...

Indicator Circuit

DESCRIPTION

The headlight beam level control system indicator light in the combination meter

assembly comes on for approximately 3 seconds when the ignition switch is turned

to ON. The indicator light also comes on when the headlight leveling ECU assembly ...

Removal

REMOVAL

PROCEDURE

1. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY

HINT:

See the steps from "Remove Engine Assembly with transaxle" through "Remove Automatic

Transaxle Assembly" (See page ).

2. REMOVE AUTOMATIC TRANSAXLE OIL PAN SUB-ASSEMBLY

...

0.1601

.png)