Toyota Venza: Tire Pressure Warning Ecu

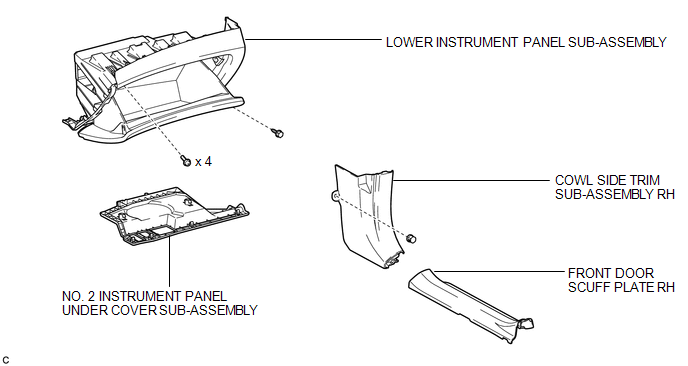

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

Removal

REMOVAL

CAUTION / NOTICE / HINT

NOTICE:

Before removing the tire pressure warning ECU, read the registered transmitter

IDs of all wheels and write them down to use for re-registration of transmitter

IDs (See page .gif) ).

).

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

2. REMOVE FRONT DOOR SCUFF PLATE RH

.gif)

3. REMOVE COWL SIDE TRIM SUB-ASSEMBLY RH

.gif)

4. REMOVE NO. 2 INSTRUMENT PANEL UNDER COVER SUB-ASSEMBLY

.gif)

5. REMOVE LOWER INSTRUMENT PANEL SUB-ASSEMBLY

.gif)

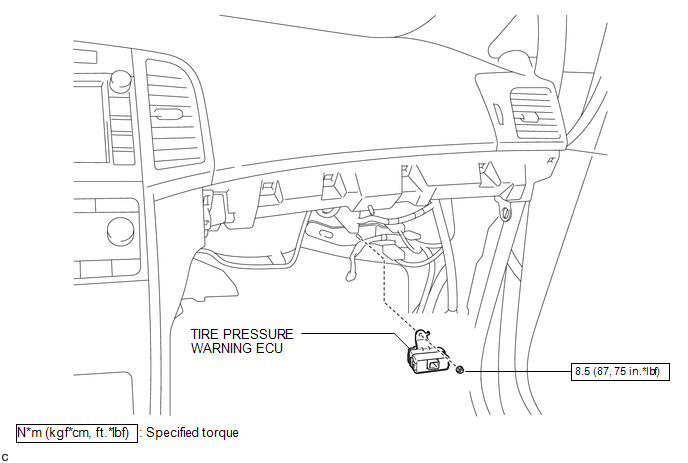

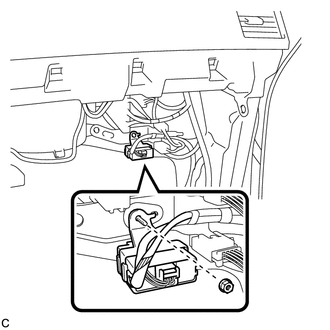

6. REMOVE TIRE PRESSURE WARNING ECU

|

(a) Remove the nut. |

|

|

(b) Disconnect the connector to remove the tire pressure warning ECU. |

|

Installation

INSTALLATION

PROCEDURE

1. INSTALL TIRE PRESSURE WARNING ECU

|

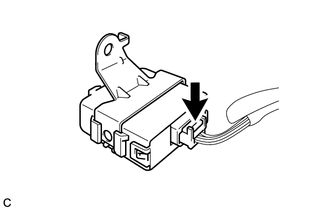

(a) Connect the connector to the tire pressure warning ECU. |

|

|

(b) Install the tire pressure warning ECU with the nut. Torque: 8.5 N·m {87 kgf·cm, 75 in·lbf} HINT: Engage the tab into the hole as shown in the illustration to install the tire pressure warning ECU. |

|

2. INSTALL LOWER INSTRUMENT PANEL SUB-ASSEMBLY

.gif)

3. INSTALL NO. 2 INSTRUMENT PANEL UNDER COVER SUB-ASSEMBLY

.gif)

4. INSTALL COWL SIDE TRIM SUB-ASSEMBLY RH

.gif)

5. INSTALL FRONT DOOR SCUFF PLATE RH

.gif)

6. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

7. REGISTER TRANSMITTER ID

HINT:

It is necessary to register all transmitter IDs (See page

.gif) ).

).

8. INSPECT TIRE PRESSURE WARNING SYSTEM

(a) Inspect the tire pressure warning system (See page

.gif) ).

).

Tire Pressure Warning Receiver

Tire Pressure Warning Receiver

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized ...

Other materials about Toyota Venza:

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Perform "Inspection After Repair" after replacing the camshaft, No. 2 camshaft,

camshaft timing gear assembly, camshaft timing exhaust gear assembly or cylinder

head sub-assembly (See page ).

PROCED ...

Installation

INSTALLATION

PROCEDURE

1. TEMPORARILY TIGHTEN FRONT DISC BRAKE BLEEDER PLUG

(a) Temporarily tighten the front disc brake bleeder plug.

HINT:

Fully tighten the front disc brake bleeder plug after bleeding any air left in

the system.

(b) Install the fron ...

Antenna location and effective range

- Antenna location

1. Antennas outside cabin

2. Antennas inside cabin

3. Antenna outside luggage compartment

- Effective range (areas within which the electronic key is detected)

When locking or unlocking the doors The system can be operat ...

0.1218

.png)