Toyota Venza: Removal

REMOVAL

PROCEDURE

1. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

See page .gif) for 2GR-FE

for 2GR-FE

See page .gif) for 1AR-FE

for 1AR-FE

2. REMOVE FRONT NO. 1 STABILIZER BRACKET LH

.gif)

3. REMOVE FRONT NO. 1 STABILIZER BRACKET RH

HINT:

Perform the same procedure as for the LH side.

4. REMOVE FRONT STABILIZER BAR WITH FRONT STABILIZER LINK ASSEMBLY

5. REMOVE STEERING LINK ASSEMBLY

.gif)

6. REMOVE FRONT FRAME ASSEMBLY (for 2GR-FE)

.gif)

7. SEPARATE REAR ENGINE MOUNTING INSULATOR ASSEMBLY (for 1AR-FE)

.gif)

8. REMOVE FRONT FRAME ASSEMBLY (for 1AR-FE)

.gif)

9. REMOVE STARTER ASSEMBLY (for 2GR-FE)

.gif)

10. REMOVE STARTER ASSEMBLY (for 1AR-FE)

.gif)

11. REMOVE MANIFOLD STAY (for 2GR-FE)

.gif)

12. REMOVE TRANSFER STIFFENER PLATE RH (for 2GR-FE)

.gif)

13. REMOVE TRANSFER STIFFENER PLATE RH (for 1AR-FE)

.gif)

14. SEPARATE WIRE HARNESS (for 2GR-FE)

.gif)

15. SEPARATE WIRE HARNESS (for 1AR-FE)

.gif)

16. REMOVE FLEXIBLE HOSE BRACKET SUB-ASSEMBLY (for 2GR-FE)

.gif)

17. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for 2GR-FE)

.gif)

18. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for 1AR-FE)

.gif)

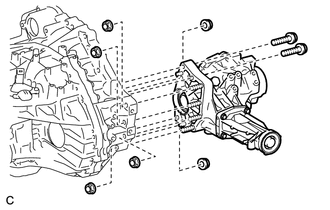

19. REMOVE TRANSFER ASSEMBLY

|

(a) Remove the 2 bolts and 6 nuts. |

|

(b) Using a plastic hammer, remove the transfer assembly from the transaxle assembly.

NOTICE:

- Remove the transfer assembly from the transaxle assembly without tilting it.

- During removal, do not hold the transfer assembly by the oil seals on either side of the assembly.

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE TRANSFER AND TRANSAXLE SETTING STUD BOLT

(a) Remove the 4 transfer and transaxle setting stud bolts.

2. RE ...

Other materials about Toyota Venza:

Window Glass Antenna Wire

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT WINDOW GLASS ANTENNA WIRE

(a) Check for continuity of the antenna.

HINT:

Check for continuity at the center of each antenna wire as shown in the

illustration.

N ...

Removal

REMOVAL

PROCEDURE

1. DRAIN AUTOMATIC TRANSAXLE FLUID

2. REMOVE FRONT FRAME ASSEMBLY

See page

3. SUPPORT ENGINE ASSEMBLY

4. REMOVE BELT

5. REMOVE AUTOMATIC TRANSAXLE OIL PAN SUB-ASSEMBLY

(a) Remove the 18 bolts and automatic transa ...

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL MAGNETIC CLUTCH ASSEMBLY

(a) Install the magnetic clutch stator while aligning the protrusion

on the stator with the notch on the air compressor assembly as shown in

the illustration.

...

0.1585