Toyota Venza: Removal

REMOVAL

PROCEDURE

1. RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM

.gif)

2. DISCHARGE FUEL SYSTEM PRESSURE

.gif)

3. PLACE FRONT WHEELS FACING STRAIGHT AHEAD

4. REMOVE FRONT WHEELS

5. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

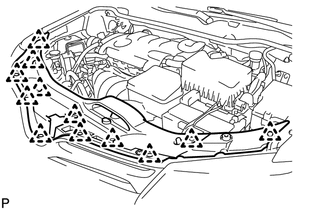

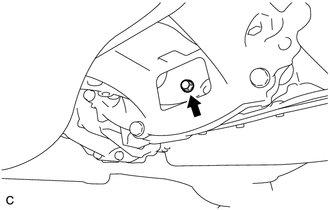

6. REMOVE COOL AIR INTAKE DUCT SEAL

|

(a) Remove the 12 clips and cool air intake duct seal. |

|

7. REMOVE NO. 1 ENGINE UNDER COVER

8. REMOVE NO. 2 ENGINE UNDER COVER

9. SEPARATE FRONT FENDER LINER LH

10. SEPARATE FRONT FENDER LINER RH

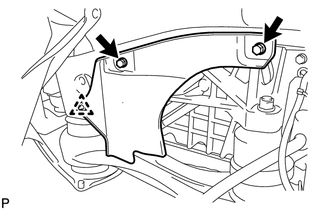

11. REMOVE FRONT FENDER APRON SEAL LH

|

(a) Remove the 2 bolts, clip and front fender apron seal LH. |

|

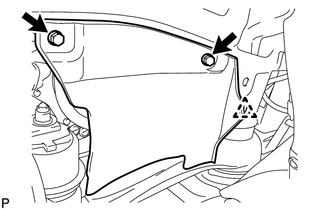

12. REMOVE FRONT FENDER APRON SEAL RH

|

(a) Remove the 2 bolts, clip and front fender apron seal RH. |

|

13. DRAIN ENGINE OIL

.gif)

14. DRAIN ENGINE COOLANT

.gif)

15. DRAIN AUTOMATIC TRANSAXLE FLUID (for 2WD)

.gif)

16. DRAIN AUTOMATIC TRANSAXLE FLUID (for AWD)

.gif)

17. DRAIN TRANSFER OIL (for AWD)

.gif)

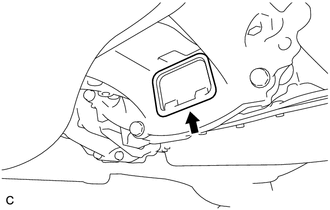

18. REMOVE FRONT WIPER ARM HEAD CAP

.gif)

19. REMOVE FRONT WIPER ARM AND BLADE ASSEMBLY LH

.gif)

20. REMOVE FRONT WIPER ARM AND BLADE ASSEMBLY RH

.gif)

21. REMOVE FRONT FENDER TO COWL SIDE SEAL LH

.gif)

22. REMOVE FRONT FENDER TO COWL SIDE SEAL RH

HINT:

Use the same procedure for the RH side and LH side.

23. REMOVE COWL TOP VENTILATOR LOUVER SUB-ASSEMBLY

.gif)

24. REMOVE WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

.gif)

25. REMOVE OUTER COWL TOP PANEL SUB-ASSEMBLY

.gif)

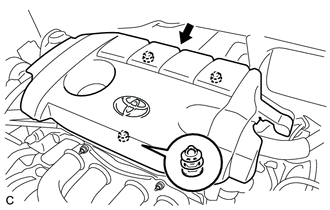

26. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

|

(a) Lift the rear of the No. 1 engine cover sub-assembly to detach the cover from the 2 pins, and then lift the front of the No. 1 engine cover sub-assembly to detach the cover from the pin and remove the No. 1 engine cover sub-assembly. NOTICE: Attempting to disengage both front and rear clips at the same time may cause the No. 1 engine cover sub-assembly to break. |

|

27. REMOVE BATTERY

|

(a) Remove the nut and separate the positive (+) battery terminal. |

|

(b) Loosen the nut and remove the bolt and battery clamp.

(c) Remove the battery and battery tray.

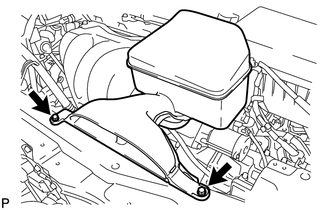

28. REMOVE INLET AIR CLEANER ASSEMBLY

|

(a) Remove the 2 bolts and inlet air cleaner assembly. |

|

29. REMOVE AIR CLEANER CAP SUB-ASSEMBLY

.gif)

30. REMOVE AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY

(a) Remove the air cleaner filter element sub-assembly.

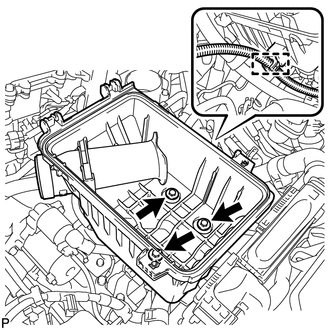

31. REMOVE AIR CLEANER CASE SUB-ASSEMBLY

|

(a) Disconnect the wire harness clamp. |

|

(b) Remove the 3 bolts and air cleaner case sub-assembly.

32. REMOVE AIR CLEANER BRACKET

|

(a) Remove the 2 bolts and air cleaner bracket. |

|

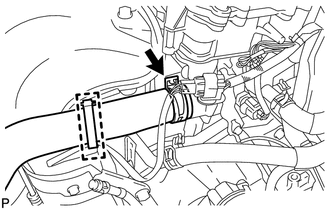

33. DISCONNECT NO. 1 RADIATOR HOSE

|

(a) Disconnect the wire harness clamp. |

|

(b) Disconnect the No. 1 radiator hose.

34. DISCONNECT NO. 2 RADIATOR HOSE

|

(a) Disconnect the No. 2 radiator hose. |

|

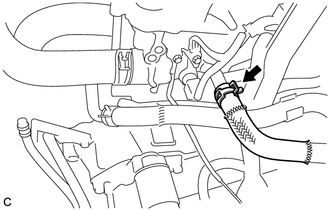

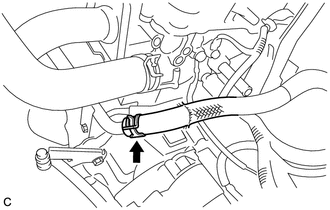

35. DISCONNECT INLET HEATER WATER HOSE

|

(a) Disconnect inlet heater water hose. |

|

36. DISCONNECT OUTLET HEATER WATER HOSE

|

(a) Disconnect outlet heater water hose. |

|

37. DISCONNECT FUEL TUBE SUB-ASSEMBLY

|

(a) Remove the No. 1 fuel pipe clamp. |

|

(b) Pinch the fuel tube connector and then pull out the fuel main tube.

NOTICE:

- Check for dirt and foreign objects on the pipe and around the connector. Clean if necessary and then disconnect the connector.

- Disconnect the connector by hand.

- Do not bend, fold or rotate the nylon tube.

- If the pipe and connector are stuck together, push and pull the connector until it becomes free.

- Put the pipe and connector ends in plastic bags to prevent damage and contamination.

38. DISCONNECT INLET NO. 1 OIL COOLER HOSE

|

(a) Disconnect the inlet No. 1 oil cooler hose. |

|

39. DISCONNECT OUTLET NO. 1 OIL COOLER HOSE

|

(a) Disconnect the outlet No. 1 oil cooler hose. |

|

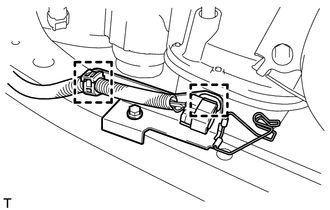

40. DISCONNECT TRANSMISSION CONTROL CABLE ASSEMBLY

|

(a) Remove the clip and nut, and disconnect the transmission control cable assembly from the transaxle. |

|

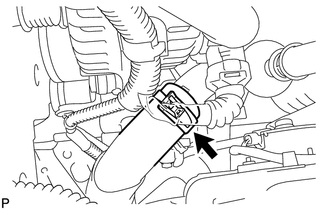

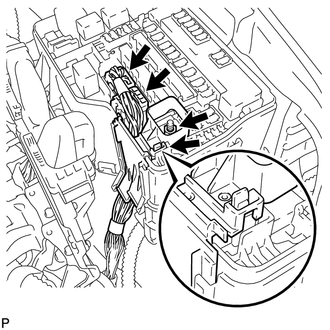

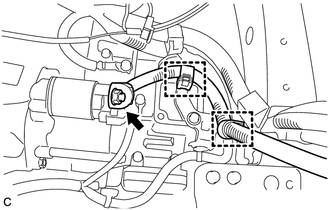

41. DISCONNECT ENGINE WIRE

(a) Remove the No. 1 relay block cover.

|

(b) Disconnect the 2 connectors. |

|

(c) Remove the nut.

(d) Using a screwdriver, unlock the claw and separate the engine wire from the engine room relay block.

|

(e) Disconnect the 2 engine wire clamps. |

|

(f) Remove the bolt and separate the ground cables.

|

(g) Disconnect the ground cable clamp. |

|

(h) Remove the 2 bolts and separate the ground cable.

|

(i) Remove the bolt and separate the ground cable. |

|

|

(j) Disconnect the 2 clamps, remove the nut and separate the positive (+) cable. |

|

|

(k) Pull up the lever to disconnect the ECM connector. |

|

(l) Disconnect the 2 clamps.

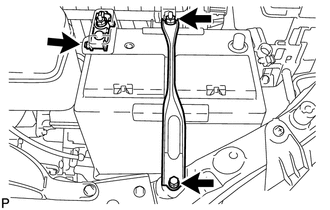

42. REMOVE NO. 2 ENGINE MOUNTING STAY RH

|

(a) Remove the 2 bolts and No. 2 engine mounting stay RH. |

|

43. REMOVE ENGINE MOVING CONTROL ROD

|

(a) Remove the 4 bolts and engine moving control rod. |

|

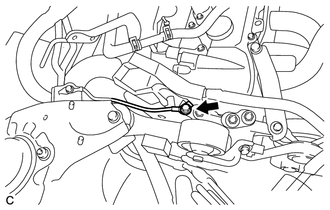

44. DISCONNECT UNION TO CHECK VALVE HOSE

|

(a) Disconnect the 2 union to check valve hoses. |

|

45. DISCONNECT SUCTION HOSE SUB-ASSEMBLY

.gif)

46. DISCONNECT COOLER REFRIGERANT DISCHARGE HOSE

.gif)

47. REMOVE TAIL EXHAUST PIPE ASSEMBLY (for AWD)

.gif)

48. REMOVE CENTER EXHAUST PIPE ASSEMBLY (for AWD)

.gif)

49. REMOVE PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY (for AWD)

.gif)

50. REMOVE FRONT EXHAUST PIPE ASSEMBLY

.gif)

51. SECURE STEERING WHEEL

.gif)

52. DISCONNECT STEERING INTERMEDIATE SHAFT SUB-ASSEMBLY

.gif)

53. REMOVE FRONT AXLE SHAFT NUT LH

.gif)

54. REMOVE FRONT AXLE SHAFT NUT RH

HINT:

Perform the same procedure as for the LH side.

55. SEPARATE FRONT SPEED SENSOR LH

.gif)

56. SEPARATE FRONT SPEED SENSOR RH

HINT:

Perform the same procedure as for the LH side.

57. SEPARATE TIE ROD ASSEMBLY LH

.gif)

58. SEPARATE TIE ROD ASSEMBLY RH

HINT:

Perform the same procedure as for the LH side.

59. SEPARATE FRONT STABILIZER LINK ASSEMBLY LH

.gif)

60. SEPARATE FRONT STABILIZER LINK ASSEMBLY RH

HINT:

Perform the same procedure as for the LH side.

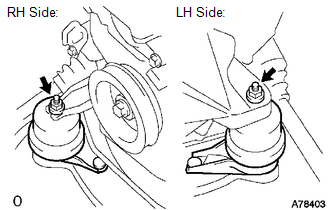

61. SEPARATE FRONT LOWER SUSPENSION ARM LH

.gif)

62. SEPARATE FRONT LOWER SUSPENSION ARM RH

HINT:

Perform the same procedure as for the LH side.

63. SEPARATE FRONT AXLE ASSEMBLY LH

.gif)

64. SEPARATE FRONT AXLE ASSEMBLY RH

HINT:

Perform the same procedure as for the LH side.

65. REMOVE FRONT DRIVE SHAFT ASSEMBLY LH

.gif)

66. REMOVE FRONT DRIVE SHAFT HOLE SNAP RING (for LH Side)

.gif)

67. REMOVE FRONT DRIVE SHAFT ASSEMBLY RH (for 2WD)

.gif)

68. REMOVE FRONT DRIVE SHAFT ASSEMBLY RH (for AWD)

.gif)

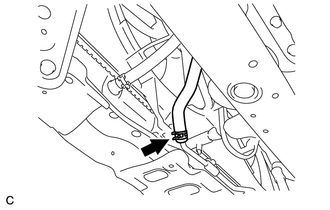

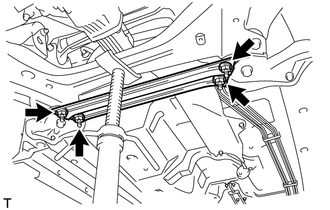

69. REMOVE FRONT FLOOR BRACE

|

(a) Remove the 4 nuts and front floor brace. |

|

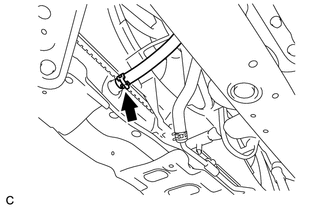

70. REMOVE FLYWHEEL HOUSING UNDER COVER

|

(a) Remove the flywheel housing under cover. |

|

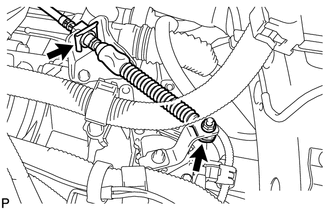

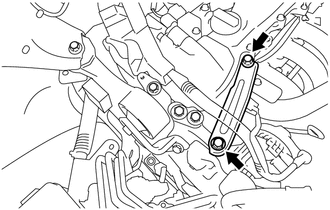

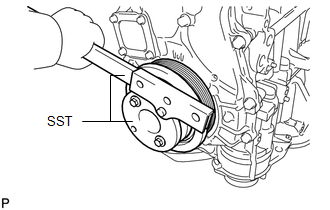

71. REMOVE DRIVE PLATE AND TORQUE CONVERTER SETTING BOLT

|

(a) Using SST, hold the crankshaft pulley. SST: 09213-54015 SST: 09330-00021 HINT: Part number of installation bolt for SST (crankshaft pulley holding tool): 91551-80650 (quantity: 2) |

|

|

(b) Remove the 6 drive plate and torque converter setting bolts. HINT: There will be one black colored bolt. |

|

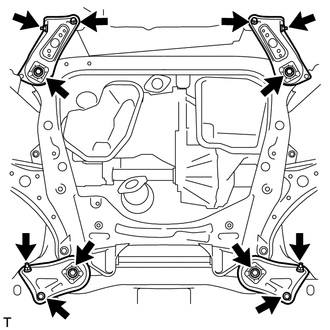

72. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

(a) Prepare an engine lifter.

|

(b) Remove the 4 bolts, 2 nuts, and frame side rail plates RH and LH. |

|

(c) Remove the 4 bolts, 2 nuts, and front suspension member rear braces RH and LH.

(d) Operate the engine lifter, then remove the engine assembly with transaxle from the vehicle.

NOTICE:

Make sure that the engine is clear of all wiring and hoses.

73. REMOVE NO. 1 FRONT STABILIZER BRACKET LH (for AWD)

.gif)

74. REMOVE NO. 1 FRONT STABILIZER BRACKET RH (for AWD)

HINT:

Perform the same procedure as for the LH side.

75. REMOVE FRONT STABILIZER BAR (for AWD)

76. REMOVE STEERING LINK ASSEMBLY (for AWD)

.gif)

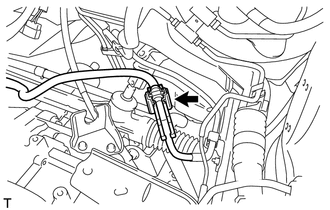

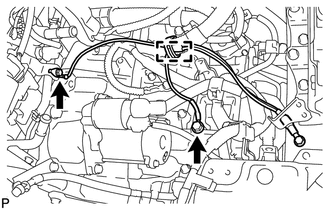

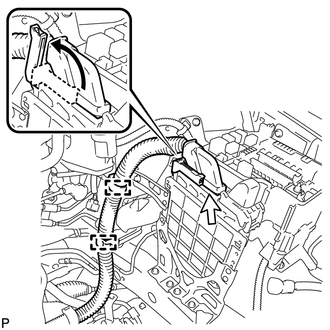

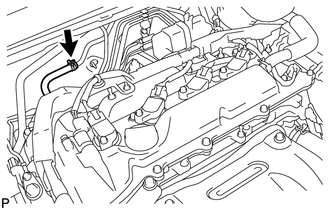

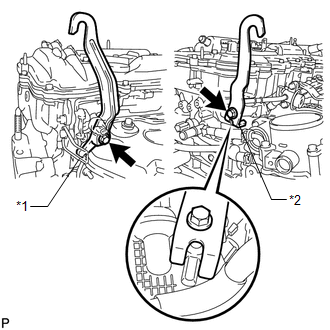

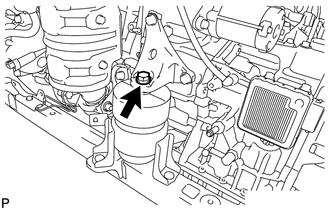

77. INSTALL ENGINE HANGERS

|

(a) Install the 2 engine hangers with the 2 bolts as shown in the illustration. Text in Illustration

Torque: 43 N·m {438 kgf·cm, 32 ft·lbf} HINT: Fit the fork part of the No. 2 engine hanger onto the rib of the cylinder head. |

|

(b) Attach the engine sling device and hang the engine with the chain block.

78. REMOVE V-RIBBED BELT

.gif)

79. REMOVE GENERATOR ASSEMBLY

.gif)

80. REMOVE COMPRESSOR ASSEMBLY WITH PULLEY

.gif)

81. REMOVE STARTER ASSEMBLY

.gif)

82. SEPARATE REAR ENGINE MOUNTING INSULATOR ASSEMBLY (for AWD)

|

(a) Remove the 2 bolts and separate the rear engine mounting insulator assembly from the rear engine mounting bracket. |

|

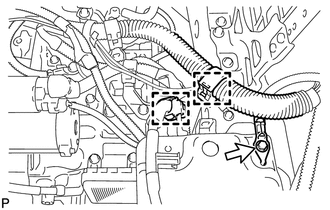

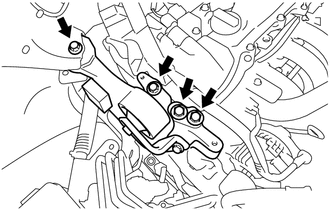

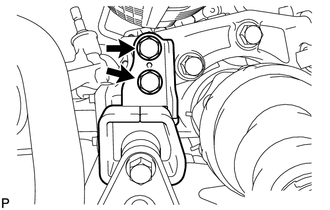

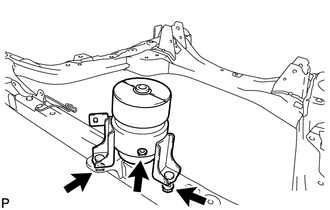

83. REMOVE FRONT FRAME ASSEMBLY

|

(a) Disconnect the 2 clamps with the engine wire. |

|

|

(b) Remove the 2 nuts and separate the engine mounting insulators RH and LH. |

|

|

(c) Remove the bolt and separate the front engine mounting insulator. |

|

(d) Remove the front frame assembly from the engine assembly with transaxle.

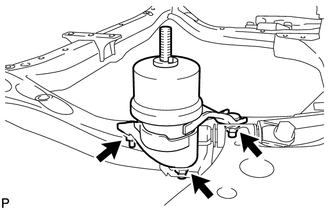

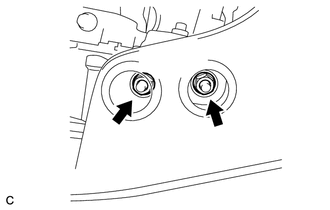

84. REMOVE FRONT ENGINE MOUNTING INSULATOR ASSEMBLY

|

(a) Remove the 2 hole plugs. |

|

(b) Remove the 3 nuts and front engine mounting insulator assembly.

HINT:

Perform this procedure only when replacement of the engine mounting insulator is necessary.

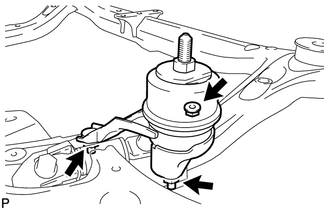

85. REMOVE ENGINE MOUNTING INSULATOR LH

|

(a) Remove the 2 hole plugs. |

|

(b) Remove the 3 nuts and engine mounting insulator LH.

HINT:

Perform this procedure only when replacement of the engine mounting insulator is necessary.

86. REMOVE ENGINE MOUNTING INSULATOR RH

|

(a) Remove the 2 hole plugs. |

|

(b) Remove the 3 nuts and engine mounting insulator RH.

HINT:

Perform this procedure only when replacement of the engine mounting insulator is necessary.

87. REMOVE REAR ENGINE MOUNTING INSULATOR ASSEMBLY (for AWD)

|

(a) Remove the 2 hole plugs. |

|

(b) Remove the 2 nuts and transverse engine mounting insulator.

HINT:

Perform this procedure only when replacement of the engine mounting insulator is necessary.

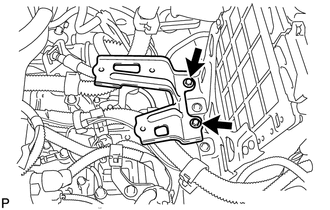

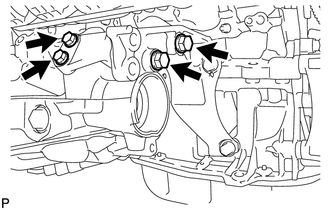

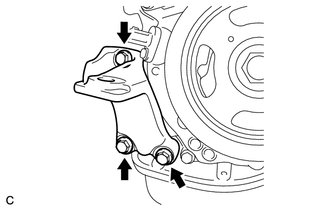

88. REMOVE TRANSFER STIFFENER PLATE RH (for AWD)

|

(a) Remove the 4 bolts and transfer stiffener plate RH. |

|

89. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for 2WD)

.gif)

90. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for AWD)

.gif)

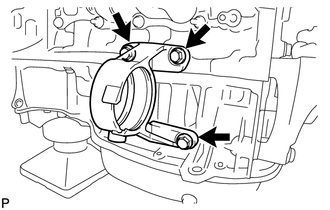

91. REMOVE ENGINE MOUNTING BRACKET RH

|

(a) Remove the 3 bolts and engine mounting bracket RH. |

|

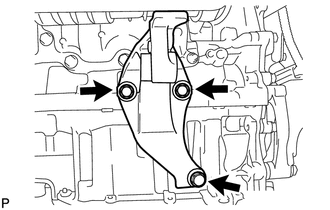

92. REMOVE DRIVE SHAFT BEARING BRACKET (for 2WD)

|

(a) Remove the 3 bolts and drive shaft bearing bracket. |

|

93. REMOVE REAR ENGINE MOUNTING BRACKET (for AWD)

|

(a) Remove the 3 bolts and rear engine mounting bracket. |

|

94. REMOVE DRIVE PLATE AND RING GEAR SUB-ASSEMBLY

.gif)

95. REMOVE ENGINE WIRE

(a) Remove the engine wire.

96. INSTALL ENGINE ON ENGINE STAND

(a) Install the engine onto an engine stand with the bolts.

97. REMOVE ENGINE HANGERS

|

(a) Remove the 2 bolts and No. 1 and No. 2 engine hangers. Text in Illustration

|

|

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Installation

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Perform "Inspection After Repair" after replacing the engine assembly (See page

).

PROCEDURE

1. INSTALL ENGINE HANGERS

2. REMOVE ENGINE ...

Other materials about Toyota Venza:

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

NOTICE:

In the table below, the values listed under "Normal Condition" are reference

values. Do not depend solely on these reference values when deciding whether a part

is faulty or not.

HINT:

Using the T ...

Fuel Injector Circuit

DESCRIPTION

The fuel injector assemblies are located on the intake manifold. They inject

fuel into the cylinders based on signals from the ECM.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system befo ...

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT FLUID LEVEL

(a) Check the fluid level.

Text in Illustration

*1

MAX Line

*2

MIN Line

HINT:

If brake ...

0.1769