Toyota Venza: Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL GENERATOR ROTOR ASSEMBLY

(a) Place the drive end frame on the clutch pulley.

|

(b) Install the generator rotor assembly to the drive end frame. |

|

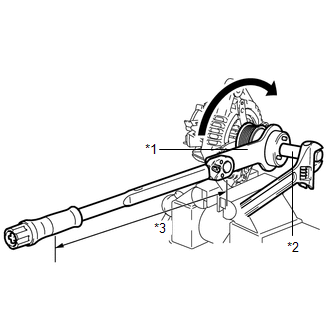

2. INSTALL GENERATOR CLUTCH PULLEY

(a) Temporarily install the clutch pulley onto the rotor shaft.

(b) Mount the generator drive end frame in a vise tightly.

|

(c) Confirm SST (A) and (B) shown in the illustration. Text in Illustration

SST: 09820-63021 |

|

|

(d) Place the rotor shaft end into SST (A). Text in Illustration

|

|

|

(e) Fit SST (B) to the clutch pulley. Text in Illustration

|

|

|

(f) Tighten the pulley by turning SST (B) in the direction shown in the illustration. Text in Illustration

Torque: without SST : 80 N·m {816 kgf·cm, 59 ft·lbf} with SST : 64 N·m {653 kgf·cm, 47 ft·lbf} NOTICE:

|

|

(g) Remove SST from the generator assembly.

(h) Check that the clutch pulley rotates smoothly.

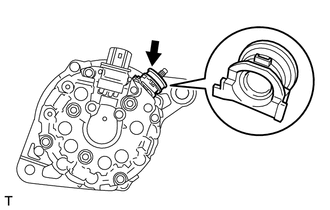

(i) Install a new clutch pulley cap to the clutch pulley.

3. INSTALL GENERATOR COIL ASSEMBLY

|

(a) Place a new generator washer on the generator rotor. |

|

|

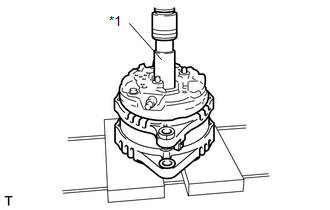

(b) Using a deep socket wrench (21 mm) and a press, slowly press in the generator coil assembly. Text in Illustration

|

|

|

(c) Install the 4 bolts. Torque: 5.9 N·m {60 kgf·cm, 52 in·lbf} |

|

4. INSTALL GENERATOR BRUSH HOLDER ASSEMBLY

|

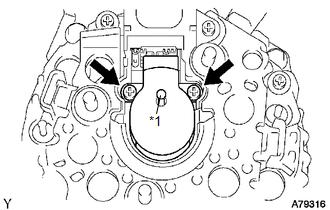

(a) While pushing the 2 brushes into the generator brush holder assembly, insert a 1.0 mm (0.0394 in.) pin into the brush holder hole. Text in Illustration

|

|

|

(b) Install the brush holder assembly to the generator coil with the 2 screws. Torque: 1.8 N·m {18 kgf·cm, 16 in·lbf} |

|

(c) Pull out the pin from the generator brush holder.

Text in Illustration|

*1 |

Pin |

5. INSTALL TERMINAL INSULATOR

|

(a) Install the terminal insulator to the generator coil. NOTICE: Be sure to install the terminal insulator in the correct direction. |

|

6. INSTALL GENERATOR REAR END COVER

|

(a) Install the generator rear end cover to the generator coil with the 3 nuts. Torque: 4.6 N·m {47 kgf·cm, 41 in·lbf} |

|

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL GENERATOR ASSEMBLY

(a) Install the wire harness clamp with the bolt.

Torque:

8.4 N·m {86 kgf·cm, 74 in·lbf}

...

Networking

Networking

...

Other materials about Toyota Venza:

Camshaft Position "A" Actuator Circuit (Bank 1) (P0010)

DESCRIPTION

The Variable Valve Timing (VVT) system adjusts the intake valve timing to improve

driveability. The engine oil pressure turns the VVT controller to adjust the valve

timing.

The camshaft timing oil control valve assembly is a solenoid valve an ...

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" ...

Key battery

Replace the battery with a new one if it is discharged.

- You will need the following items:

• Flathead screwdriver (To prevent damage to the key, cover the tip of the screwdriver

with rag.)

• Small Phillips-head screwdriver

• Lithium battery ...

0.1136

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)