Toyota Venza: Oil Pressure Switch

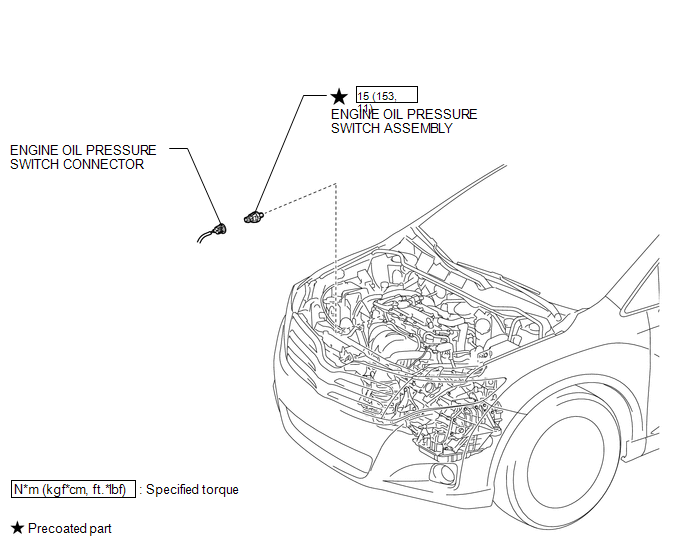

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

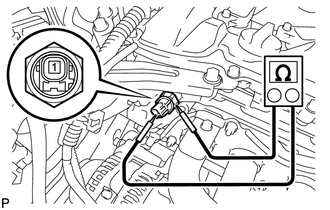

1. INSPECT ENGINE OIL PRESSURE SWITCH ASSEMBLY

(a) Disconnect the oil pressure switch connector.

(b) Start the engine.

|

(c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the oil pressure switch assembly. |

|

Removal

REMOVAL

PROCEDURE

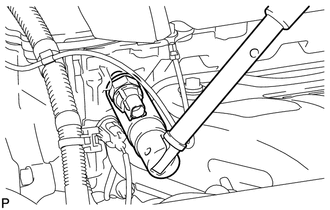

1. REMOVE ENGINE OIL PRESSURE SWITCH ASSEMBLY

|

(a) Disconnect the oil pressure switch connector. |

|

(b) Using a 24 mm deep socket wrench, remove the oil pressure switch.

Installation

INSTALLATION

PROCEDURE

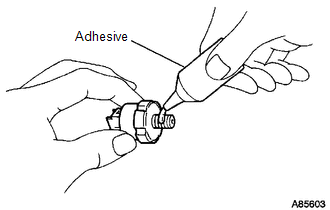

1. INSTALL ENGINE OIL PRESSURE SWITCH ASSEMBLY

|

(a) Apply adhesive to 2 or 3 threads of the oil pressure switch. Adhesive: TOYOTA Genuine Adhesive 1344, Three Bond 1344 or equivalent. NOTICE: Do not let adhesive adhere to the oil hole. |

|

|

(b) Using a 24 mm deep socket wrench, install the oil pressure switch. Torque: 15 N·m {153 kgf·cm, 11 ft·lbf} NOTICE: Do not start the engine within 1 hour of installation. |

|

(c) Connect the oil pressure switch connector.

2. INSPECT FOR OIL LEAK

.gif)

3. INSPECT ENGINE OIL LEVEL

.gif)

Replacement

Replacement

REPLACEMENT

CAUTION / NOTICE / HINT

CAUTION:

Prolonged and repeated contact with engine oil will result in the removal

of natural oils from the skin, leading to dryness, irritation and ...

Oil Pump

Oil Pump

...

Other materials about Toyota Venza:

Tire Pressure Warning Receiver

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page ).

2. REMOVE RO ...

Diagnosis System

DIAGNOSIS SYSTEM

1. DESCRIPTION

The main body ECU (driver side junction block assembly) and certification ECU

(smart key ECU assembly) control the LIN communication system. LIN communication

system data and Diagnostic Trouble Codes (DTCs) can be read thr ...

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Perform "Inspection After Repair" after replacing the camshaft, No. 2 camshaft,

camshaft timing gear assembly or camshaft timing exhaust gear assembly (See page

).

PROCEDURE

1. INSTALL NO. 2 CAMSHAF ...

0.113

.png)