Toyota Venza: Navigation Antenna

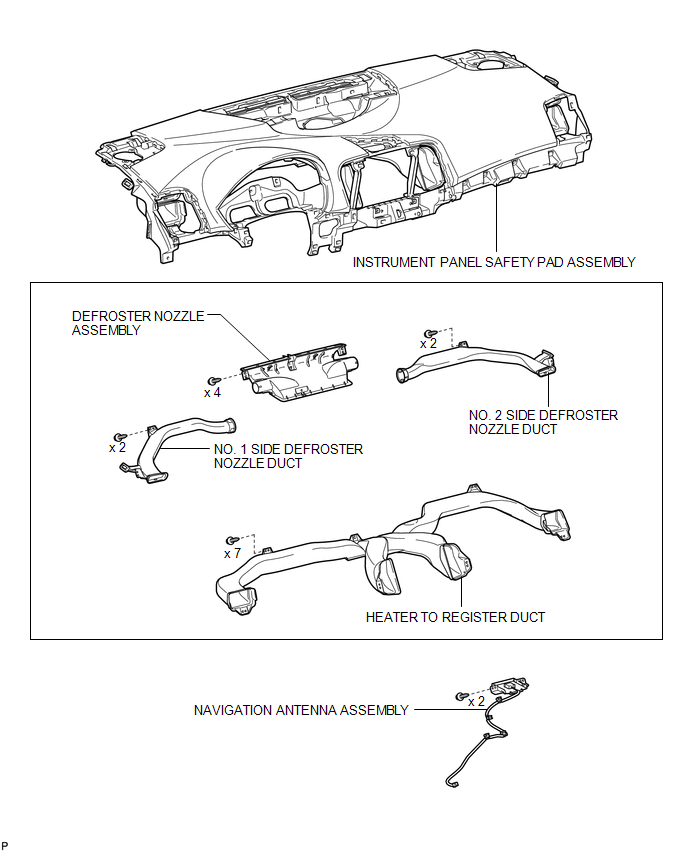

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE INSTRUMENT PANEL SAFETY PAD ASSEMBLY

HINT:

Refer to the procedure up to Remove Instrument Panel Safety Pad Assembly (See

page .gif) ).

).

2. REMOVE NO. 1 SIDE DEFROSTER NOZZLE DUCT

.gif)

3. REMOVE NO. 2 SIDE DEFROSTER NOZZLE DUCT

.gif)

4. REMOVE DEFROSTER NOZZLE ASSEMBLY

.gif)

5. REMOVE HEATER TO REGISTER DUCT

.gif)

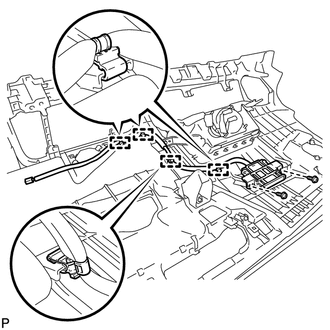

6. REMOVE NAVIGATION ANTENNA ASSEMBLY

|

(a) Disengage the 4 clamps. |

|

(b) Remove the 2 screws and the navigation antenna assembly.

Installation

INSTALLATION

PROCEDURE

1. INSTALL NAVIGATION ANTENNA ASSEMBLY

|

(a) Install the navigation antenna assembly with the 2 screws. |

|

(b) Engage the 4 clamps.

2. INSTALL HEATER TO REGISTER DUCT

.gif)

3. INSTALL DEFROSTER NOZZLE ASSEMBLY

.gif)

4. INSTALL NO. 2 SIDE DEFROSTER NOZZLE DUCT

.gif)

5. INSTALL NO. 1 SIDE DEFROSTER NOZZLE DUCT

.gif)

6. INSTALL INSTRUMENT PANEL SAFETY PAD ASSEMBLY

HINT:

Refer to the procedure from Install Roof Headlining Assembly (See page

.gif) ).

).

Other materials about Toyota Venza:

Removal

REMOVAL

PROCEDURE

1. PRECAUTION

NOTICE:

After turning the ignition switch off, waiting time may be required before disconnecting

the cable from the negative (-) battery terminal. Therefore, make sure to read the

disconnecting the cable from the negativ ...

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

Use these procedure to troubleshoot the sliding roof system.

*: Use the Techstream.

PROCEDURE

1.

VEHICLE BROUGHT TO WORKSHOP

NEXT

...

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

Rear View Monitor System

DTC Code

Detection Item

See page

C1622

Back Camera Disconnected

...

0.1416

.png)