Toyota Venza: Installation

INSTALLATION

PROCEDURE

1. INSTALL POWER STEERING ECU ASSEMBLY

|

(a) Engage the 4 wire harness clamps to the power steering ECU assembly. |

|

|

(b) Install the power steering ECU assembly with the 3 nuts. Torque: 14 N·m {138 kgf·cm, 10 ft·lbf} |

|

|

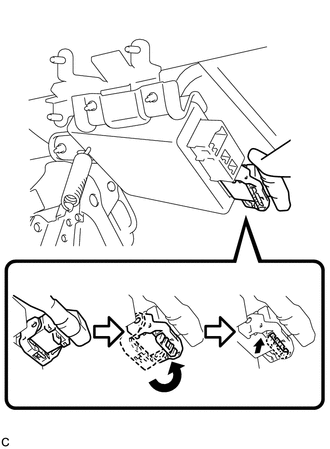

(c) Securely connect the connector to the power steering ECU assembly. HINT: Return the lock lever to its original position to connect the connector, and then securely push in the lock of the lock lever as shown in the illustration . |

|

|

(d) Connect the 3 connectors to the power steering ECU assembly. |

|

2. INSTALL DRIVER SIDE JUNCTION BLOCK ASSEMBLY

|

(a) Engage the 2 claws to install the driver side junction block assembly. |

|

(b) Connect the connectors to the back of the driver side junction block assembly.

|

(c) Install the driver side junction block assembly with the 3 nuts. Torque: 8.0 N·m {82 kgf·cm, 71 in·lbf} |

|

(d) Connect the connectors to the driver side junction block assembly.

3. INSTALL DRIVER SIDE KNEE AIRBAG ASSEMBLY

HINT:

Refer to the instructions for Installation of the knee airbag assembly (See page

.gif) ).

).

4. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

5. INITIALIZE ROTATION ANGLE SENSOR AND CALIBRATE TORQUE SENSOR ZERO POINT

(a) If replacing the power steering ECU assembly, clear the rotation angle sensor

calibration value, initialize the rotation angle sensor, and calibrate the torque

sensor zero point (See page .gif) ).

).

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

CAUTION:

Some of these service operations affect the SRS airbag system. Read the precautionary

notices concerning the SRS airbag system before servicing (See page

...

Other materials about Toyota Venza:

System Description

SYSTEM DESCRIPTION

1. ILLUMINATED ENTRY SYSTEM

(a) The illuminated entry system has the following control functions:

Control

Outline

Lights that Operate

Actuation Area-linked*2

When a registered k ...

Customize Parameters

CUSTOMIZE PARAMETERS

HINT:

The following items can be customized.

NOTICE:

When the customer requests a change in a function, first make sure that

the function can be customized.

Be sure to make a note of the current settings before customiz ...

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful bec ...

0.1272

.png)

.png)

.png)

.png)

.png)