Toyota Venza: How To Use This Manual

General Information

GENERAL INFORMATION

1. GENERAL DESCRIPTION

(a) This manual is written in accordance with SAE J2008.

(b) Repair operations can be separated mainly into the following 3 processes:

(1) Diagnosis

(2) Removing / Installing, Replacing, Disassembling / Reassembling, Checking and Adjusting

(3) Final Inspection

(c) The following procedure is omitted from this manual. However, this procedure must be performed.

(1) Use a jack or lift to perform operations.

(2) Clean all removed parts.

(3) Perform a visual check before and after performing any work.

2. INDEX

(a) An alphabetical INDEX section is provided at the end of the manual as a reference to help find the item to be repaired.

3. PREPARATION

(a) Use of Special Service Tools (SST) and Special Service Materials (SSM) may be required, depending on the repair procedure. Be sure to use SST and SSM when they are required and follow the work procedure properly. A list of SST and SSM is in the "Preparation" section of this manual.

4. REPAIR PROCEDURES

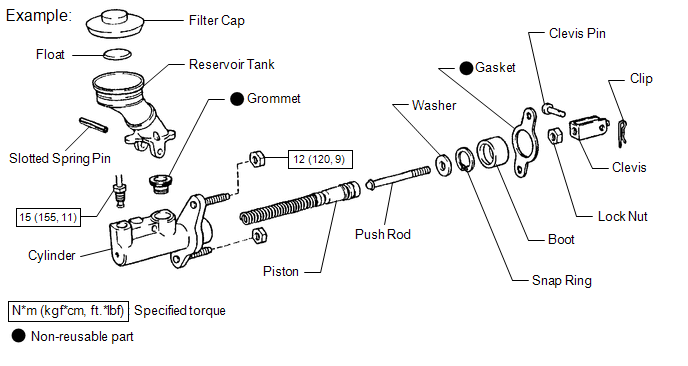

(a) A component illustration is placed under the title where necessary.

(b) Non-reusable parts, grease application areas, precoated parts and torque specifications are noted in the component illustrations.

- The following illustration is an example.

(c) Torque specifications, grease application areas and non-reusable parts are emphasized in the procedures.

HINT:

There are cases where such information can only be explained by using an illustration. In these cases, torque, oil and other information are described in the illustration.

(d) Only items with key points are described in the text. What to do and other details are explained using illustrations next to the text. Both the text and illustrations are accompanied by standard values and notices.

|

Illustration |

What to do and where to do it |

|

Task heading |

What work will be performed |

|

Explanation text |

|

(e) Illustrations of similar vehicle models are sometimes used. In these cases, minor details may be different from the actual vehicle.

(f) Procedures are presented in a step-by-step format.

5. SERVICE SPECIFICATIONS

(a) Specifications are presented in boldface text throughout the manual. The specifications are also found in the "Service Specifications" section for reference.

6. TERM DEFINITIONS

|

CAUTION |

Possibility of injury to you or other people. |

|

NOTICE |

Possibility of damage to components being repaired. |

|

HINT |

Provides additional information to help you perform repairs. |

7. INTERNATIONAL SYSTEM OF UNITS

(a) The units used in this manual comply with the International System of Units (SI UNIT) standard. Other units from the metric system and the English systems are also provided.

- Example:

Torque:

30 N·m {310 kgf·cm, 22 ft·lbf}

How To Proceed With Troubleshooting

How To Proceed With Troubleshooting

HOW TO PROCEED WITH TROUBLESHOOTING

1. OPERATION FLOW

HINT:

Perform troubleshooting in accordance with the procedure below. The following

is an outline of basic troubleshooting procedure. Confirm ...

Identification Information

Identification Information

Vehicle Identification And Serial Numbers

VEHICLE IDENTIFICATION AND SERIAL NUMBERS

1. VEHICLE IDENTIFICATION NUMBER

(a) The vehicle identification number is stamped on the vehicle body and on th ...

Other materials about Toyota Venza:

System Description

SYSTEM DESCRIPTION

1. GENERAL

(a) This system uses ultrasonic sensors to detect any obstacles at the corners

and the rear of the vehicle. The system then informs the driver of the distance

between the sensors and an obstacle as well as their positions by ...

Terminals Of Ecu

TERMINALS OF ECU

1. CHECK MAIN BODY ECU (DRIVER SIDE JUNCTION BLOCK ASSEMBLY)

(a) Disconnect the 2F and 2C driver side junction block connectors.

(b) Disconnect the D50 and D51 main body ECU connectors.

(c) Measure the resistance and voltage according to ...

Differential Mount Cushion

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL REAR NO. 1 DIFFERENTIAL MOUNT CUSHION

(a) Using SST, install a new rear No. 1 differential mount cushion.

Text in Illustration

*1

Protrusion ...

0.1453