Toyota Venza: Fuel Sender Gauge Assembly

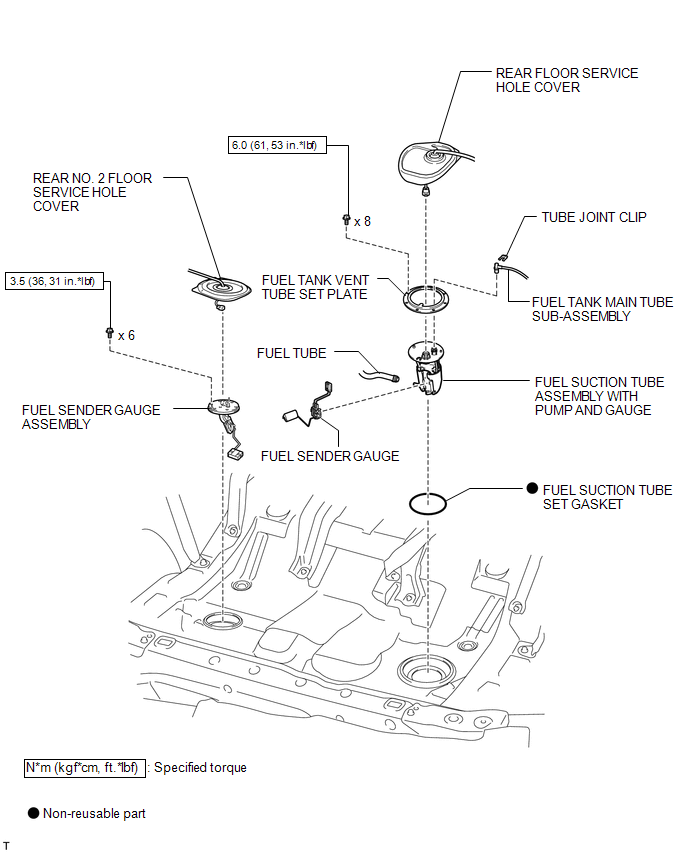

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. DISCHARGE FUEL SYSTEM PRESSURE

(a) Discharge fuel system pressure (See page

.gif) ).

).

2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

3. REMOVE FUEL SUCTION TUBE ASSEMBLY WITH PUMP AND GAUGE

(a) Remove the fuel suction tube assembly with pump and gauge (See page

.gif) ).

).

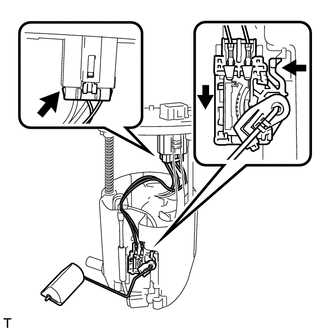

4. REMOVE FUEL SENDER GAUGE

|

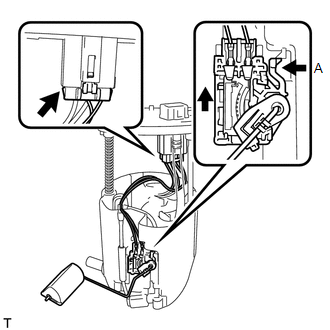

(a) Disconnect the fuel sender gauge connector from the fuel suction plate. |

|

(b) Press down on the fuel sender gauge claw labeled A. Then slide the fuel sender gauge upward.

NOTICE:

Do not touch the sender resistance plate or contact area.

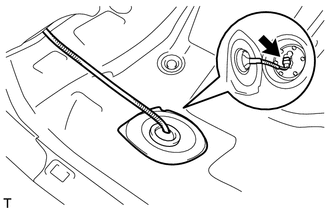

5. REMOVE REAR NO. 2 FLOOR SERVICE HOLE COVER

|

(a) Remove the rear No. 2 floor service hole cover. |

|

(b) Disconnect the fuel sender gauge connector.

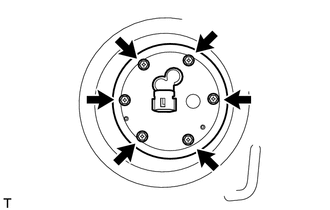

6. REMOVE FUEL SENDER GAUGE ASSEMBLY

|

(a) Remove the 6 bolts and fuel sender gauge assembly from the fuel tank. NOTICE: Be careful not to bend the arm of the fuel sender gauge. |

|

Inspection

INSPECTION

PROCEDURE

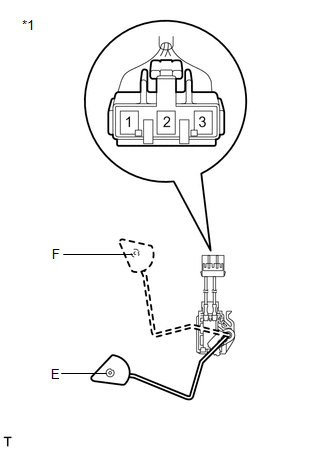

1. INSPECT FUEL SENDER GAUGE

Text in Illustration

Text in Illustration

|

*1 |

Component without harness connected (Fuel Sender Gauge) |

(a) Remove the fuel sender gauge.

(b) Check that the float moves smoothly between F and E.

(c) Measure the resistance between terminals 2 and 1 of the connector according to the value(s) in the table below.

Standard Resistance:

|

Float Level |

Resistance (Ω) |

|---|---|

|

F |

6.5 to 8.5 |

|

Between E and F |

6.5 to 187.2 (Gradually changes) |

|

E |

183.2 to 187.2 |

If the result is not as specified, replace the fuel sender gauge.

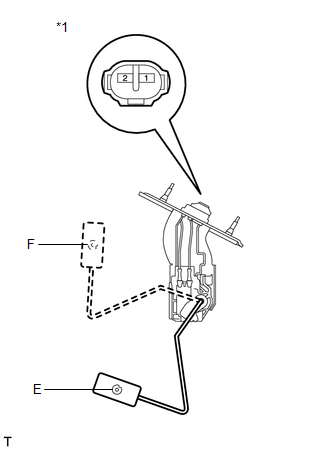

2. INSPECT FUEL SENDER GAUGE ASSEMBLY

Text in Illustration

Text in Illustration

|

*1 |

Component without connected (Fuel Sender Gauge Assembly) |

(a) Remove the fuel sender gauge assembly.

(b) Check that the float moves smoothly between F and E.

(c) Measure the resistance between terminals 1 and 2 according to the value(s) in the table below.

Standard Resistance:

|

Float Level |

Resistance (Ω) |

|---|---|

|

F |

6.5 to 8.5 |

|

Between E and F |

6.5 to 227.3 (Gradually changes) |

|

E |

222.3 to 227.3 |

If the result is not as specified, replace the fuel sender gauge assembly.

Installation

INSTALLATION

PROCEDURE

1. INSTALL FUEL SENDER GAUGE ASSEMBLY

|

(a) Install the fuel sender gauge assembly to the fuel tank with the 6 bolts. Torque: 3.5 N·m {36 kgf·cm, 31 in·lbf} NOTICE: Be careful not to bend the arm of the fuel sender gauge assembly. |

|

2. INSTALL REAR NO. 2 FLOOR SERVICE HOLE COVER

|

(a) Connect the fuel sender gauge connector. |

|

(b) Install the rear No. 2 floor service hole cover with new butyl tape.

3. INSTALL FUEL SENDER GAUGE

|

(a) Install the fuel sender gauge by sliding it downward. NOTICE: Make sure that the fuel sender gauge arm does not bend. |

|

(b) Connect the connector of the fuel sender gauge.

NOTICE:

Do not damage the wire harness.

4. INSTALL FUEL SUCTION TUBE ASSEMBLY WITH PUMP AND GAUGE

(a) Install the fuel suction tube assembly with pump and gauge (See page

.gif) ).

).

5. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

6. INSPECT FOR FUEL LEAK

.gif)

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL FUEL SUCTION TUBE ASSEMBLY WITH PUMP AND GAUGE

(a) Install a new fuel suction tube set gasket onto the fuel tank.

(b) Connect the fuel tube with the cl ...

Fuel System

Fuel System

...

Other materials about Toyota Venza:

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms. If multiple

suspected areas are listed, the potential causes of the symptoms are listed in order

of probability in the "Suspected Area" column of ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL DRIVE MONITOR SWITCH

(a) Engage the 4 claws to install the driver monitor switch.

2. INSTALL RADIO AND DISPLAY RECEIVER ASSEMBLY WITH BRACKET (for Radio and Display ...

Inspection

INSPECTION

PROCEDURE

1. INSPECT STARTER ASSEMBLY

NOTICE:

These tests must be performed within 3 to 5 seconds to avoid burning out the

coil.

(a) Perform a pull-in test.

(1) Remove the nut and disconnect the lead wire from terminal C.

(2) Con ...

0.13

.png)

.png)