Toyota Venza: Front Blower Motor

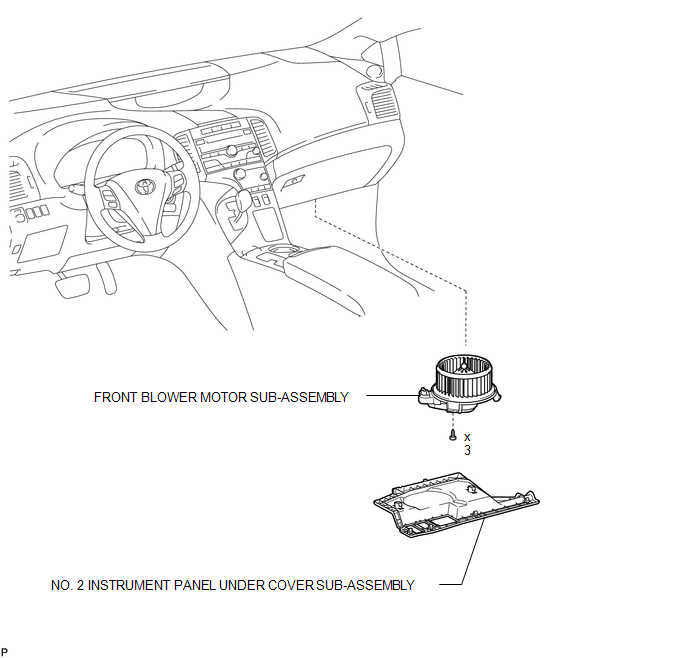

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

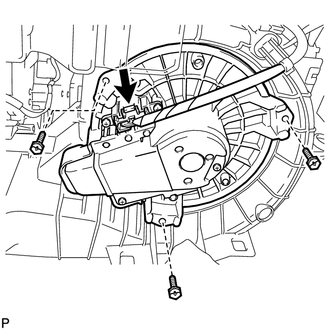

1. INSTALL FRONT BLOWER MOTOR SUB-ASSEMBLY

|

(a) Install the front blower motor sub-assembly with the 3 screws. |

|

(b) Connect the connector.

2. INSTALL NO. 2 INSTRUMENT PANEL UNDER COVER SUB-ASSEMBLY

.gif)

3. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

2. REMOVE NO. 2 INSTRUMENT PANEL UNDER COVER SUB-ASSEMBLY

.gif)

3. REMOVE FRONT BLOWER MOTOR SUB-ASSEMBLY

|

(a) Disconnect the connector. |

|

(b) Remove the 3 screws and front blower motor sub-assembly.

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL COOLER DRYER

(a) Using pliers, install a new cooler dryer to the modulator.

(b) Apply sufficien ...

Other materials about Toyota Venza:

Steering Position Sensor Malfunction (B2414)

DESCRIPTION

The AFS ECU (headlight swivel ECU assembly) receives signals indicating the swerve-angle

from the steering angle sensor using CAN communication.

DTC No.

DTC Detection Condition

Trouble Area

B241 ...

Inspection

INSPECTION

PROCEDURE

1. INSPECT REAR DRIVE SHAFT ASSEMBLY

(a) Check whether the drive shaft dimensions are within the following

specifications.

HINT:

The following table shows the dimension (A) of the drive shaft.

Dimension (A)

...

Driver Side Door Entry Unlock Function does not Operate

DESCRIPTION

If the driver door entry lock function operates normally, but its entry unlock

function does not, this means that the request code from the driver door is being

output normally. In this case, a malfunction in the touch sensor circuit (from the ...

0.112

.png)