Toyota Venza: Engine Oil Cooler

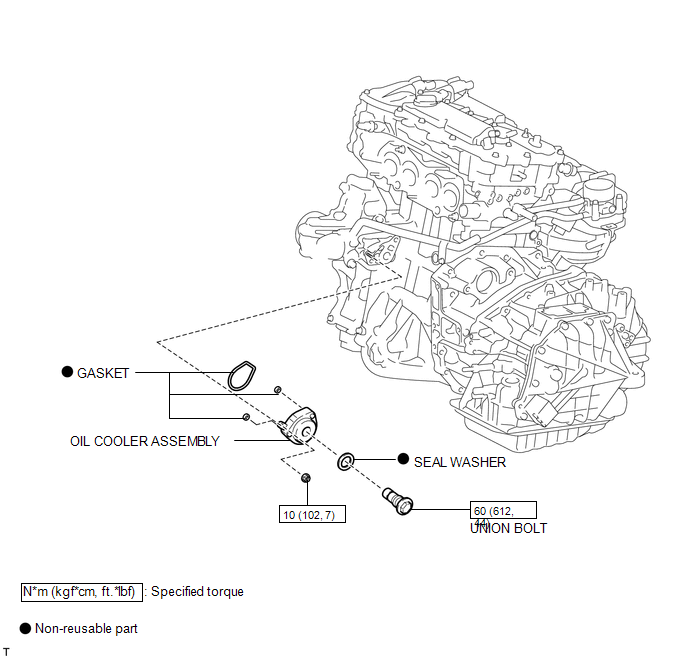

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE EXHAUST MANIFOLD ASSEMBLY

HINT:

See page .gif)

2. DRAIN ENGINE OIL

.gif)

3. DRAIN ENGINE COOLANT

.gif)

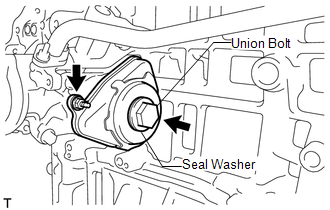

4. REMOVE OIL COOLER ASSEMBLY

|

(a) Remove the nut, union bolt, seal washer and oil cooler assembly. |

|

(b) Remove the 3 gaskets from the oil cooler assembly.

Inspection

INSPECTION

PROCEDURE

1. INSPECT ENGINE OIL COOLER

(a) Visually check the engine oil cooler for cracks or damage.

If cracks or damage are found, replace the engine oil cooler.

Installation

INSTALLATION

PROCEDURE

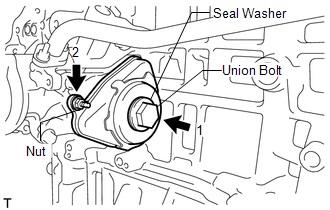

1. INSTALL OIL COOLER ASSEMBLY

(a) Clean the oil cooler contact surface on the cooler mounting.

(b) Apply a light coat of engine oil to 3 new gaskets.

(c) Install the 3 new gaskets to the oil cooler assembly.

(d) Temporarily install the oil cooler assembly with the union bolt, nut and a new seal washer.

|

(e) Tighten the bolt and nut in several steps, in the sequence shown in the illustration. Torque: Union Bolt : 60 N·m {612 kgf·cm, 44 ft·lbf} Nut : 10 N·m {102 kgf·cm, 7 ft·lbf} |

|

2. INSTALL EXHAUST MANIFOLD ASSEMBLY

HINT:

See page .gif)

3. ADD ENGINE OIL

.gif)

4. ADD ENGINE COOLANT

.gif)

5. INSPECT FOR OIL LEAK

.gif)

6. INSPECT ENGINE OIL LEVEL

.gif)

Lubrication System

Lubrication System

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT ENGINE OIL LEVEL

(a) Warm up the engine, stop it and wait 5 minutes. The engine oil level should

be between the low level mark ...

Other materials about Toyota Venza:

TRAC OFF Indicator Light Remains ON

DESCRIPTION

The skid control ECU is connected to the combination meter via CAN communication.

Pressing the VSC OFF switch turns off traction control and pressing and holding

this switch turns off traction and VSC controls. If TRAC control is turned off,

...

Customize Parameters

CUSTOMIZE PARAMETERS

1. CUSTOMIZING FUNCTION WITH TECHSTREAM

HINT:

The following items can be customized.

NOTICE:

When the customer requests a change in a function, first make sure that

the function can be customized.

Be sure to make a not ...

Luggage compartment light

1. Door position

2. Off

- Adjusting the rear personal/interior lights angle

Push the edge of the light lens.

- To prevent the battery from being discharged

►Vehicles with smart key system

If the personal/interior lights and “ENGIN ...

0.1354