Toyota Venza: Unlock Warning Switch Circuit

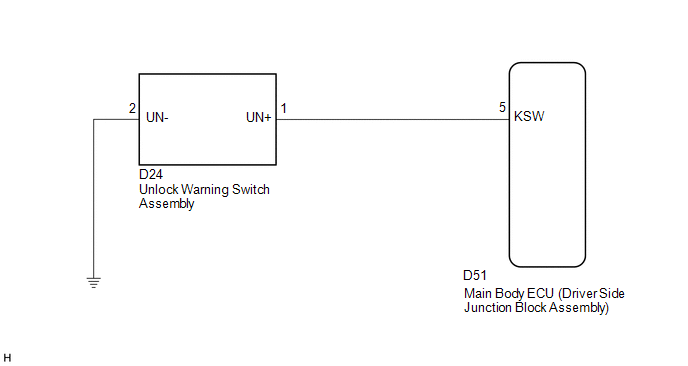

DESCRIPTION

The key unlock warning switch assembly turns on when the ignition key is inserted into the ignition key cylinder and turns off when the ignition key is removed.

The main body ECU (driver side junction block assembly) operates the key confinement prevention function while the key unlock warning switch assembly is on.

WIRING DIAGRAM

PROCEDURE

|

1. |

READ VALUE USING TECHSTREAM (UNLOCK WARNING SWITCH ASSEMBLY) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Select the item below in the Data List and then read the display on the Techstream.

Main Body|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

Key Unlock Warning SW |

Unlock warning switch signal/ON or OFF |

ON: Key inserted into ignition key cylinder OFF: Key removed from ignition key cylinder |

- |

OK:

When the key is in the ignition key cylinder, ON appears on the Techstream.

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

|

|

2. |

INSPECT UNLOCK WARNING SWITCH ASSEMBLY |

|

(a) Remove the unlock warning switch assembly (See page

|

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D24-1 (UN+) - D24-2 (UN-) |

Free (Key removed) |

10 kΩ or higher |

|

D24-1 (UN+) - D24-2 (UN-) |

Pushed (Key set) |

Below 1 Ω |

|

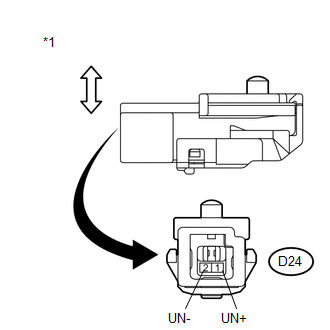

*1 |

Component without harness connected (Unlock Warning Switch Assembly) |

| NG | .gif) |

REPLACE UNLOCK WARNING SWITCH ASSEMBLY |

|

|

3. |

CHECK HARNESS AND CONNECTOR (UNLOCK WARNING SWITCH ASSEMBLY - BODY GROUND) |

|

(a) Disconnect the D24 unlock warning switch assembly connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D24-2 (UN-) - Body ground |

Always |

Below 1 Ω |

|

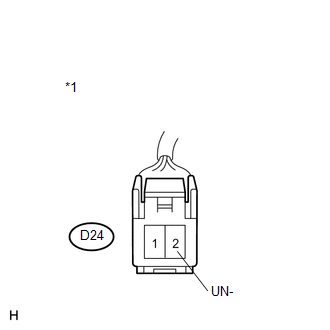

*1 |

Front view of wire harness connector (to Unlock Warning Switch Assembly) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

CHECK HARNESS AND CONNECTOR (UNLOCK WARNING SWITCH ASSEMBLY - MAIN BODY ECU) |

|

(a) Disconnect the D51 main body ECU (driver side junction block assembly) connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D24-1 (UN+) - D51-5 (KSW) |

Always |

Below 1 Ω |

|

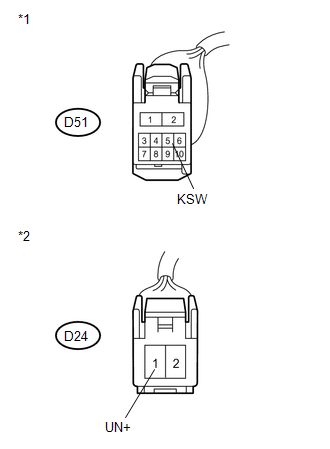

*1 |

Front view of wire harness connector (to Main Body ECU (Driver Side Junction Block Assembly)) |

|

*2 |

Front view of wire harness connector (to Unlock Warning Switch Assembly) |

| OK | .gif) |

REPLACE MAIN BODY ECU (DRIVER SIDE JUNCTION BLOCK ASSEMBLY) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

ECU Power Source Circuit

ECU Power Source Circuit

DESCRIPTION

This circuit provides power for main body ECU (driver side junction block assembly)

operation.

WIRING DIAGRAM

PROCEDURE

1.

CHECK DRIVER SIDE JUNCTION BLOCK A ...

Transponder Key Amplifier

Transponder Key Amplifier

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT DOOR SCUFF PLATE

2. REMOVE COWL SIDE TRIM SUB-ASSEMBLY

3. REMOVE LOWER NO. 1 INSTRUMENT PANEL FINISH PA ...

Other materials about Toyota Venza:

Using the AUX port/USB port

This port can be used to connect a portable audio device and listen to it

through the vehicle’s speakers.

Open the cover.

Connect the portable audio device.

- Operating portable audio devices connected to the audio system

The volume can be adj ...

Front Seat Inner Belt Assembly

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT FRONT SEAT INNER BELT ASSEMBLY LH (w/ Seat Position Memory System)

(a) Measure the resistance according to the value(s) in the table below.

...

Replacement

REPLACEMENT

PROCEDURE

1. REMOVE CENTER EXHAUST PIPE ASSEMBLY

(a) Remove the center exhaust pipe assembly.

HINT:

Refer to the instructions for Removal of the exhaust pipe (See page

for 2GR-FE,

for 1AR-FE).

2. REMOVE PROPELLER WITH CENTER BEARING SHAF ...

0.1423

.gif)

.gif) ).

).