Toyota Venza: Terminals Of Ecu

TERMINALS OF ECU

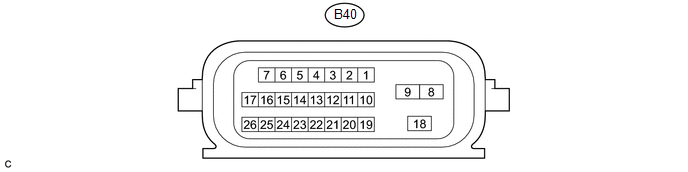

1. TCM

HINT:

Each TCM terminal standard voltage is shown in the table below.

In the table, first follow the information under "Condition". Look under "Terminal No. (Symbol)" for the terminals to be inspected. The standard voltage between the terminals is shown under "Specified Condition".

Use the illustration above as a reference for the TCM terminals.

|

Terminal No. (Symbol) |

Wiring Color |

Terminal Description |

Condition |

Specified Condition |

|---|---|---|---|---|

|

B40-15 (R) - B40-8 (E1) |

G - B |

R shift position switch signal |

Ignition switch ON and shift lever in R |

11 to 14 V |

|

Ignition switch ON and shift lever in any position except R |

Below 1 V |

|||

|

B40-16 (D) - B40-8 (E1) |

LG - B |

D shift position switch signal |

Ignition switch ON and shift lever in D and S |

11 to 14 V |

|

Ignition switch ON and shift lever in any position except D and S |

Below 1 V |

|||

|

B40-12 (STP) - B40-8 (E1) |

P - B |

Stop light switch signal |

Brake pedal is depressed |

7.5 to 14 V |

|

Brake pedal is released |

Below 1.5 V |

|||

|

B40-11 (NSW) - B40-8 (E1) |

GR - B |

Park/neutral switch signal |

Ignition switch ON and shift lever in P or N |

Below 2 V |

|

Ignition switch ON and shift lever in any position except P or N |

11 to 14 V |

|||

|

B40-10 (STA) - B40-8 (E1) |

V - B |

Starter signal |

Cranking (shift lever in P or N, engine switch START) |

11 to 14 V |

|

Ignition switch ON and shift lever in any position except P or N |

Below 2 V |

|||

|

B40-3 (SPD) - B40-8 (E1) |

L - B |

Speed signal from combination meter |

Vehicle speed 20 km/h (12 mph) |

Pulse generation (see waveform 1) |

|

B40-1 (BATT) - B40-8 (E1) |

W-L - B |

Battery (for measuring battery voltage and for TCM memory) |

Always |

9 to 14 V |

|

B40-13 (IGSW) - B40-8 (E1) |

Y - B |

Ignition switch |

Ignition switch ON |

9 to 14 V |

|

B40-18 (+B) - B40-8 (E1) |

Y - B |

Power source of TCM |

Ignition switch ON |

9 to 14 V |

|

B40-6 (CAN+) - B40-8 (E1) |

R - B |

CAN communication line |

Ignition switch ON |

Pulse generation (see waveform 2) |

|

B40-7 (CAN-) - B40-8 (E1) |

W - B |

CAN communication line |

Ignition switch ON |

Pulse generation (see waveform 3) |

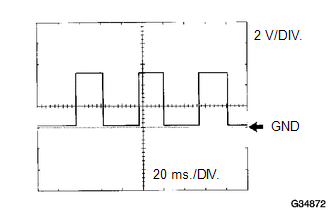

(a) Waveform 1

Reference

Reference

|

Terminal |

SPD - E1 |

|

Tool setting |

2 V/DIV., 20 ms./DIV. |

|

Vehicle condition |

Vehicle speed 20 km/h (12 mph) |

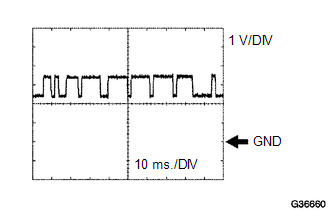

(b) Waveform 2

Reference

Reference

|

Terminal |

CAN+ - E1 |

|

Tool setting |

1 V/DIV., 10 ms./DIV. |

|

Vehicle condition |

Engine is stopped, ignition switch ON |

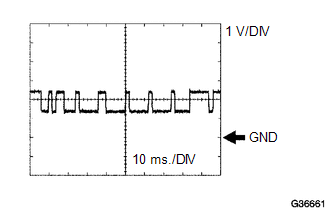

(c) Waveform 3

Reference

Reference

|

Terminal |

CAN- - E1 |

|

Tool setting |

1 V/DIV., 10 ms./DIV. |

|

Vehicle condition |

Engine is stopped, ignition switch ON |

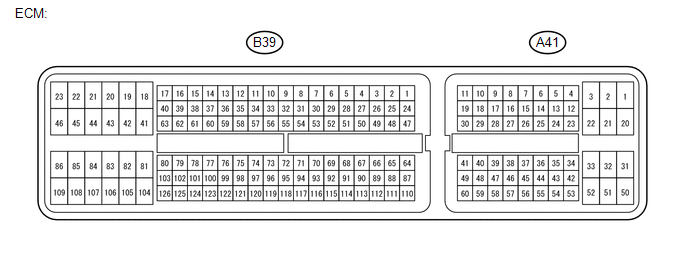

2. ECM

HINT:

Each ECM terminal standard voltage is shown in the table below.

In the table, first follow the information under "Condition". Look under "Terminal No. (Symbol)" for the terminals to be inspected. The standard voltage between the terminals is shown under "Specified Condition".

Use the illustration below as a reference for the ECM terminals.

|

Terminal No. (Symbol) |

Wiring Color |

Terminal Description |

Condition |

Specified Condition |

|---|---|---|---|---|

|

A41-25 (S) - B39-81 (E1) |

BE - W |

S shift position switch signal |

Ignition switch ON and shift lever in S |

11 to 14 V |

|

Ignition switch ON and shift lever in any position except S |

Below 1 V |

|||

|

A41-38 (SFTU) - B39-81 (E1) |

R - W |

Up shift switch signal |

Ignition switch ON and shift lever in S |

11 to 14 V |

|

Ignition switch ON and shift lever in "+" (Up shift) |

Below 1 V |

|||

|

A41-27 (SFTD) - B39-81 (E1) |

LG - W |

Down shift switch signal |

Ignition switch ON and shift lever in S |

11 to 14 V |

|

Ignition switch ON and shift lever in "-" (Down shift) |

Below 1 V |

Diagnosis System

Diagnosis System

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) When troubleshooting On-Board Diagnostic (OBD II) vehicles, the vehicle must

be connected to the OBD II scan tool (complying with SAE J1987). Various data outpu ...

Dtc Check / Clear

Dtc Check / Clear

DTC CHECK / CLEAR

NOTICE:

When the diagnosis system is changed from normal mode to check mode or vice versa,

all DTCs and freeze frame data recorded in normal mode are cleared. Before changing

m ...

Other materials about Toyota Venza:

Power Source Control ECU Malfunction (B2782)

DESCRIPTION

The power management control ECU controls the power supply to activate the steering

lock motor. This prevents the steering wheel from being locked while the vehicle

is moving.

DTC No.

DTC Detecting Condition

T ...

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the LH side and RH side.

The following procedure listed is for the LH side.

PROCEDURE

1. REMOVE FRONT WHEEL

2. REMOVE FRONT AXLE SHAFT NUT

3. SEPARATE FRONT SPEED SENS ...

Short in Driver Side Squib Circuit (B1800/51-B1803/51)

DESCRIPTION

The driver side squib circuit consists of the center airbag sensor assembly,

spiral cable and steering pad.

The center airbag sensor assembly uses this circuit to deploy the airbag when

deployment conditions are met.

These DTCs are stored wh ...

0.1634