Toyota Venza: Terminals Of Ecu

TERMINALS OF ECU

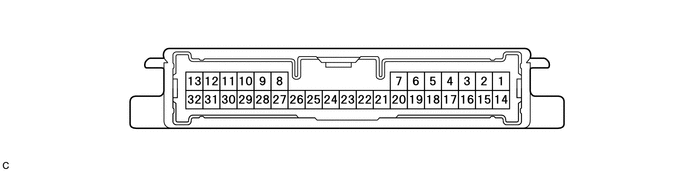

1. CHECK AWD CONTROL ECU

(a) Measure the voltage and resistance of the connector.

|

Terminal No. (Symbol) |

Terminal Description |

Condition |

Specified Condition |

|---|---|---|---|

|

14 (CANH) - 16 (CANL) |

CAN communication |

Ignition switch off |

54 to 69 Ω |

|

23 (GND) - Body ground |

Ground |

Always |

Below 1 Ω |

|

11 (IG1) - 23 (GND) |

Power source voltage |

Ignition switch ON |

10 to 14 V |

|

13 (SLC+) - 32 (SLC-) |

Electromagnetic solenoid signal |

D position, Idling |

Pulse generation (See waveform 1) |

|

9 (BSLC) - 23 (GND) |

Power source voltage |

Always |

10 to 14 V |

If the result is not as specified, the AWD control ECU may have a malfunction.

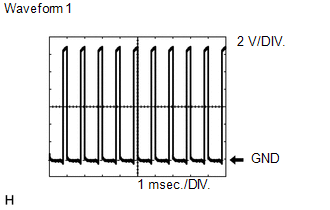

(b) Using an oscilloscope, check the waveform 1.

Waveform 1 (Reference)

Waveform 1 (Reference)

|

Terminal Name |

Content |

|---|---|

|

Tester Range |

2 V/DIV., 1 msec./DIV. |

|

Condition |

D position, Idling |

Test Mode Procedure

Test Mode Procedure

TEST MODE PROCEDURE

1. DESCRIPTION

HINT:

When using a chassis dynamometer, brake tester, etc. to perform a vehicle test,

activate test mode to avoid a "different tire diameter installed" ...

Diagnosis System

Diagnosis System

DIAGNOSIS SYSTEM

1. DESCRIPTION

Active torque control 4WD system data can be read in the Data Link Connector

3 (DLC3) of the vehicle. When the system seems to be malfunctioning, use the Techstream ...

Other materials about Toyota Venza:

Installation

INSTALLATION

PROCEDURE

1. INSTALL GENERATOR ASSEMBLY

(a) Install the generator with the 2 bolts.

Torque:

52 N·m {530 kgf·cm, 38 ft·lbf}

(b) Install the wire harness clamp bracke ...

Inspection

INSPECTION

PROCEDURE

1. INSPECT FRONT DIFFERENTIAL CASE

(a) Using SST, rotate the front differential side gear as shown in the

illustration.

SST: 09528-52010

09528-05030

Standard:

The front differential side gear does not lock wh ...

Diagnosis System

DIAGNOSIS SYSTEM

1. DESCRIPTION

Active torque control 4WD system data can be read in the Data Link Connector

3 (DLC3) of the vehicle. When the system seems to be malfunctioning, use the Techstream

to check for malfunctions and perform repairs. Therefore ...

0.1584