Toyota Venza: Knock Sensor

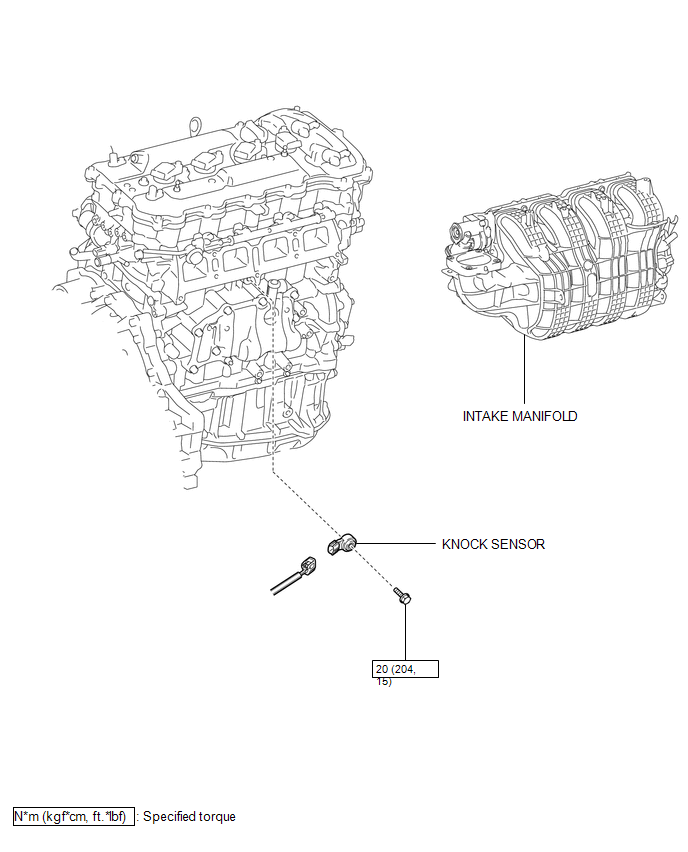

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE INTAKE MANIFOLD

(a) Remove the intake manifold (See page .gif) ).

).

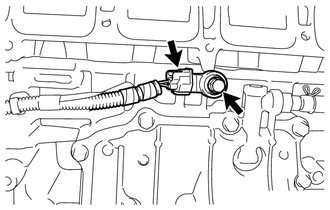

2. REMOVE KNOCK SENSOR

|

(a) Disconnect the sensor connector. |

|

(b) Remove the bolt and sensor.

Inspection

INSPECTION

PROCEDURE

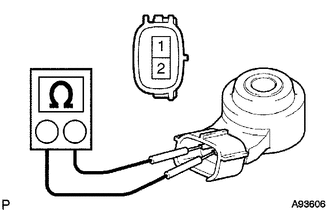

1. INSPECT KNOCK SENSOR

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the knock sensor. |

|

Installation

INSTALLATION

PROCEDURE

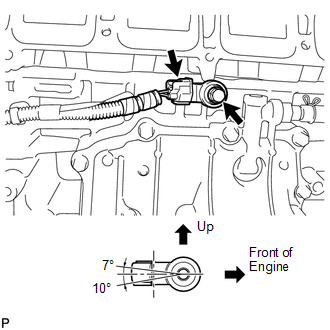

1. INSTALL KNOCK SENSOR

|

(a) Install the sensor with the bolt so that the sensor is angled as shown in the illustration. Torque: 20 N·m {204 kgf·cm, 15 ft·lbf} NOTICE: The acceptable installation angle of the sensor is between 7° upward and 10° downward from the horizontal position. HINT: Perform "Inspection After Repair" after replacing the knock control sensor

(See page |

|

(b) Connect the sensor connector.

2. INSTALL INTAKE MANIFOLD

(a) Install the intake manifold (See page .gif)

).

On-vehicle Inspection

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. PERFORM SPARK TEST

(a) Check for DTCs (See page ).

NOTICE:

If any DTC is output, perform troubleshooting procedures for that DTC.

(b) Remove the ignition coil ...

Mass Air Flow Meter

Mass Air Flow Meter

Components

COMPONENTS

ILLUSTRATION

On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

NOTICE:

Perform the mass air flow meter inspection according to the procedur ...

Other materials about Toyota Venza:

System Description

SYSTEM DESCRIPTION

1. SYSTEM DESCRIPTION

(a) The Electronic Controlled Automatic Transaxle (ECT) is an automatic transaxle

that has its shift timing electronically controlled by the Transmission Control

Module (TCM). The TCM detects electrical signals th ...

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE FRONT DRIVE SHAFT HOLE SNAP RING (for LH Side)

(a) Using a screwdriver, remove the front drive shaft hole snap ring.

2. REMOVE NO. 2 FRONT AXLE INBOARD JOINT BOOT CLA ...

Front Passenger Side Seat Belt Warning Light Malfunction

DESCRIPTION

The occupant classification ECU detects the state of the front seat inner belt

assembly RH and load sensor when the front passenger side seat is occupied with

the ignition switch ON. If the front passenger side seat belt is not fastened, the

...

0.1301