Toyota Venza: Terminals Of Ecu

TERMINALS OF ECU

1. CHECK POWER BACK DOOR ECU (POWER BACK DOOR MOTOR UNIT) (w/ POWER BACK DOOR SYSTEM)

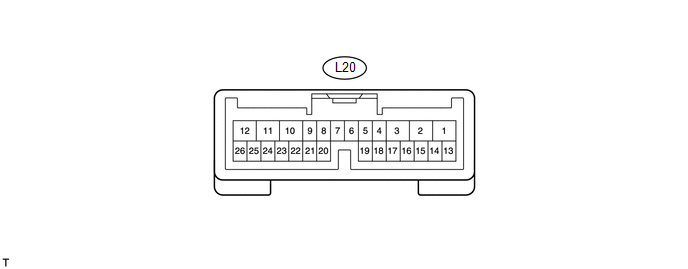

(a) Disconnect the L20 power back door ECU connector.

(b) Measure the voltage and resistance according to the value(s) in the table below.

|

Tester Connection |

Wiring Color |

Terminal Description |

Condition |

Specified Condition |

|---|---|---|---|---|

|

L20-12 (B) - Body ground |

LG - Body ground |

Battery power supply |

Always |

11 to 14 V |

|

L20-10 (ECUB) - Body ground |

P - Body ground |

Battery power supply |

Always |

11 to 14 V |

|

L20-8 (IG) - Body ground |

SB - Body ground |

IG power supply |

Ignition switch ON |

11 to 14 V |

|

L20-8 (IG) - Body ground |

SB - Body ground |

IG power supply |

Ignition switch off |

Below 1 V |

|

L20-11 (GND) - Body ground |

W-B - Body ground |

Ground |

Always |

Below 1 Ω |

If the result is not as specified, there may be a malfunction in the wire harness.

(c) Reconnect the L20 power back door ECU connector.

(d) Initialize the power back door system (See page

.gif) ).

).

(e) Measure the voltage according to the value(s) in the table below.

|

Tester Connection |

Wiring Color |

Terminal Description |

Condition |

Specified Condition |

|---|---|---|---|---|

|

L20-2 (DC+) - L20-1 (DC-) |

L - G |

Back door lock motor circuit |

Back door lock motor operating |

11 to 14 V |

|

L20-2 (DC+) - L20-1 (DC-) |

L - G |

Back door lock motor circuit |

Back door lock motor not operating |

Below 1 V |

|

L20-20 (FUL) - Body ground |

GR - Body ground |

Back door courtesy switch circuit |

Back door closed |

11 to 14 V |

|

L20-20 (FUL) - Body ground |

GR - Body ground |

Back door courtesy switch circuit |

Back door open |

Below 1 V |

|

L20-22 (HAF) - Body ground |

LG - Body ground |

Back door lock half-latch switch signal circuit |

Back door open → Back door closer operates → Back door closed |

Below 1 V → 11 to 14 V → Below 1 V |

|

L20-24 (POS) - Body ground |

P - Body ground |

Back door lock position switch signal circuit |

Back door open → Back door closer operates → Back door closed |

Below 1 V → 11 to 14 V → Below 1 V |

If the result is not as specified, the ECU may have a malfunction.

2. BACK DOOR CLOSER ECU (MULTIPLEX NETWORK DOOR ECU) (w/o POWER BACK DOOR SYSTEM)

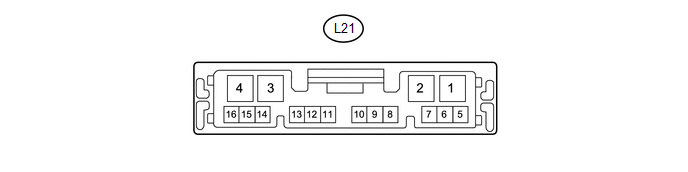

(a) Disconnect the L21 back door closer ECU connector.

(b) Measure the voltage and resistance according to the value(s) in the table below.

|

Tester Connection |

Wiring Color |

Terminal Description |

Condition |

Specified Condition |

|---|---|---|---|---|

|

L21-4 (B) - Body ground |

LG - Body ground |

Battery power supply |

Always |

11 to 14 V |

|

L21-16 (ECUB) - Body ground |

P - Body ground |

Battery power supply |

Always |

11 to 14 V |

|

L21-15 (IG) - Body ground |

SB - Body ground |

IG power supply |

Ignition switch ON |

11 to 14 V |

|

L21-15 (IG) - Body ground |

SB - Body ground |

IG power supply |

Ignition switch off |

Below 1 V |

|

L21-3 (GND) - Body ground |

W-B - Body ground |

Ground |

Always |

Below 1 Ω |

If the result is not as specified, there may be a malfunction in the wire harness.

(c) Reconnect the L21 back door closer ECU connector.

(d) Measure the voltage according to the value(s) in the table below.

|

Tester Connection |

Wiring Color |

Terminal Description |

Condition |

Specified Condition |

|---|---|---|---|---|

|

L21-2 (DC+) - L21-1 (DC-) |

L - G |

Back door lock motor circuit |

Back door lock motor operating |

11 to 14 V |

|

L21-2 (DC+) - L21-1 (DC-) |

L - G |

Back door lock motor circuit |

Back door lock motor not operating |

Below 1 V |

|

L21-6 (FUL) - Body ground |

GR - Body ground |

Back door courtesy switch circuit |

Back door closed |

11 to 14 V |

|

L21-6 (FUL) - Body ground |

GR - Body ground |

Back door courtesy switch circuit |

Back door open |

Below 1 V |

|

L21-5 (HAF) - Body ground |

LG - Body ground |

Back door lock half-latch switch signal circuit |

Back door open → Back door closer operates → Back door closed |

Below 1 V → 11 to 14 V → Below 1 V |

|

L21-7 (POS) - Body ground |

P - Body ground |

Back door lock position switch signal circuit |

Back door open → Back door closer operates → Back door closed |

Below 1 V → 11 to 14 V → Below 1 V |

If the result is not as specified, the ECU may have a malfunction.

3. CHECK MAIN BODY ECU (DRIVER SIDE JUNCTION BLOCK ASSEMBLY)

.png)

(a) Disconnect the D49 and 2F connectors.

(b) Measure the resistance according to the value(s) in the table below.

|

Tester Connection |

Wiring Color |

Terminal Description |

Condition |

Specified Condition |

|---|---|---|---|---|

|

D49-2 (BDSU) - Body ground |

GR - Body ground |

Back door opener switch signal circuit |

Back door opener switch on |

Below 1 Ω |

|

D49-2 (BDSU) - Body ground |

GR - Body ground |

Back door opener switch signal circuit |

Back door opener switch off |

10 kΩ or higher |

|

2F-16 (GND1) - Body ground |

W-B - Body ground |

Ground |

Always |

Below 1 Ω |

If the result is not as specified, there may be a malfunction on the wire harness side.

(c) Reconnect the D49 and 2F connectors.

(d) Measure the voltage according to the value(s) in the table below.

|

Tester Connection |

Wiring Color |

Terminal Description |

Condition |

Specified Condition |

|---|---|---|---|---|

|

D49-2 (BDSU) - Body ground |

GR - Body ground |

Back door opener switch signal circuit |

Back door opener switch off |

Pulse generation |

|

D49-2 (BDSU) - Body ground |

GR - Body ground |

Back door opener switch signal circuit |

Back door opener switch on |

Below 1 V |

If the result is not as specified, the ECU may have a malfunction.

Problem Symptoms Table

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are lis ...

Diagnosis System

Diagnosis System

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) The power back door ECU (power back door motor unit)*1 or back door closer

ECU (multiplex network door ECU)*2 controls the vehicle's back door closer system ...

Other materials about Toyota Venza:

4WD Control ECU Communication Stop Mode

DESCRIPTION

Detection Item

Symptom

Trouble Area

4WD Control ECU Communication Stop Mode

"Four Wheel Drive Control" is not displayed on the "CAN Bus

Check" screen ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL SPIRAL CABLE WITH SENSOR SUB-ASSEMBLY

NOTICE:

Do not replace the spiral cable with the battery connected and the ignition

switch on (IG).

Do not rotate the spiral cable with the battery connected and the ig ...

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" column ...

0.1672