Toyota Venza: Engine Coolant Temperature Receiver Gauge Malfunction

DESCRIPTION

In this circuit, the meter CPU receives engine coolant temperature signals from the ECM using the CAN communication system (CAN No. 1 Bus). The meter CPU displays engine coolant temperature that is calculated based on the data received from the ECM.

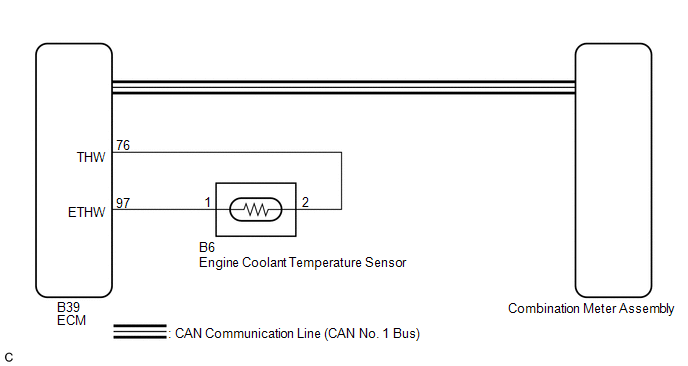

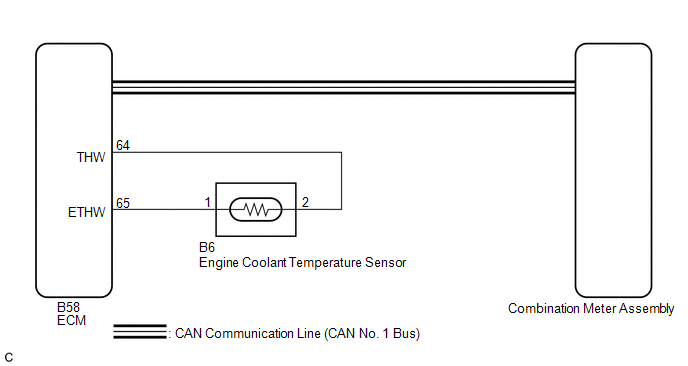

WIRING DIAGRAM

1. for 2GR-FE

2. for 1AR-FE

CAUTION / NOTICE / HINT

HINT:

If there is an open or short in the engine coolant temperature sensor circuit,

the ECM stores the DTCs. Refer to troubleshoot SFI System (See page

.gif) for 2GR-FE,

for 2GR-FE,

.gif) for 1AR-FE).

for 1AR-FE).

PROCEDURE

|

1. |

CHECK CAN COMMUNICATION SYSTEM |

(a) Check if a CAN communication DTC is output (See page

.gif) ).

).

|

Result |

Proceed to |

|---|---|

|

CAN communication DTC is not output. |

A |

|

CAN communication DTC is output. |

B |

| B | .gif) |

GO TO CAN COMMUNICATION SYSTEM |

|

|

2. |

PERFORM ACTIVE TEST USING TECHSTREAM (WATER TEMPERATURE METER OPERATION) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Combination Meter / Active Test.

(e) Check the operation by referring to the table below.

Combination Meter|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Water Temperature Meter Operation |

Engine coolant temperature receiver gauge |

Low, Normal, High |

Confirm that the vehicle is stopped with the engine idling |

OK:

Engine coolant temperature receiver gauge indication is normal.

| NG | .gif) |

REPLACE COMBINATION METER ASSEMBLY |

|

|

3. |

READ VALUE USING TECHSTREAM (COOLANT TEMPERATURE) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Combination Meter / Data List.

(e) Check the values by referring to the table below.

Combination Meter|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

Coolant Temperature |

Engine coolant temperature/Min.: 0°C (32°F), Max.: 127.5°C (261.5°F) |

After warming up: 80 to 100°C (176 to 212°F) |

|

OK:

Engine coolant temperature value displayed on the Techstream is almost the same as engine coolant temperature receiver gauge indication.

| NG | .gif) |

REPLACE COMBINATION METER ASSEMBLY |

|

|

4. |

READ VALUE USING TECHSTREAM (COOLANT TEMP) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine and ECT / Data List.

(e) Check the values by referring to the table below.

Engine and ECT (for 2GR-FE)|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

Engine Speed |

Vehicle speed/Min.: 0 rpm, Max.: 16383 rpm |

600 to 700 rpm (When idling) |

- |

|

Coolant Temp |

Engine coolant temperature/Min.: -40°C (-40°F), Max: 215°C (419°F) |

80 to 100°C (176 to 212°F): After warming up |

|

|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

Engine Speed |

Vehicle speed/Min.: 0 rpm, Max.: 16383 rpm |

600 to 700 rpm (When idling) |

- |

|

Coolant Temp |

Engine coolant temperature/Min.: -40°C (-40°F), Max: 140°C (284°F) |

80 to 100°C (176 to 212°F): After warming up |

|

OK:

Engine coolant temperature value displayed on the Techstream is almost the same as the Techstream indication (Body Electrical / Combination Meter / Data List).

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (for 2GR-FE) |

B |

|

NG (for 1AR-FE) |

C |

| A | .gif) |

REPLACE COMBINATION METER ASSEMBLY |

| B | .gif) |

REPLACE ECM (for 2GR-FE) |

| C | .gif) |

REPLACE ECM (for 1AR-FE) |

Tachometer Malfunction

Tachometer Malfunction

DESCRIPTION

In this circuit, the meter CPU receives engine speed signals from the ECM using

the CAN communication system (CAN No. 1 Bus). The meter CPU displays the engine

speed calculated based ...

Fuel Receiver Gauge Malfunction

Fuel Receiver Gauge Malfunction

DESCRIPTION

The meter CPU uses the fuel sender gauge assembly to determine the level

of the fuel in the fuel tank. The resistance of the fuel sender gauge will

vary between approximate ...

Other materials about Toyota Venza:

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE FRONT TRANSAXLE CASE OIL SEAL

(a) Using SST, remove the front transaxle case oil seal from the transaxle

housing.

SST: 09308-00010

2. REMOVE TRANSAXLE CASE OIL ...

Front Crankshaft Oil Seal

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT WHEEL RH

2. REMOVE NO. 1 ENGINE UNDER COVER

3. SEPARATE FRONT FENDER LINER RH

4. REMOVE FRONT FENDER APRON SEAL RH

5. REMOVE V-RIBBED BELT

6. REMOVE CRANKSHAFT ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL ROOF HEADLINING ASSEMBLY (w/o Sliding Roof)

(a) Pull the roof headlining assembly into the vehicle through the back

door.

NOTICE:

Do not damage the roof headlining assembly or body interior.

...

0.1748

.gif)