Toyota Venza: Slide Sensor Malfunction (B2650)

DESCRIPTION

When the position control ECU and switch assembly does not receive a sensor signal despite forward or backward movement of seat by power seat motor operation, this DTC is output.

|

DTC Code |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

B2650 |

The forward and backward lock detection position of the sensor is the same. |

|

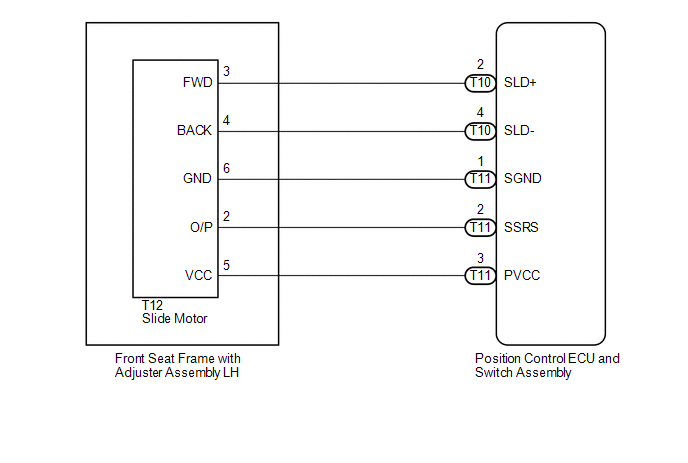

WIRING DIAGRAM

PROCEDURE

|

1. |

CHECK FOR DTC |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Driver Seat / Trouble Codes.

(e) Clear the DTC (See page .gif) ).

).

(f) Recheck for DTC B2650.

|

Result |

Proceed to |

|---|---|

|

DTC B2650 is output |

A |

|

DTC B2650 is not output |

B |

| B | .gif) |

USE SIMULATION METHOD TO CHECK |

|

|

2. |

PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Enter the following menus: Body Electrical / Driver Seat / Active Test.

(b) Perform the Active Test according to the display on the Techstream.

Driver Seat|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Seat Slide Operation |

Seat sliding operation |

OFF/Front/Rear |

- |

OK:

Motor operates normally.

| NG | .gif) |

GO TO STEP 5 |

|

|

3. |

CHECK HARNESS AND CONNECTOR (POSITION CONTROL ECU AND SWITCH ASSEMBLY - SLIDE MOTOR) |

(a) Disconnect the T11 the position control ECU and switch assembly connector.

(b) Disconnect the T12 the slide motor (front seat frame with adjuster assembly LH) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

T11-3 (PVCC) - T12-5 (VCC) |

Always |

Below 1 Ω |

|

T11-2 (SSRS) - T12-2 (O/P) |

Always |

Below 1 Ω |

|

T11-1 (SGND) - T12-6 (GND) |

Always |

Below 1 Ω |

|

T11-3 (PVCC) - Body ground |

Always |

10 kΩ or higher |

|

T11-2 (SSRS) - Body ground |

Always |

10 kΩ or higher |

|

T11-1 (SGND) - Body ground |

Always |

10 kΩ or higher |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

CHECK POSITION CONTROL ECU AND SWITCH ASSEMBLY (SLIDE MOTOR CIRCUIT) |

(a) Reconnect the T11 the position control ECU and switch assembly connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

T12-5 (VCC) - T12-6 (GND) |

Slide switch on |

5.5 to 6.5 V |

| OK | .gif) |

REPLACE FRONT SEAT FRAME WITH ADJUSTER ASSEMBLY LH |

| NG | .gif) |

REPLACE POSITION CONTROL ECU AND SWITCH ASSEMBLY |

|

5. |

INSPECT FRONT SEAT FRAME WITH ADJUSTER ASSEMBLY LH |

(a) Disconnect the T12 the slide motor (front seat frame with adjuster assembly LH) connector.

|

(b) Check if the seat frame moves smoothly when the battery is connected to the slide motor connector terminals. OK:

|

|

| NG | .gif) |

REPLACE FRONT SEAT FRAME WITH ADJUSTER ASSEMBLY LH |

|

|

6. |

CHECK HARNESS AND CONNECTOR (POSITION CONTROL ECU AND SWITCH ASSEMBLY - SLIDE MOTOR) |

(a) Disconnect the T10 the position control ECU and switch assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

T10-2 (SLD+) - T12-3 (FWD) |

Always |

Below 1 Ω |

|

T10-4 (SLD-) - T12-4 (BACK) |

Always |

Below 1 Ω |

|

T10-2 (SLD+) - Body ground |

Always |

10 kΩ or higher |

|

T10-4 (SLD-) - Body ground |

Always |

10 kΩ or higher |

| OK | .gif) |

REPLACE POSITION CONTROL ECU AND SWITCH ASSEMBLY |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Diagnostic Trouble Code Chart

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

If a trouble code is displayed during the DTC check, inspect the trouble areas

listed for that code. For details of the code, refer to the ''See page'' ...

Short in Sensor with Motor Power Supply Circuit (B2658)

Short in Sensor with Motor Power Supply Circuit (B2658)

DESCRIPTION

This DTC is stored if sensor voltage does not reach the designated voltage while

the slide motor is operating.

DTC Code

DTC Detection Condition

Trouble ...

Other materials about Toyota Venza:

Lost Communication with ECM / PCM "A" (U0100-U0142,U0155)

DESCRIPTION

These DTCs are stored when the clearance warning ECU assembly cannot receive

and recognize several signals via the CAN communication system.

DTC No.

DTC Detection Condition

Trouble Area

U0100

...

Light Sensor Circuit Malfunction (B1244)

DESCRIPTION

The automatic light control sensor detects ambient light, converts it into an

electrical signal, and outputs it to the main body ECU (driver side junction block

assembly). The main body ECU (driver side junction block assembly) turns on or off ...

Removal

REMOVAL

PROCEDURE

1. REMOVE REAR SEAT HEADREST ASSEMBLY

(a) Press the headrest support button and pull up the headrest as shown

in the illustration to remove it.

2. REMOVE REAR SEAT INNER TRACK ...

0.131

.gif)