Toyota Venza: Sensor (Motor) Failure (B2341,B2344)

DESCRIPTION

When the sliding roof ECU (sliding roof drive gear sub-assembly) detects a motor malfunction and the sliding roof operation is stopped, DTC B2341 is output.

When the sliding roof ECU (sliding roof drive gear sub-assembly) detects a gear malfunction and the sliding roof operation is stopped, DTC B2344 is output.

|

DTC Code |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

B2341 |

Sensor (motor) failure (When the ECU enters fail-safe mode due to a problem with the motor) |

|

|

B2344 |

Position failure (When the ECU enters fail-safe mode due to a problem with the gear position) |

|

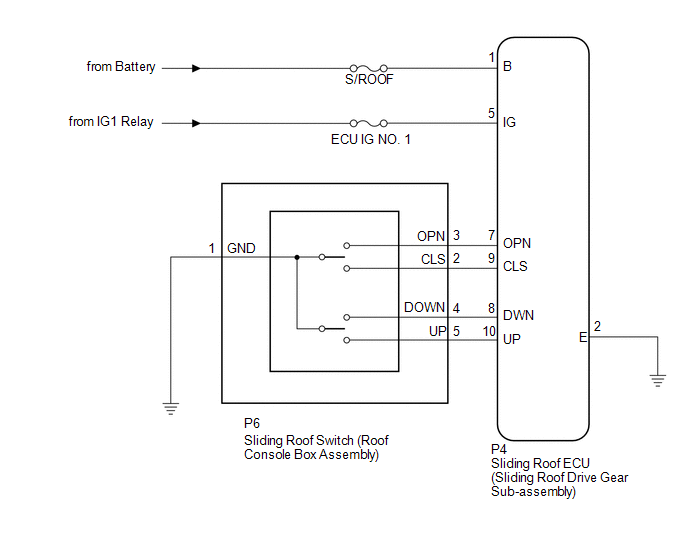

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- Inspect the fuses for circuits related to this system before performing the following inspection procedure.

- When the sliding roof ECU (sliding roof drive gear sub-assembly) is

replaced or removed and reinstalled, it requires initialization (See page

.gif) ).

).

PROCEDURE

|

1. |

CHECK SLIDING ROOF OPERATION |

(a) Check the sliding roof auto operation (See page

.gif) ).

).

OK:

Auto operation operates normally.

| NG | .gif) |

GO TO STEP 3 |

|

|

2. |

CHECK DTC OUTPUT |

(a) Clear the DTC (See page .gif) ).

).

(b) Recheck for DTCs.

OK:

DTC B2341 or B2344 is not output.

| OK | .gif) |

USE SIMULATION METHOD TO CHECK |

| NG | .gif) |

REPLACE SLIDING ROOF ECU (SLIDING ROOF DRIVE GEAR SUB-ASSEMBLY) |

|

3. |

INITIALIZE SLIDING ROOF ECU (SLIDING ROOF DRIVE GEAR SUB-ASSEMBLY) |

(a) Check that the sliding roof ECU (sliding roof drive gear sub-assembly) can

be initialized (See page .gif) ).

).

OK:

Sliding roof ECU (sliding roof drive gear sub-assembly) can be initialized.

| NG | .gif) |

GO TO STEP 5 |

|

|

4. |

CHECK DTC OUTPUT |

(a) Clear the DTC (See page .gif) ).

).

(b) Recheck for DTCs.

OK:

DTC B2341 or B2344 is not output.

| OK | .gif) |

END |

| NG | .gif) |

REPLACE SLIDING ROOF ECU (SLIDING ROOF DRIVE GEAR SUB-ASSEMBLY) |

|

5. |

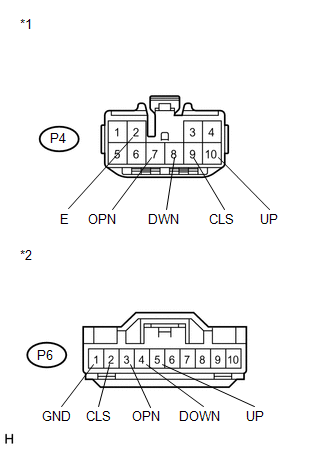

CHECK HARNESS AND CONNECTOR (SLIDING ROOF ECU - SLIDING ROOF SWITCH) |

|

(a) Disconnect the P6 switch connector. |

|

(b) Disconnect the P4 ECU connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

P4-9 (CLS) - P6-2 (CLS) |

Always |

Below 1 Ω |

|

P4-9 (CLS) - Body ground |

Always |

10 kΩ or higher |

|

P4-7 (OPN) - P6-3 (OPN) |

Always |

Below 1 Ω |

|

P4-7 (OPN) - Body ground |

Always |

10 kΩ or higher |

|

P4-8 (DWN) - P6-4 (DOWN) |

Always |

Below 1 Ω |

|

P4-8 (DWN) - Body ground |

Always |

10 kΩ or higher |

|

P4-10 (UP) - P6-5 (UP) |

Always |

Below 1 Ω |

|

P4-10 (UP) - Body ground |

Always |

10 kΩ or higher |

|

P6-1 (GND) - Body ground |

Always |

Below 1 Ω |

|

P4-2 (E) - Body ground |

Always |

Below 1 Ω |

|

*1 |

Front view of wire harness connector (to Sliding Roof ECU (Sliding Roof Drive Gear Sub-assembly)) |

|

*2 |

Front view of wire harness connector (to Sliding Roof Switch (Roof Console Box Assembly)) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

6. |

INSPECT SLIDING ROOF SWITCH (ROOF CONSOLE BOX ASSEMBLY) |

|

(a) Remove the sliding roof switch (roof console box assembly) (See page

|

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

P6-4 (DOWN) - P6-1 (GND) |

TILT DOWN switch is pressed |

Below 1 Ω |

|

P6-4 (DOWN) - P6-1 (GND) |

TILT DOWN switch is not pressed |

10 kΩ or higher |

|

P6-5 (UP) - P6-1 (GND) |

TILT UP switch is pressed |

Below 1 Ω |

|

P6-5 (UP) - P6-1 (GND) |

TILT UP switch is not pressed |

10 kΩ or higher |

|

P6-2 (CLS) - P6-1 (GND) |

SLIDE CLOSE switch is pressed |

Below 1 Ω |

|

P6-2 (CLS) - P6-1 (GND) |

SLIDE CLOSE switch is not pressed |

10 kΩ or higher |

|

P6-3 (OPN) - P6-1 (GND) |

SLIDE OPEN switch is pressed |

Below 1 Ω |

|

P6-3 (OPN) - P6-1 (GND) |

SLIDE OPEN switch is not pressed |

10 kΩ or higher |

|

*1 |

Component without harness connected (Sliding Roof Switch (Roof Console Box Assembly)) |

| OK | .gif) |

REPLACE SLIDING ROOF ECU (SLIDING ROOF DRIVE GEAR SUB-ASSEMBLY) |

| NG | .gif) |

REPLACE SLIDING ROOF SWITCH (ROOF CONSOLE BOX ASSEMBLY) |

Switch Failure (B2342)

Switch Failure (B2342)

DESCRIPTION

This DTC is output when the sliding roof ECU (sliding roof drive gear sub-assembly)

detects that the sliding roof switch is stuck for 30 seconds or more.

DTC Code

...

Sliding Roof does not Move by Operating Sliding Roof Control Switch

Sliding Roof does not Move by Operating Sliding Roof Control Switch

DESCRIPTION

The sliding roof ECU (sliding roof drive gear sub-assembly) receives switch slide

and tilt signals and drives its built-in motor.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

...

Other materials about Toyota Venza:

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the cable from the negative (-)

battery terminal to disable the SRS system (See page

).

NOTICE:

When disconnecting the cable, s ...

Inspection

INSPECTION

PROCEDURE

1. INSPECT TRANSMISSION OIL CLEANER MAGNET

(a) Use the removed transmission oil cleaner magnets to collect any steel

chips. Examine the chips and particles in the automatic transaxle oil pan

sub-assembly and on the tr ...

Gauges and meters

►Vehicles with smart key system

The following gauges, meters and display illuminate when the “ENGINE START STOP”

switch is in IGNITION ON mode.

►Vehicles without smart key system

The following gauges, meters and displays illuminate when ...

0.1196

.gif)

.png)