Toyota Venza: Removal

REMOVAL

PROCEDURE

1. DISCHARGE FUEL SYSTEM PRESSURE

HINT:

See page .gif)

2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

3. REMOVE WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

(a) Remove the windshield wiper motor and link assembly (See page

.gif) ).

).

4. REMOVE OUTER COWL TOP PANEL

.gif)

5. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

.gif)

6. REMOVE NO. 1 VACUUM SWITCHING VALVE ASSEMBLY

.gif)

7. REMOVE AIR CLEANER CAP SUB-ASSEMBLY

.gif)

8. REMOVE FUEL TUBE SUB-ASSEMBLY

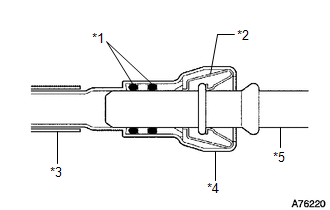

Text in Illustration

Text in Illustration

|

*1 |

No. 2 Fuel Pipe Clamp |

|

*2 |

Retainer |

|

*3 |

Fuel Hose Clamp |

|

*4 |

Fuel Tube Connector |

.png) |

Turn |

.png) |

Pull |

NOTICE:

Do not forcibly bend, kink or twist the fuel tube.

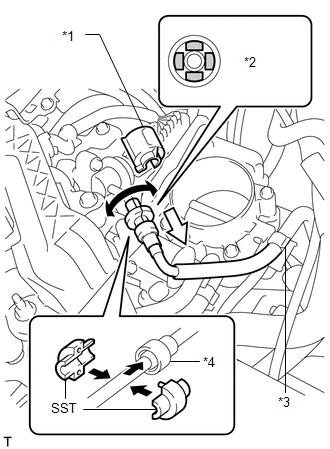

(a) Remove the No. 2 fuel pipe clamp.

(b) Wipe off any dirt on the fuel tube connector.

(c) Hold the fuel tube connector, and then install SST.

SST: 09268-21011

(d) Turn SST to align the retainer inside the fuel tube connector with the chamfered part of SST.

(e) Insert SST into the fuel tube and hold it. Then push the fuel tube connector toward SST.

(f) Mount the retainer of the fuel tube connector onto the chamfered part of SST.

|

(g) Slide SST and the fuel tube connector together toward the fuel tube until they make a "click" sound, and then disconnect the fuel tube. Text in Illustration

NOTICE:

|

|

(h) Remove the No. 1 fuel pipe clamp.

(i) Pinch the tube connector, and then pull the tube connector off of the pipe.

.png) Text in Illustration

Text in Illustration

|

*1 |

Fuel Pipe |

|

*2 |

Fuel Tube Connector |

|

*3 |

Nylon Tube |

|

*4 |

O-ring |

|

*5 |

Retainer |

.png) |

Pinch |

.png) |

Pull |

NOTICE:

- Check for foreign matter on the fuel tube around the fuel tube connector. Clean it if necessary. Foreign matter can affect the ability of the O-ring to seal the fuel tube connector and fuel pipe.

- Do not use any tools to separate the fuel tube connector and fuel pipe.

- Do not forcibly bend, kink or twist the nylon tube.

- Keep the connector and pipe free from foreign matter.

- If the fuel tube connector and fuel pipe are stuck, push and pull to release them.

- Put the fuel tube connector and fuel pipe in plastic bags to prevent damage and contamination.

(j) Remove the fuel tube sub-assembly from the fuel hose clamp.

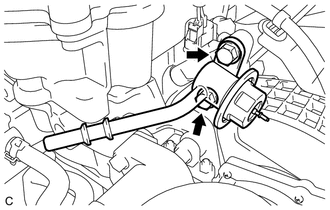

9. REMOVE FUEL PRESSURE PULSATION DAMPER ASSEMBLY

|

(a) Remove the 2 bolts and fuel pressure pulsation damper assembly. |

|

(b) Remove the O-ring from the fuel pressure pulsation damper assembly.

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL FUEL PRESSURE PULSATION DAMPER ASSEMBLY

(a) Apply a light coat of gasoline or spindle oil to a new O-ring.

Text in Illustration

* ...

Other materials about Toyota Venza:

System Description

SYSTEM DESCRIPTION

1. GENERAL

(a) To assist the driver with parking the vehicle by displaying an image of the

area behind the vehicle, this system has a rear television camera assembly mounted

on the back door. The system displays the image on the naviga ...

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page ).

2. REMOVE FRONT WHEEL RH

3. REMOVE NO. 1 ENGINE UNDER COVER

4. ...

Turn Signal Flasher Assembly

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT TURN SIGNAL FLASHER ASSEMBLY

(a) Disconnect the D34 turn signal flasher assembly connector.

(b) Measure the vo ...

0.1704