Toyota Venza: Pressure Control Solenoid "G" Electrical (Shift Solenoid Valve SL4) (P2810)

DESCRIPTION

Changing from 1st to 6th is performed by the TCM turning shift solenoid valves

SL1, SL2, SL3, SL4 and SL on and off. If an open or short circuit occurs in any

of the shift solenoid valves, the TCM controls the remaining normal shift solenoid

valves to allow the vehicle to be operated (See page

.gif) )

)

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

P2810 |

The TCM checks for an open or short in the shift solenoid valve SL4 circuit while driving and shifting gears. (1-trip detection logic)

|

|

MONITOR DESCRIPTION

The TCM commands gear shifts by turning the shift solenoid valves on or off. When there is an open or short circuit in any shift solenoid valve circuit, the TCM detects the problem and illuminates the MIL and stores the DTC. And the TCM performs the fail-safe function and turns the other normal shift solenoid valves on or off (In case of an open or short circuit, the TCM stops sending current to the circuit.)

(See page .gif) ).

).

MONITOR STRATEGY

|

Related DTCs |

P2810: Shift solenoid valve SL4/Range check |

|

Required sensors/Components |

Shift solenoid valve SL4 |

|

Frequency of operation |

Continuous |

|

Duration |

1 sec. |

|

MIL operation |

Immediate |

|

Sequence of operation |

None |

TYPICAL ENABLING CONDITIONS

All|

The monitor will run whenever the following DTCs are not present |

None |

|

Ignition switch |

ON |

|

Starter |

OFF |

|

Battery voltage |

12 V or more |

|

Battery voltage |

10 V or more and less than 12 V |

|

Target current |

Less than 0.75 A |

|

Battery voltage |

8 V or more |

|

Target current |

0.25 A or more |

TYPICAL MALFUNCTION THRESHOLDS

Condition (A) and (B)|

Output duty cycle |

100% or more |

|

Output duty cycle |

0% or less |

COMPONENT OPERATING RANGE

|

Output duty cycle |

More than 3% and less than 100% |

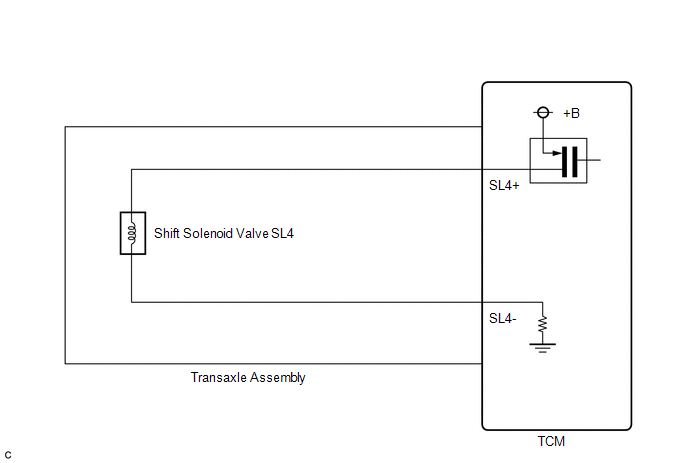

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Perform the universal trip to clear permanent DTCs (See page

.gif) ).

).

PROCEDURE

|

1. |

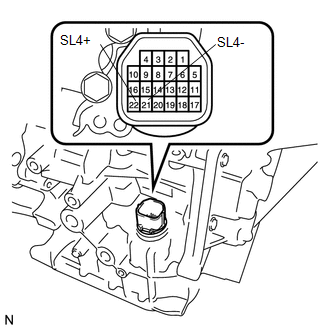

INSPECT TRANSMISSION WIRE (SL4) |

|

(a) Remove the TCM from the transaxle. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

22 (SL4+) - 21 (SL4-) |

20°C (68°F) |

5.0 to 5.6 Ω |

|

22 (SL4+) - Body ground |

Always |

10 kΩ or higher |

|

21 (SL4-) - Body ground |

Always |

10 kΩ or higher |

|

22 (SL4+) - All other terminals except 21 (SL4-) |

Always |

10 kΩ or higher |

|

21 (SL4-) - All other terminals except 22 (SL4+) |

Always |

10 kΩ or higher |

| OK | .gif) |

REPLACE TCM |

|

|

2. |

INSPECT SHIFT SOLENOID VALVE SL4 |

|

(a) Remove shift solenoid valve SL4. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 - 2 |

20°C (68°F) |

5.0 to 5.6 Ω |

|

*1 |

Shift Solenoid Valve SL4 |

(c) Connect a battery positive (+) lead with a 21 W bulb to terminal 2 and a negative (-) lead to terminal 1 of the solenoid valve connector. Then check that the valve moves and makes an operating sound.

OK:

Valve moves and makes an operating sound.

| OK | .gif) |

REPLACE TRANSMISSION WIRE |

| NG | .gif) |

REPLACE SHIFT SOLENOID VALVE SL4 |

Pressure Control Solenoid "G" Performance (Shift Solenoid Valve SL4) (P2808)

Pressure Control Solenoid "G" Performance (Shift Solenoid Valve SL4) (P2808)

DESCRIPTION

The TCM uses the vehicle speed signal and signals from the transmission speed

sensors (NC, NT) to detect the actual gear (1st, 2nd, 3rd, 4th, 5th or 6th gear).

Then the TCM compares th ...

Lost Communication with ECM / PCM "A" (U0100)

Lost Communication with ECM / PCM "A" (U0100)

DESCRIPTION

The engine control unit communicates with the TCM using the Controller Area Network

(CAN).

If there is a problem in this communication, the TCM sets a DTC.

DTC No.

...

Other materials about Toyota Venza:

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuator and other items to be read without removing any parts. This non-intrusive

inspection can be very useful beca ...

Engine Hood Courtesy Switch

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT SECURITY COURTESY SWITCH (HOOD LOCK ASSEMBLY)

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

...

Back Door Entry Lock Function does not Operate

DESCRIPTION

If the back door entry lock function does not operate but the back door open

function operates, the communication between the vehicle and key is normal. As a

faulty part, the entry lock switch circuit (from the back door opener switch assembly ...

0.1425

.gif)

.png)