Toyota Venza: Parking Brake Switch Circuit

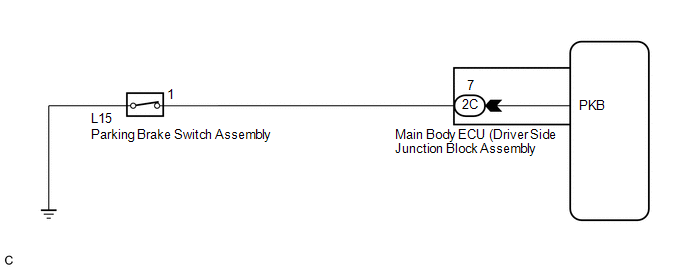

DESCRIPTION

The main body ECU (driver side junction block assembly) detects the condition of the parking brake switch.

WIRING DIAGRAM

PROCEDURE

|

1. |

READ VALUE USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Main Body / Data List.

(e) Read the display on the Techstream.

Main Body|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

Parking Brake SW |

Parking brake SW signal/ON or OFF |

ON: Parking brake switch on OFF: Parking brake switch off |

- |

OK:

Normal conditions listed above are displayed.

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

|

|

2. |

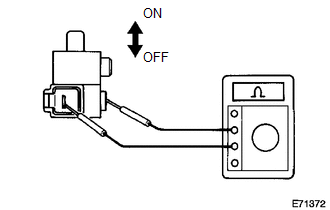

INSPECT PARKING BRAKE SWITCH ASSEMBLY |

|

(a) Remove the parking brake switch assembly (See page

|

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 - Switch body |

Shaft pushed in (OFF) |

10 kΩ or higher |

|

1 - Switch body |

Shaft not pushed in (ON) |

Below 1 Ω |

| NG | .gif) |

REPLACE PARKING BRAKE SWITCH ASSEMBLY |

|

|

3. |

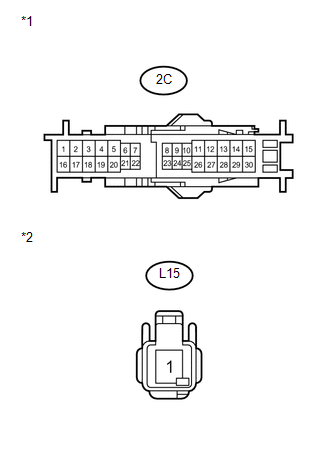

CHECK HARNESS AND CONNECTOR (SWITCH - MAIN BODY ECU (DRIVER SIDE JUNCTION BLOCK ASSEMBLY)) |

|

(a) Disconnect the 2C main body ECU (driver side junction block assembly) connector. |

|

(b) Disconnect the L15 parking brake switch assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

2C-7 - L15-1 |

Always |

Below 1 Ω |

|

2C-7 - Body ground |

Always |

10 kΩ or higher |

|

*1 |

Front view of wire harness connector: (to Main Body ECU (Driver Side Junction Block Assembly)) |

|

*2 |

Front view of wire harness connector (to Parking Brake Switch Assembly) |

| OK | .gif) |

REPLACE MAIN BODY ECU (DRIVER SIDE JUNCTION BLOCK ASSEMBLY) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Door Mirror Foot Light Circuit

Door Mirror Foot Light Circuit

DESCRIPTION

The main body ECU (driver side junction block assembly) controls the door mirror

foot lights.

WIRING DIAGRAM

1. w/o Seat Position Memory:

2. w/ Seat Position Memory:

PROCEDURE

...

Taillight Relay Circuit

Taillight Relay Circuit

DESCRIPTION

The main body ECU (driver side junction block assembly) controls the operation

of the TAIL relay.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits rel ...

Other materials about Toyota Venza:

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

Use the table below to help determine the cause of problem symptoms. If multiple

suspected areas are listed, the potential causes of the symptoms are listed in order

of probability in the "Suspected Area" column of the tab ...

Lost Communication with Front Airbag Sensor LH (B1617/84,B1618/84)

DESCRIPTION

The front airbag sensor LH circuit consists of the center airbag sensor assembly

and front airbag sensor LH.

The front airbag sensor LH detects impacts to the vehicle and sends signals to

the center airbag sensor assembly to determine if the ...

Removal

REMOVAL

PROCEDURE

1. REMOVE REAR SEAT HEADREST ASSEMBLY

(a) Press the headrest support button and pull up the rear seat headrest

assembly as shown in the illustration.

2. REMOVE REAR SEAT CENTER ...

0.3975

.gif)

.gif) ).

).