Toyota Venza: Open in Outside Luggage Compartment Electrical Key Antenna Circuit (B27A8)

DESCRIPTION

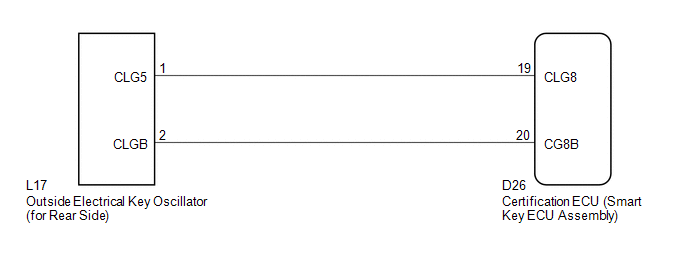

The certification ECU (smart key ECU assembly) generates a request signal and sends it to the outside electrical key oscillator (for rear side). To detect the key near the driver door, the outside electrical key oscillator (for rear side) creates a detection area towards the area approximately 1.0 m (3.28 ft.) from the back door.

DTC B27A8 is detected by the certification ECU (smart key ECU assembly) when an open circuit occurs between the certification ECU (smart key ECU assembly) and outside electrical key oscillator (for rear side) terminals (between CLG8 and CLG5, or CG8B and CLGB).

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

B27A8 |

Open circuit detected between the certification ECU (smart key ECU assembly and outside electrical key oscillator (for rear side) terminals (between CLG8 and CLG5, or CG8B and CLGB). |

|

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

The smart key system (for entry function) uses a multiplex communication system

(LIN communication system) and CAN communication system. Inspect the communication

function by following How to Proceed with Troubleshooting (See page

.gif) ). Troubleshoot the smart key system (for entry

). Troubleshoot the smart key system (for entry

function) after confirming that the communication system is functioning properly.

PROCEDURE

|

1. |

CHECK CONNECTOR CONNECTION CONDITION |

(a) Turn the engine switch off.

(b) Check that the connectors are properly connected to the certification ECU (smart key ECU assembly) and the outside electrical key oscillator (for rear side).

OK:

Connectors are properly connected.

| NG | .gif) |

CONNECT CONNECTORS PROPERLY |

|

|

2. |

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU - OUTSIDE ELECTRICAL KEY OSCILLATOR) |

(a) Disconnect the certification ECU (smart key ECU assembly) connector.

|

(b) Disconnect the outside electrical key oscillator (for rear side) connector. |

|

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D26-19 (CLG8) - L17-1 (CLG5) |

Always |

Below 1 Ω |

|

D26-20 (CG8B) - L17-2 (CLGB) |

Always |

Below 1 Ω |

|

D26-19 (CLG8) - Body ground |

Always |

10 kΩ or higher |

|

D26-20 (CG8B) - Body ground |

Always |

10 kΩ or higher |

|

L17-1 (CLG5) - Body ground |

Always |

10 kΩ or higher |

|

L17-2 (CLGB) - Body ground |

Always |

10 kΩ or higher |

|

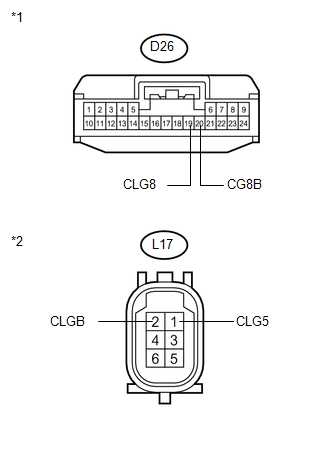

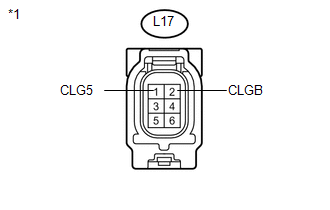

*1 |

Front view of wire harness connector (to Certification ECU (Smart Key ECU Assembly)) |

|

*2 |

Front view of wire harness connector (to Outside Electrical Key Oscillator (for Rear Side)) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

INSPECT OUTSIDE ELECTRICAL KEY OSCILLATOR |

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG | .gif) |

REPLACE OUTSIDE ELECTRICAL KEY OSCILLATOR |

|

|

4. |

REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

(a) Replace the certification ECU (smart key ECU assembly) (See page

.gif) ).

).

|

|

5. |

CHECK DTC OUTPUT |

(a) Clear the DTCs (See page .gif) ).

).

(b) Recheck for DTCs.

OK:

DTC B27A8 is not output.

| OK | .gif) |

END (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) WAS DEFECTIVE) |

| NG | .gif) |

REPLACE OUTSIDE ELECTRICAL KEY OSCILLATOR |

Diagnostic Trouble Code Chart

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

HINT:

If a trouble code is stored during the DTC check, inspect the trouble areas listed

for that code. For details of the code, refer to the "See page" bel ...

Open in Rear Floor Electrical Key Oscillator Circuit (B27A6)

Open in Rear Floor Electrical Key Oscillator Circuit (B27A6)

DESCRIPTION

The certification ECU (smart key ECU assembly) generates a request signal and

sends it to the indoor electrical key oscillator (for center floor). To detect the

key inside the cabin, ...

Other materials about Toyota Venza:

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

HINT:

If a trouble code is displayed during the DTC check, inspect the trouble areas

listed for that code. For details of the code, refer to the "See page" below.

Power Steering System

DTC Code

...

Customize Parameters

CUSTOMIZE PARAMETERS

HINT:

The following items can be customized.

NOTICE:

After confirming whether the items requested by the customer are applicable

or not for customization, perform customizing operations.

Be sure to record the current se ...

LVL Terminal Circuit

DESCRIPTION

By connecting terminals LVL and CG of the DLC3, the headlight leveling

ECU assembly initializes the height control sensor signal.

WIRING DIAGRAM

PROCEDURE

1.

CHECK HARNESS AND CONNECTOR (DLC3 - HEADLIGH ...

0.1218

.gif)