Toyota Venza: On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. CHECK RADIATOR CAP SUB-ASSEMBLY

(a) Measure the valve opening pressure.

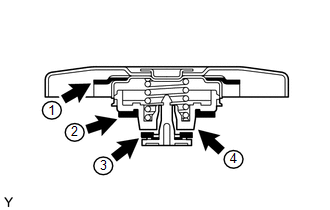

(1) If there are water stains or foreign matter on rubber packings 1, 2 or 3, clean the part(s) with water and finger scouring.

(2) Check that rubber packings 1, 2 and 3 are not deformed, cracked or swollen.

(3) Check that 3 and 4 are not stuck together.

(4) Apply engine coolant to rubber packings 2 and 3 before using the radiator cap tester.

|

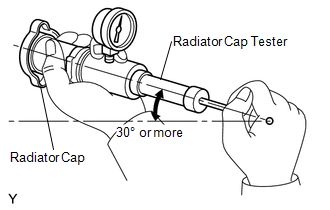

(5) When using the cap tester, tilt it to 30° or more above level. |

|

(6) Pump the cap tester several times, and check the maximum pressure*.

Pump speed:

1 pump per second

*: Even if the cap cannot maintain the maximum pressure, it is not a defect.

Judgment Criterion:

|

Item |

Specified Condition |

|---|---|

|

Standard value (for brand-new cap) |

94 to 122 kPa (1.0 to 1.2 kgf/cm2, 13.6 to 17 psi) |

|

Minimum standard value (for used cap) |

79 kPa (0.8 kgf/cm2, 11.4 psi) |

If the measured maximum pressure is less than the minimum standard value, replace the radiator cap sub-assembly.

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL RADIATOR ASSEMBLY

(a) Install the fan assembly with motor to the radiator with the 2 guides

at the bottom and 3 snap fits on the top.

Text in Ill ...

Other materials about Toyota Venza:

Theft Deterrent System Communication Line High Fixation (B279A)

DESCRIPTION

If the communication line (EFIO-IMI) to the transponder key ECU assembly is stuck

high output (e.g. shorted to +B), the ECM stores this DTC.

DTC No.

DTC Detection Condition

Trouble Area

B279A

...

Vehicle Speed Signal Error (Test Mode DTC) (C2191/91)

DESCRIPTION

The tire pressure warning ECU receives a vehicle speed signal from the combination

meter. This DTC is stored upon entering signal check mode (test mode), and cleared

when a vehicle speed signal of 20 km/h (12 mph) is detected for 3 seconds or ...

USB Media Malfunction (B1585)

DESCRIPTION

This DTC is stored when a malfunction occurs in a connected device.

DTC No.

DTC Detection Condition

Trouble Area

B1585

When any of the following conditions is met:

A non m ...

0.1542