Toyota Venza: On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

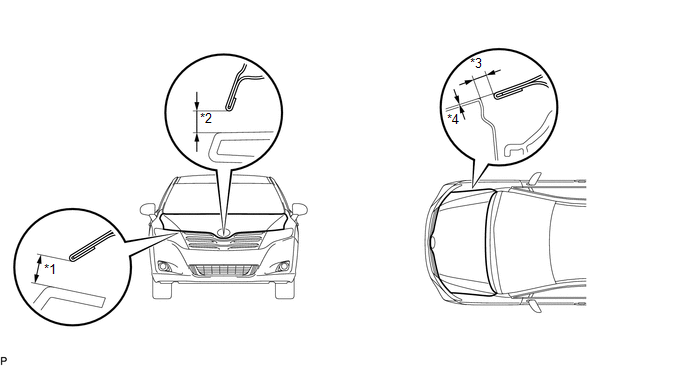

1. INSPECT HOOD SUB-ASSEMBLY

(a) Check that the clearance measurements of areas *1 through *4 are within each standard range.

Standard Clearance

Standard Clearance

|

Area |

Measurement |

Area |

Measurement |

|---|---|---|---|

|

*1 |

6.9 to 9.9 mm (0.272 to 0.390 in.) |

*3 |

2.8 to 5.8 mm (0.110 to 0.228 in.) |

|

*2 |

7.6 to 10.6 mm (0.299 to 0.417 in.) |

*4 |

-1.5 to 1.5 mm (-0.0591 to 0.0591 in.) |

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE HOOD TO RADIATOR SUPPORT SEAL

(a) Using a clip remover, disengage the 10 clips and remove the hood

to radiator support seal.

...

Adjustment

Adjustment

ADJUSTMENT

CAUTION / NOTICE / HINT

HINT:

Centering bolts are used to mount the hood hinge and hood lock. The

hood and hood lock cannot be adjusted with the centering bolts installed. ...

Other materials about Toyota Venza:

Driver Side Solar Sensor Short Circuit (B14A2)

DESCRIPTION

The solar sensor is installed on the upper side of the instrument panel. It detects

sunlight to control air conditioning AUTO mode. The output voltage from the solar

sensor varies in accordance with the amount of sunlight. When the amount of ...

System Diagram

SYSTEM DIAGRAM

Communication Table

Transmitting ECU

Receiving ECU

Signal

Communication Method

Air Conditioning Control Assembly

Air Conditioning Amplifier Assembly

Rear windo ...

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful bec ...

0.1161