Toyota Venza: On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. CHECK FOR FUEL PUMP OPERATION AND INSPECT FOR FUEL LEAK

(a) Check fuel pump operation.

(1) Connect the Techstream to the DLC3.

(2) Turn the ignition switch to ON and turn the Techstream on.

NOTICE:

Do not start the engine.

(3) Enter the following menus: Powertrain / Engine / Active Test / Control the Fuel Pump / Speed.

(4) Check for pressure in the fuel inlet tube from the fuel line. Check that the sound of fuel flowing from the fuel tank can be heard. If no sound can be heard, check the integration relay, fuel pump, ECM and wiring connectors.

(b) Inspect for fuel leaks.

(1) Check that there are no fuel leaks from the fuel system after doing any maintenance or repairs. If there is a fuel leak, repair or replace parts as necessary.

(c) Turn the ignition switch off.

(d) Disconnect the Techstream from the DLC3.

2. CHECK FUEL PRESSURE

(a) Discharge fuel system pressure.

HINT:

(See page .gif) ).

).

(b) Using a voltmeter, measure the battery voltage.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Positive (+) terminal - Negative (-) terminal |

Ignition switch off |

11 to 14 V |

(c) Disconnect the cable from the negative (-) battery terminal.

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

|

(d) Remove the No. 1 fuel pipe clamp from the fuel tube connector. |

|

(e) Disconnect the fuel hose from the fuel main tube (See page

.gif) ).

).

|

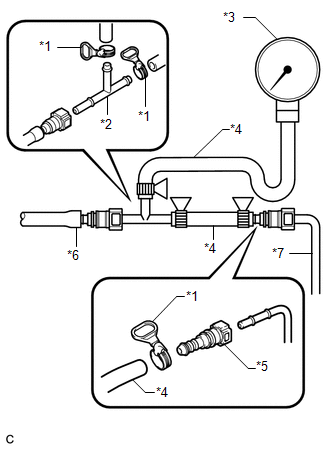

(f) Install SST (pressure gauge) as shown in the illustration. Text in Illustration

SST: 09268-31014 09268-41500 09268-41700 95336-08070 SST: 09268-45014 09268-41200 09268-41220 09268-41250 |

|

(g) Wipe up any gasoline.

(h) Connect the cable to the negative (-) battery terminal.

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

(i) Connect the Techstream to the DLC3.

(j) Enter the following menus: Powertrain / Engine / Active Test / Control the Fuel Pump / Speed.

(k) Measure the fuel pressure.

Standard fuel pressure:

304 to 343 kPa (3.1 to 3.5 kgf/cm2, 44 to 50 psi)

- If the fuel pressure is greater than the standard value, replace the fuel pressure regulator.

- If the fuel pressure is less than the standard value, check the fuel hoses and connections, fuel pump, fuel filter and fuel pressure regulator.

(l) Disconnect the Techstream from the DLC3.

(m) Start the engine.

(n) Measure the fuel pressure at idle.

Standard fuel pressure:

304 to 343 kPa (3.1 to 3.5 kgf/cm2, 44 to 50 psi)

(o) Stop the engine.

(p) Check that the fuel pressure remains as specified for 5 minutes after the engine stops.

Standard fuel pressure:

147 kPa (1.5 kgf/cm2, 21 psi) or more

If the fuel pressure is not as specified, check the fuel pump, pressure regulator and/or fuel injectors.

(q) After checking the fuel pressure, disconnect the cable from the negative (-) battery terminal and carefully remove SST to prevent gasoline from spraying.

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

(r) Reconnect the fuel tube to the main fuel tube (fuel tube connector).

(s) Install the No. 1 fuel pipe clamp to the fuel tube connector.

(t) Inspect for fuel leaks (See step 1).

Parts Location

Parts Location

PARTS LOCATION

ILLUSTRATION

...

System Diagram

System Diagram

SYSTEM DIAGRAM

...

Other materials about Toyota Venza:

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL COOLER DRYER

(a) Using pliers, install a new cooler dryer to the modulator.

(b) Apply sufficient compressor oil to the O-ring and fitting surfaces

of t ...

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT REAR COMBINATION LIGHT ASSEMBLY

(a) Disconnect the connector from the rear combination light assembly.

(b) Measure the voltage according to the value(s) in ...

Illumination for Panel Switch does not Come on with Tail Switch ON

PROCEDURE

1.

CHECK VEHICLE SIGNAL (OPERATION CHECK)

(a) Enter the "Vehicle Signal Check Mode" screen. Refer to Check Vehicle Signal

in Operation Check (See page ).

(b) Check that the display changes between ON ...

0.1688

.png)