Toyota Venza: Inspection

INSPECTION

PROCEDURE

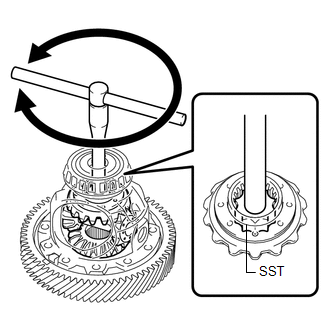

1. INSPECT FRONT DIFFERENTIAL CASE

|

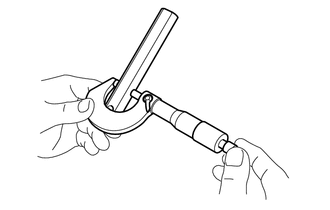

(a) Using SST, rotate the front differential side gear as shown in the illustration. SST: 09528-52010 09528-05030 Standard: The front differential side gear does not lock when rotated in either direction.

|

|

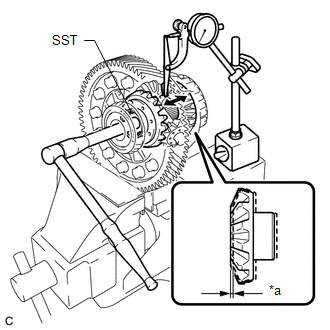

2. INSPECT FRONT DIFFERENTIAL SIDE GEAR THRUST AMOUNT

(a) Secure the front differential case in a vise between aluminum plates.

NOTICE:

Do not overtighten the vise.

|

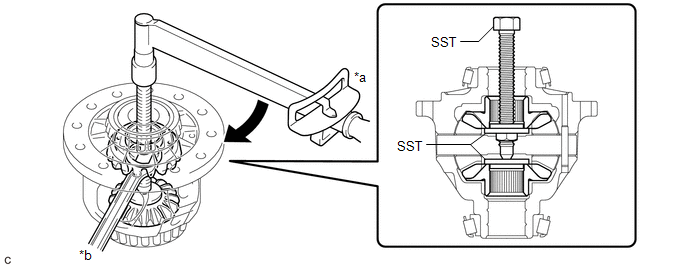

(b) Using SST and a dial indicator, measure the front differential side gear thrust amount. Text in Illustration

SST: 09528-52010 09528-05030 Front Differential Side Gear Thrust Amount: 0.08 mm (0.00315 in.) or less HINT:

If the result is not as specified, replace the 2 front differential side gears, 2 front differential pinions and 2 conical springs. |

|

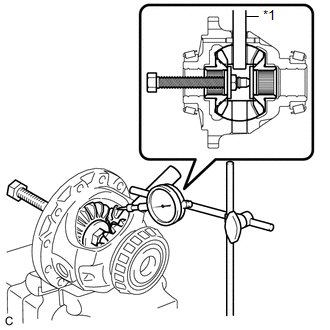

3. INSPECT FRONT DIFFERENTIAL PINION BACKLASH

(a) Install SST as shown in the illustration and tighten it.

Text in Illustration

Text in Illustration

|

*a |

Turn |

*b |

Hold |

SST: 09528-52010

09528-05010

09953-05010

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

(b) Secure the front differential case in a vise between aluminum plates.

NOTICE:

Do not overtighten the vise.

|

(c) Install the front No. 1 differential pinion shaft to the front differential pinion as shown in the illustration. Text in Illustration

|

|

(d) Using a dial indicator, measure the front differential pinion backlash.

Standard Backlash:

0.15 mm (0.00591 in.) or less

HINT:

Select front No. 1 differential side gear thrust washers of the same thickness for both the right and left side.

If the backlash is not as specified, replace the front No. 1 differential side gear thrust washers with washers of a different thickness. Use the table below to select front No. 1 differential side gear thrust washers which will ensure that the backlash is within the specification.

Front No. 1 Differential Side Gear Thrust Washer Thickness:|

Part No. |

Thickness (mm (in.)) |

|---|---|

|

41361-06010 |

1.50 (0.0591) |

|

41361-06020 |

1.55 (0.0610) |

|

41361-06030 |

1.60 (0.0630) |

|

41361-06040 |

1.65 (0.0650) |

|

41361-06050 |

1.70 (0.0669) |

|

41361-06060 |

1.75 (0.0689) |

|

41361-06070 |

1.80 (0.0709) |

|

41361-06080 |

1.85 (0.0728) |

|

41361-06090 |

1.90 (0.0748) |

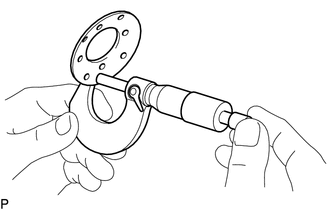

4. INSPECT FRONT DIFFERENTIAL PINION THRUST WASHER

|

(a) Using a micrometer, measure the thickness of the front differential pinion thrust washer. Minimum Thickness: 0.54 mm (0.0213 in.) HINT: Measure the most worn portion of the front differential pinion thrust washer. If the thickness is less than the minimum, replace the front differential pinion thrust washer. |

|

5. INSPECT FRONT NO. 1 DIFFERENTIAL PINION SHAFT

|

(a) Using a micrometer, measure the outer diameter of the front No. 1 differential pinion shaft. Minimum Outer Diameter: 20.499 mm (0.807 in.) HINT: Measure the most worn portion of the front No. 1 differential pinion shaft. If the outer diameter is less than the minimum, replace the front No. 1 differential pinion shaft. |

|

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE FRONT TRANSAXLE CASE OIL SEAL

(a) Using SST, remove the front transaxle case oil seal from the transaxle

housing.

SST: 09308-00010

...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL FRONT DIFFERENTIAL CASE REAR TAPERED ROLLER BEARING

(a) Using SST and a press, install a new front differential case rear

tapered roller bearing (inne ...

Other materials about Toyota Venza:

Disposal

DISPOSAL

CAUTION / NOTICE / HINT

CAUTION:

Before performing pre-disposal deployment of any SRS component, review and closely

follow all applicable environmental and hazardous material regulations. Pre-disposal

deployment may be considered hazardous mate ...

Fog Light Assembly

Components

COMPONENTS

ILLUSTRATION

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE FOG LIGHT BULB

(a) Turn the fog light bulb in the direction indicated by the arrow shown

in the illustration and remove it.

NOTICE:

Do not touch th ...

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE REAR WHEEL

2. SEPARATE NO. 3 PARKING BRAKE CABLE ASSEMBLY

(a) Remov ...

0.134