Toyota Venza: Inspection

INSPECTION

PROCEDURE

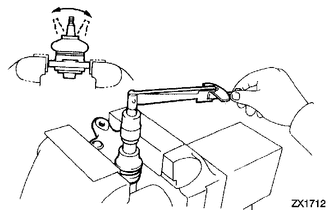

1. INSPECT FRONT LOWER BALL JOINT

|

(a) Inspect the turning torque of the ball joint. (1) Secure the front lower ball joint in a vise using aluminum plates. (2) Install the nut to the front lower ball joint stud. (3) Using a torque wrench, turn the nut continuously at a rate of 3 to 5 seconds per turn and take the torque reading on the 5th turn. Turning torque: 0.7 to 4.5 N*m (7 to 46 kgf*cm, 6.2 to 40 in.*lbf) If the turning torque is not within the specified range, replace the front lower ball joint with a new one. |

|

(b) Inspect the dust cover.

(1) Check that the dust cover is not cracked and that there is no grease on it.

Components

Components

COMPONENTS

ILLUSTRATION

...

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the LH side and RH side.

The following procedure listed is for the LH side.

PROCEDURE

1. REMOVE FRONT WHEEL

2. ...

Other materials about Toyota Venza:

Interior Light Power Source Circuit

DESCRIPTION

The main body ECU (driver side junction block assembly) controls operation of

the DOME CUT relay in order to supply power to the interior lights.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this ...

XM Tuner Malfunction (B15BA)

DESCRIPTION

These DTCs are stored when a malfunction occurs in the stereo component tuner

assembly.

DTC No.

DTC Detection Condition

Trouble Area

B15BA

When either of the following conditions is m ...

Differential Oil

Replacement

REPLACEMENT

CAUTION / NOTICE / HINT

HINT:

Stop the vehicle on a level surface.

PROCEDURE

1. DRAIN DIFFERENTIAL OIL

(a) Using a 10 mm hexagon wrench, remove the rear differential carrier

cover plug and gasket.

...

0.1364