Toyota Venza: Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the LH side and RH side.

- The following procedure listed is for the LH side.

PROCEDURE

1. REMOVE FRONT WHEEL

2. REMOVE FRONT AXLE SHAFT NUT

.gif)

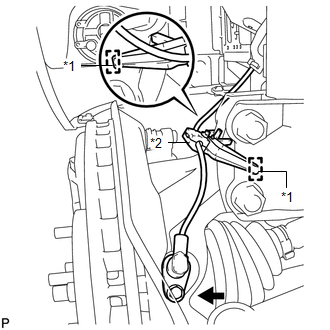

3. SEPARATE FRONT SPEED SENSOR

|

(a) Remove the bolt and resin clamp, and separate the front speed sensor. Text in Illustration

NOTICE:

|

|

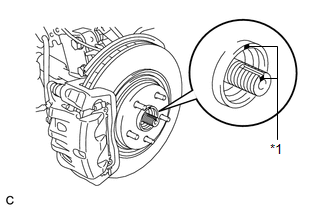

4. SEPARATE FRONT DRIVE SHAFT ASSEMBLY

|

(a) Put matchmarks on the front drive shaft assembly and front axle hub sub-assembly. Text in Illustration

|

|

|

(b) Using a plastic hammer, separate the front drive shaft assembly from the front axle assembly. NOTICE: Loosen the staked part of the front axle hub nut completely, otherwise the threads of the drive shaft may be damaged. |

|

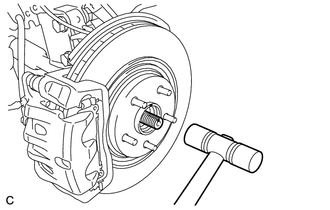

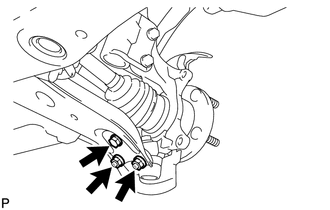

5. SEPARATE FRONT DISC BRAKE CALIPER ASSEMBLY

|

(a) Remove the 2 bolts and separate the front disc brake caliper assembly. NOTICE: Use wire or an equivalent tool to keep the brake caliper from hanging down by the flexible hose. |

|

6. REMOVE FRONT DISC

.gif)

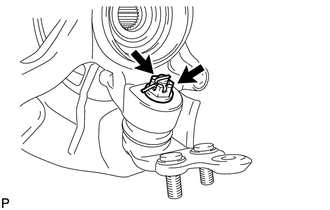

7. SEPARATE TIE ROD ASSEMBLY

.gif)

8. SEPARATE FRONT LOWER SUSPENSION ARM

|

(a) Remove the bolt, 2 nuts, and separate the front lower suspension arm from the lower ball joint. |

|

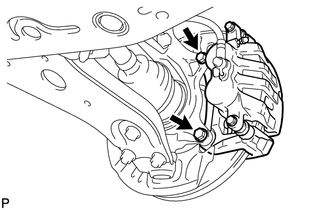

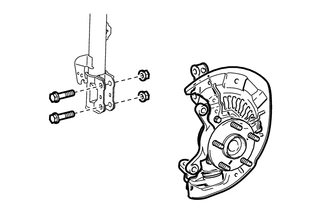

9. REMOVE FRONT AXLE ASSEMBLY

|

(a) Remove the 2 bolts, 2 nuts and front axle assembly. NOTICE: When removing the nuts, keep the bolts from rotating. |

|

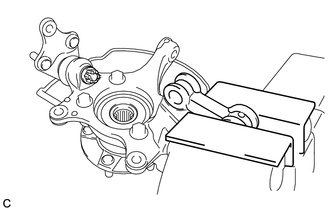

10. REMOVE FRONT LOWER BALL JOINT

|

(a) Secure the front axle assembly in a vise using aluminum plates. NOTICE: When using a vise, do not overtighten it. |

|

|

(b) Remove the cotter pin and nut. |

|

|

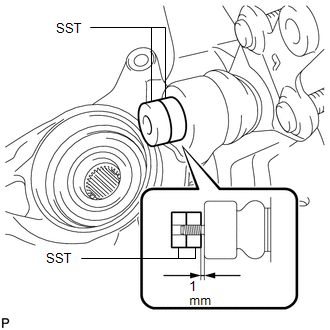

(c) Install SST to the front lower ball joint as shown in the illustration. SST: 09960-20010 09961-02050 09961-02050 NOTICE: Check that the clearance measurement between SST and the front axle assembly is 1 mm (0.0394 in.). |

|

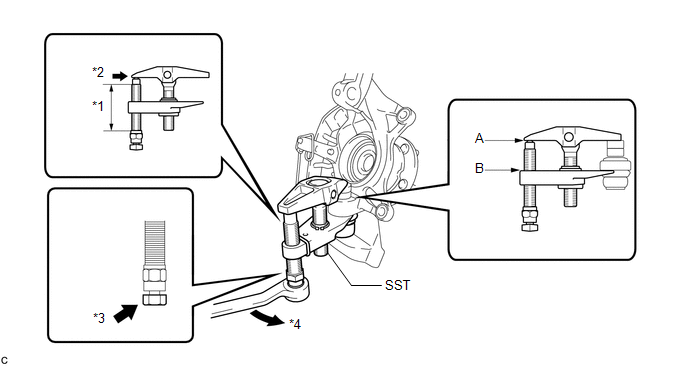

(d) Using SST, remove the front lower ball joint from the front axle assembly as shown in the illustration.

Text in Illustration

Text in Illustration

|

*1 |

Apply grease |

*3 |

Place the wrench here |

|

*2 |

Apply grease |

*4 |

Turn |

SST: 09960-20010

09961-02010

09961-02050

09961-02050

CAUTION:

Apply grease to the threads and end of the SST bolt.

NOTICE:

- Install SST so that A and B are parallel.

- Be sure to place a wrench on the part indicated in the illustration.

- Do not damage the front lower ball joint dust cover, or steering knuckle.

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT FRONT LOWER BALL JOINT

(a) Inspect the turning torque of the ball joint.

(1) Secure the front lower ball joint in a vise using aluminum plates.

(2) ...

Installation

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the LH side and RH side.

The following procedure listed is for the LH side.

PROCEDURE

1. INSTALL FRONT LOWE ...

Other materials about Toyota Venza:

Installation

INSTALLATION

PROCEDURE

1. INSTALL NO. 3 ANTENNA CORD SUB-ASSEMBLY

(a) Pass the washer hose through the No. 3 antenna cord sub-assembly.

(b) Pass the No. 3 antenna cord sub-assembly with washer hose through

the vehicle body as shown in the il ...

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" ...

System Description

SYSTEM DESCRIPTION

1. GENERAL

The rear window defogger wires are attached to the inside of the rear window

and defog the window surface quickly by pressing the rear window defogger switch

on the air conditioning control assembly. The indicator light is i ...

0.1142