Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT GENERATOR CLUTCH PULLEY

|

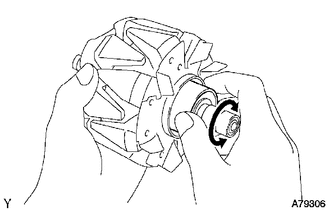

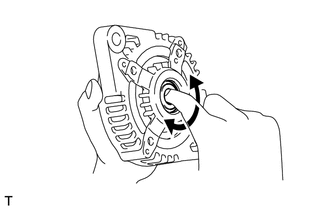

(a) Hold the generator rotor using SST, and turn the clutch pulley clockwise to check that the outer ring locks. SST: 09820-63021 Text in Illustration

If the result is not as specified, replace the clutch pulley. |

|

2. INSPECT GENERATOR DRIVE END FRAME BEARING

|

(a) Check that the bearing is not rough or worn. OK: The bearing rotates smoothly. If the bearing does not rotate smoothly, replace the bearing. |

|

3. INSPECT GENERATOR BRUSH HOLDER ASSEMBLY

|

(a) Using a vernier caliper, measure the length of the exposed brushes. Text in Illustration

Standard exposed brush length: 9.5 to 11.5 mm (0.375 to 0.452 in.) Minimum exposed brush length: 4.5 mm (0.178 in.) If the exposed brush length is less than the minimum, replace the brush holder assembly. |

|

4. INSPECT GENERATOR ROTOR ASSEMBLY

|

(a) Check that the generator rotor bearing is not rough or worn. If necessary, replace the generator rotor assembly. |

|

|

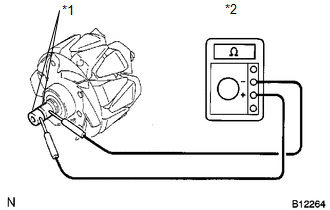

(b) Check the generator rotor for an open circuit. Text in Illustration

(1) Using an ohmmeter, measure the resistance between the slip rings. Standard Resistance:

If the result is not as specified, replace the generator rotor assembly. |

|

||||||||||||||

|

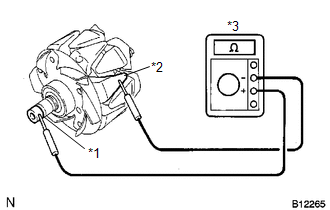

(c) Check the rotor for a short to ground. Text in Illustration

(1) Using an ohmmeter, measure the resistance between the slip ring and rotor. Standard Resistance:

If the result is not as specified, replace the generator rotor assembly. |

|

|

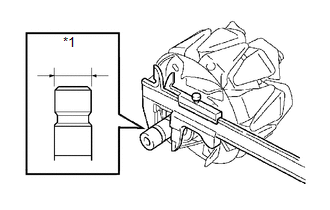

(d) Using a vernier caliper, measure the slip ring diameter. Text in Illustration

Standard diameter: 14.2 to 14.4 mm (0.560 to 0.566 in.) Minimum diameter: 14.0 mm (0.552 in.) If the diameter is less than the minimum, replace the generator rotor assembly. |

|

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE GENERATOR REAR END COVER

(a) Remove the 3 nuts and generator rear end cover.

2. REMOVE TERMINAL INSULATOR

...

Replacement

Replacement

REPLACEMENT

PROCEDURE

1. REPLACE GENERATOR DRIVE END FRAME BEARING

(a) Remove the 4 screws and bearing retainer from the drive end frame.

...

Other materials about Toyota Venza:

Seat heaters

1. For driver’s seat

2. For front passenger’s seat

3. On

The indicator light comes on.

4. Adjusts the seat temperature

The further you turn the dial upward, the warmer the seat becomes.

- The seat heaters can be used when

►Vehicles wit ...

Precaution

PRECAUTION

1. INITIALIZATION

NOTICE:

Perform the Registration (VIN registration) when replacing the ECM (See page

).

HINT:

Reset memory or initialization cannot be completed by only disconnecting and

reconnecting the cable of the negative (-) battery ...

High Mounted Stop Light Assembly

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE CENTER STOP LIGHT ASSEMBLY

(a) Using a short screwdriver, remove the 2 screws.

(b) Disconnect the connector and remov ...

0.1339

.png)

.png)