Toyota Venza: Replacement

REPLACEMENT

PROCEDURE

1. REPLACE GENERATOR DRIVE END FRAME BEARING

|

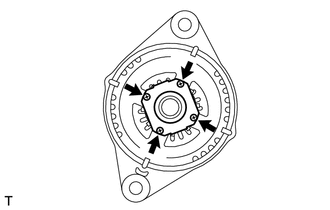

(a) Remove the 4 screws and bearing retainer from the drive end frame. |

|

|

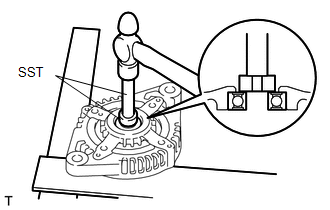

(b) Using SST and a hammer, tap out the drive end frame bearing from the drive end frame. SST: 09950-60010 09951-00250 SST: 09950-70010 09951-07100 |

|

|

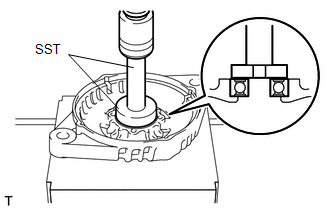

(c) Using SST and a press, press in a new generator drive end frame bearing. SST: 09950-60010 09951-00470 SST: 09950-70010 09951-07100 |

|

|

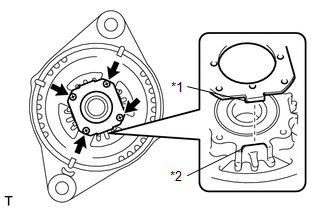

(d) Fit the tabs on the retainer plate into the cutouts on the drive end frame to install the retainer plate. Text in Illustration

|

|

(e) Install the 4 screws.

Torque:

2.3 N·m {23 kgf·cm, 20 in·lbf}

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT GENERATOR CLUTCH PULLEY

(a) Hold the generator rotor using SST, and turn the clutch pulley clockwise

to check that the outer ring locks.

SST: 09820 ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL GENERATOR ASSEMBLY

(a) Install the wire harness clamp with the bolt.

Torque:

8.4 N·m {86 kgf·cm, 74 in·lbf}

...

Other materials about Toyota Venza:

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful bec ...

Diagnosis System

DIAGNOSIS SYSTEM

1. DESCRIPTION

Active torque control 4WD system data can be read in the Data Link Connector

3 (DLC3) of the vehicle. When the system seems to be malfunctioning, use the Techstream

to check for malfunctions and perform repairs. Therefore ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL REAR NO. 1 SUSPENSION ARM ASSEMBLY LH

(a) Temporarily install the rear No. 1 suspension arm assembly LH to

the rear suspension member with the bolt and the nut.

Text in Illustration

*1

...

0.143