Toyota Venza: Initialization

INITIALIZATION

NOTICE:

Make sure that the front passenger seat is not occupied before performing the operation.

HINT:

Perform zero point calibration and sensitivity check if any of the following conditions occur:

- The occupant classification ECU is replaced.

- Accessories (seatback tray and seat cover, etc.) are installed.

- The front passenger seat is removed from the vehicle.

- The passenger airbag ON/OFF indicator ("OFF") comes on when the front passenger seat is not occupied.

- An occupant classification sensor collision detection DTC is output due to an accident or a collision.

1. ZERO POINT CALIBRATION

(a) Zero point calibration procedure

HINT:

Make sure that the zero point calibration has finished normally, and then perform sensitivity check.

(1) Check that all of the following conditions are met:

- The vehicle is parked on a level surface.

- No objects are placed on the front passenger seat.

- The front passenger seat belt buckle switch is off.

(2) Adjust the seat position according to the table below.

|

Adjustment Item |

Position |

|---|---|

|

Slide Direction |

Rearmost position |

|

Reclining Angle |

Upright position |

|

Headrest Height |

Lowest position |

(3) Turn the ignition switch off.

(4) Connect the Techstream to the DLC3.

(5) Turn the ignition switch to ON and turn the Techstream on.

(6) Enter the following menus: Body Electrical / Occupant Detection / Utility / Zero Point Calibration.

(7) Perform zero point calibration by following the prompts on the Techstream screen.

HINT:

- Refer to the Techstream operator's manual for further details.

- If zero point calibration does not complete, replace the front seat frame with adjuster assembly RH

OK:

"Zero Point Calibration is complete." is displayed.

2. SENSITIVITY CHECK

(a) Sensitivity check procedure

(1) Turn the ignition switch off.

(2) Connect the Techstream to the DLC3.

(3) Turn the ignition switch to ON and turn the Techstream on.

(4) Enter the following menus: Body Electrical / Occupant Detection / Utility / Sensitivity Check.

(5) Perform sensitivity check by following the prompts on the Techstream screen.

HINT:

Refer to the Techstream operator's manual for further details.

(6) Confirm that the initial sensor reading is within the specified range.

Standard:

-3.2 to 3.2 kg (-7.0 to 7.0 lb)

(7) Place a 30 kg (66.1 lb) weight (eg. a 30 kg (66.1 lb) of lead mass) onto the front passenger seat.

NOTICE:

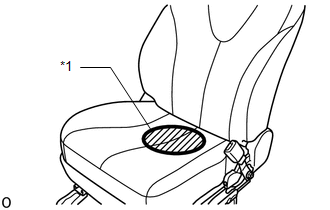

- Do not allow the weight to come into contact with the seatback when placing it on the seat cushion.

- Place the weight in the area shown in the illustration.

|

*1 |

Weight Position |

(8) Confirm that sensitivity is within the specified range.

Standard:

27 to 33 kg (59.5 to 72.8 lb)

HINT:

- When performing sensitivity check, use a solid metal weight (the check result may not appear properly if a liquid weight made from liquid is used).

- If sensitivity deviates from the specified range, retighten the bolts of the front passenger seat without deforming the seat rail. After performing this procedure, if sensitivity is not within the specified range, replace the front seat frame with adjuster assembly RH.

System Description

System Description

SYSTEM DESCRIPTION

1. DESCRIPTION OF OCCUPANT CLASSIFICATION SYSTEM

(a) GENERAL DESCRIPTION

(1) In the occupant classification system, the occupant classification ECU calculates

the weight of the ...

Problem Symptoms Table

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are lis ...

Other materials about Toyota Venza:

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the LH side and RH side.

The following procedure is for the LH side.

PROCEDURE

1. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE (for 2GR-FE)

HINT:

Refer to the procedure up to Re ...

Registered Device cannot be Deleted

PROCEDURE

1.

DELETE OPERATION

(a) Check if a registered portable player can be deleted normally.

OK:

Registered portable player can be deleted normally.

OK

END

NG

PROCEED TO ...

Air Conditioning Amplifier

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL AIR CONDITIONING AMPLIFIER ASSEMBLY

(a) Install the air conditioning amplifier assembly with the 2 screws.

...

0.1284