Toyota Venza: Indicator Circuit

DESCRIPTION

The headlight beam level control system indicator light in the combination meter assembly comes on for approximately 3 seconds when the ignition switch is turned to ON. The indicator light also comes on when the headlight leveling ECU assembly detects a malfunction.

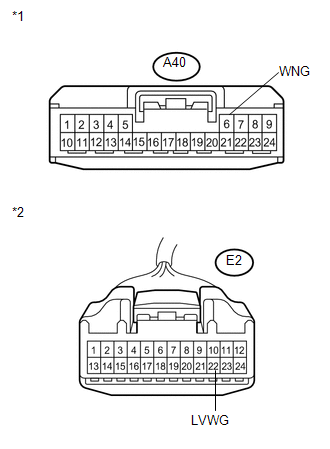

WIRING DIAGRAM

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (BATTERY - COMBINATION METER ASSEMBLY) |

|

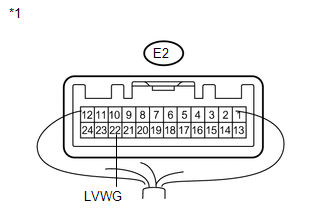

(a) Disconnect the E2 combination meter assembly connector. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

E2-13 (IG+) - Body ground |

Ignition switch ON |

11 to 14 V |

|

Ignition switch off |

Below 1 V |

|

*1 |

Front view of wire harness connector (to Combination Meter Assembly) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

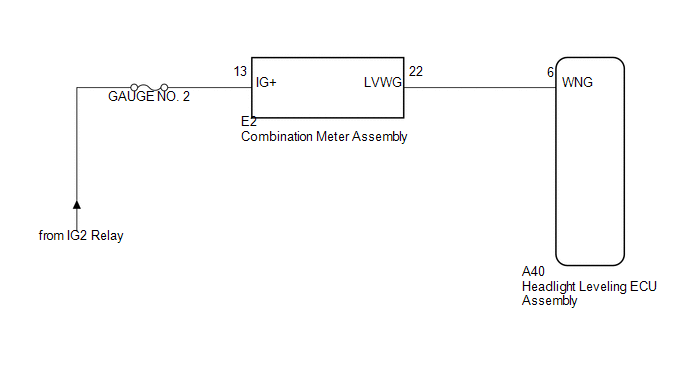

2. |

CHECK HARNESS AND CONNECTOR (COMBINATION METER ASSEMBLY - HEADLIGHT LEVELING ECU ASSEMBLY) |

|

(a) Disconnect the A40 headlight leveling ECU assembly connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A40-6 (WNG) - E2-22 (LVWG) |

Always |

Below 1 Ω |

|

A40-6 (WNG) - Body ground |

Always |

10 kΩ or higher |

|

*1 |

Front view of wire harness connector (to Headlight Leveling ECU Assembly) |

|

*2 |

Front view of wire harness connector (to Combination Meter Assembly) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

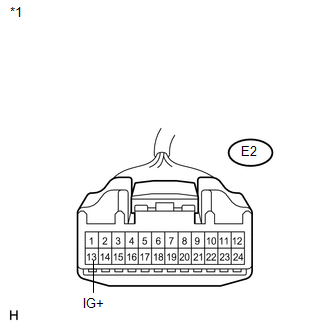

3. |

INSPECT COMBINATION METER ASSEMBLY |

|

(a) Reconnect the E2 combination meter assembly connector. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

E2-22 (LVWG) - Body ground |

Ignition switch ON |

11 to 14 V |

|

*1 |

Component with harness connected (Combination Meter Assembly) |

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) |

REPLACE COMBINATION METER ASSEMBLY |

Headlight Leveling ECU Power Source Circuit

Headlight Leveling ECU Power Source Circuit

DESCRIPTION

This circuit detects the state of the ignition switch, and sends it to the headlight

leveling ECU assembly.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for ci ...

Speed Signal Circuit

Speed Signal Circuit

DESCRIPTION

The headlight leveling ECU assembly receives the vehicle speed signal from the

combination meter assembly.

HINT:

A voltage of 12 V or 5 V is output from each ECU and then inpu ...

Other materials about Toyota Venza:

Throttle / Pedal Position Sensor / Switch "D" Circuit Range / Performance (P2121)

DESCRIPTION

Refer to DTC P2120 (See page ).

HINT:

This DTC relates to the accelerator pedal sensor assembly.

DTC No.

DTC Detection Condition

Trouble Area

P2121

Either of following conditions 1 o ...

Lost Communication with ECM / PCM "A" (U0100-U0142,U0155)

DESCRIPTION

These DTCs are stored when the clearance warning ECU assembly cannot receive

and recognize several signals via the CAN communication system.

DTC No.

DTC Detection Condition

Trouble Area

U0100

...

Steering Pad Switch Circuit

DESCRIPTION

This circuit sends an operation signal from the steering pad switch assembly

to the radio and display receiver assembly.

If there is an open in the circuit, the audio system cannot be operated using

the steering pad switch assembly.

If there ...

0.1582

.gif)