Toyota Venza: IG Power Supply Voltage Malfunction (C1551)

DESCRIPTION

The power steering ECU distinguishes the ignition switch status as ON or off through the IG power source circuit.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

C1551 |

IG power source circuit malfunction inside ECU |

|

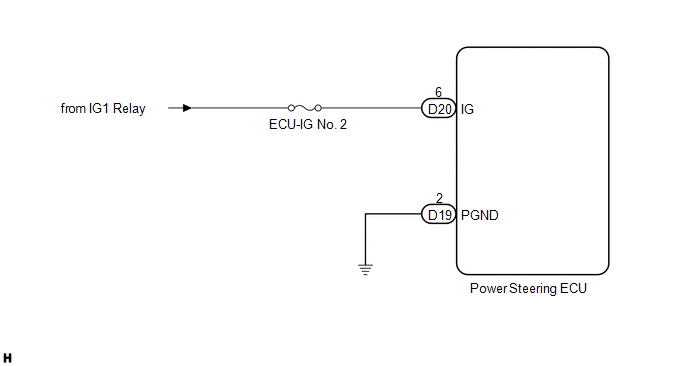

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- If the power steering ECU has been replaced with a new one, perform

the rotation angle sensor initialization and torque sensor zero point calibration

(See page

.gif) ).

). - Inspection the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

READ VALUE USING TECHSTREAM (IG POWER SUPPLY) |

(a) Turn the ignition switch off.

(b) Connect the Techstream to the DLC3.

(c) Turn the ignition switch to ON.

(d) Turn the Techstream on.

(e) Enter the following menus: Chassis / EMPS / Data List.

(f) Select the items "IG Power Supply" in the Data List and read the value displayed on the Techstream.

EMPS|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

IG Power Supply |

ECU power source voltage/ Min.: 0 V Max.: 20.1531 V |

11 to 14 V |

Ignition switch ON |

OK:

Normal condition value is displayed the Techstream.

| OK | .gif) |

REPLACE POWER STEERING ECU |

|

|

2. |

CHECK HARNESS AND CONNECTOR (BATTERY - POWER STEERING ECU) |

|

(a) Disconnect the connectors from the power steering ECU. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

D20-6 (IG) - Body ground |

Ignition switch ON |

11 to 14 V |

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D19-2 (PGND) - Body ground |

Always |

Below 1 Ω |

|

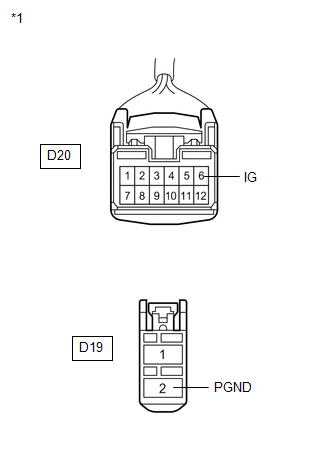

*1 |

Front view of wire harness connector (to Power Steering ECU) |

| OK | .gif) |

REPLACE POWER STEERING ECU |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Assist Map Number Un-Writing (C1581)

Assist Map Number Un-Writing (C1581)

DESCRIPTION

The power steering ECU stores this DTC when it determines that the assist map

is not written in the ECU.

HINT:

The assist map is data written in the power steering ECU to control the ...

Motor Rotation Angle Sensor Malfunction (C1528)

Motor Rotation Angle Sensor Malfunction (C1528)

DESCRIPTION

The motor rotation angle sensor detects the motor rotation angle and sends this

information to the power steering ECU.

DTC No.

DTC Detection Condition

...

Other materials about Toyota Venza:

Brake Pedal Load Sensing Switch (C1267/67)

DESCRIPTION

The brake pedal load sensing switch is turned on when the brake pedal is depressed

with force exceeding a predetermined level.

The skid control ECU detects if the brake pedal is depressed or not via this

circuit.

DTC Code

...

Data Signal Circuit between Navigation Receiver Assembly and Extension Module

DESCRIPTION

The stereo component tuner assembly sends the image data signal to the navigation

receiver assembly via this circuit.

WIRING DIAGRAM

PROCEDURE

1.

CHECK NAVIGATION WIRE

(a) Remove the navigation wire (See pag ...

Sound Signal Circuit between Navigation Receiver Assembly and Stereo Component

Amplifier

DESCRIPTION

The navigation receiver assembly sends a sound signal to the stereo component

amplifier assembly via this circuit.

The sound signal that has been sent is amplified by the stereo component amplifier

assembly, and then is sent to the speakers.

...

0.1202

.gif)