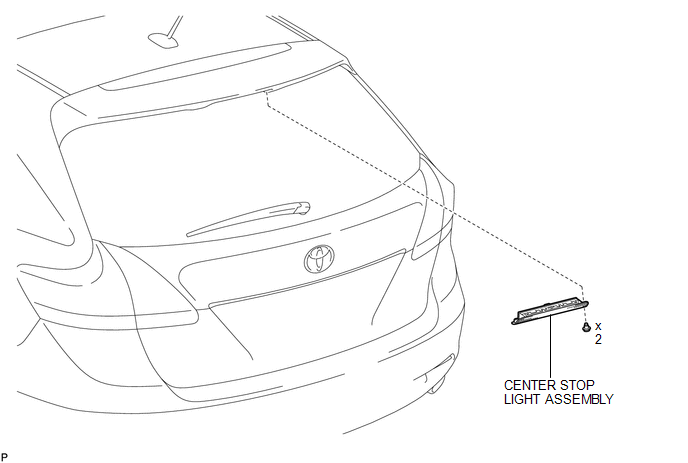

Toyota Venza: High Mounted Stop Light Assembly

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

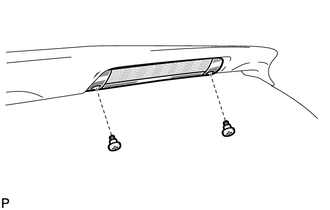

1. REMOVE CENTER STOP LIGHT ASSEMBLY

|

(a) Using a short screwdriver, remove the 2 screws. |

|

(b) Disconnect the connector and remove the center stop light assembly.

Inspection

INSPECTION

PROCEDURE

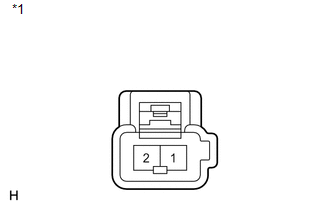

1. INSPECT CENTER STOP LIGHT ASSEMBLY

|

(a) Connect a positive (+) lead from the battery to terminal 2 and a negative (-) lead to terminal 1. |

|

(b) Check that the light comes on.

OK:

The light comes on.

Text in Illustration|

*1 |

Component without harness connected (Center Stop Light Assembly) |

If the result is not as specified, replace the center stop light assembly.

Installation

INSTALLATION

PROCEDURE

1. INSTALL CENTER STOP LIGHT ASSEMBLY

(a) Connect the connector.

|

(b) Using a short screwdriver, install the center stop light assembly with the 2 screws. |

|

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

PROCEDURE

1. PRECAUTION

NOTICE:

After turning the ignition switch off, waiting time may be required before disconnecting

the cable from the negative (-) battery ...

License Plate Light Assembly

License Plate Light Assembly

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL LICENSE PLATE LIGHT ASSEMBLY

(a) Engage the 2 claws to install the license pla ...

Other materials about Toyota Venza:

Using a flat bed truck

If you use chains or cables to tie down your vehicle, the angles shaded in black

must be 45°.

Do not overly tighten the tie downs or the vehicle may be damaged.

NOTICE

- To prevent body damage when towing a sling-type truck

Do not tow with a sli ...

Console Box Light

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE UPPER CONSOLE PANEL SUB-ASSEMBLY (w/o Seat Heater System)

2. REMOVE UPPER CONSOLE PANEL SUB-ASSEMBLY (w/ Seat Heater System)

3. REMOVE NO. 2 CONSOLE BOX CARPET

4. RE ...

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful bec ...

0.1734

.png)