Toyota Venza: Front Brake Flexible Hose

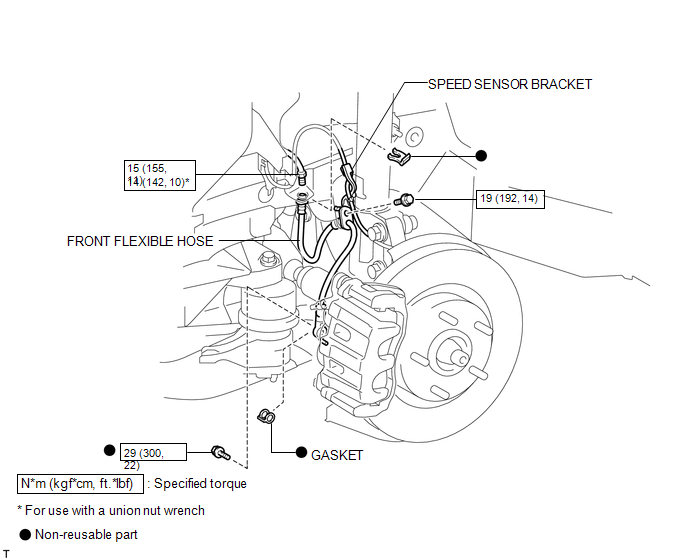

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

- Because the left and right hoses are not interchangeable, verify the part number when installing the flexible hoses.

- If the hoses are to be reused, connect them after checking the identification marks placed when each hose was disconnected.

PROCEDURE

1. INSTALL FRONT FLEXIBLE HOSE

|

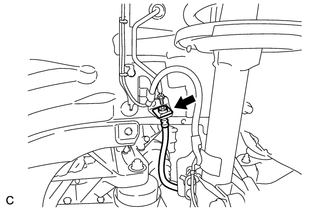

(a) Connect the front flexible hose to the disc brake cylinder assembly with a new union bolt and a new gasket. Torque: 29 N·m {300 kgf·cm, 22 ft·lbf} HINT: Install the front flexible hose lock securely into the lock hole in the front disc brake cylinder assembly. |

|

|

(b) Install the front flexible hose with a new clip. NOTICE: Install the clip as far as it will go. |

|

|

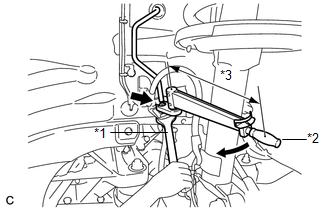

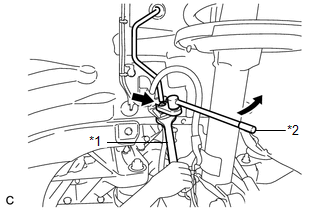

(c) Using a union nut wrench, connect the brake line to the front flexible hose while holding the front flexible hose with a wrench. Text in Illustration

Torque: Specified Tightening Torque : 15 N·m {155 kgf·cm, 11 ft·lbf} NOTICE:

HINT:

|

|

|

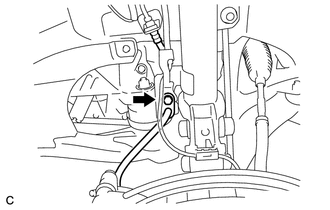

(d) Install the front flexible hose together with the speed sensor bracket to the absorber bracket with the bolt. Torque: 19 N·m {192 kgf·cm, 14 ft·lbf} NOTICE: First install the speed sensor harness bracket, and then install the flexible hose bracket. |

|

2. FILL RESERVOIR WITH BRAKE FLUID

.gif)

3. BLEED BRAKE LINE

.gif)

4. INSPECT FOR BRAKE FLUID LEAK

5. INSPECT FLUID LEVEL IN RESERVOIR

.gif)

6. INSTALL FRONT WHEEL

Torque:

103 N·m {1050 kgf·cm, 76 ft·lbf}

Removal

REMOVAL

CAUTION / NOTICE / HINT

NOTICE:

If both the left and right side hoses are removed at the same time, be sure to place identification marks indicating the position on each side.

HINT:

- Use the same procedure for the LH side and RH side.

- The following procedure listed is for the LH side.

PROCEDURE

1. REMOVE FRONT WHEEL

2. DRAIN BRAKE FLUID

NOTICE:

If brake fluid leaks onto any painted surface, immediately wash it off.

3. REMOVE FRONT FLEXIBLE HOSE

|

(a) Remove the union bolt and gasket, and separate the front flexible hose. |

|

|

(b) Using a union nut wrench, disconnect the brake line from the front flexible hose while holding the front flexible hose with a wrench. Text in Illustration

NOTICE:

|

|

|

(c) Remove the clip. |

|

|

(d) Remove the bolt and front flexible hose from the absorber bracket. |

|

Installation

Installation

INSTALLATION

PROCEDURE

1. TEMPORARILY TIGHTEN FRONT DISC BRAKE BLEEDER PLUG

(a) Temporarily tighten the front disc brake bleeder plug.

HINT:

Fully tighten the front disc brake bleeder plug after ...

Brake (rear)

Brake (rear)

...

Other materials about Toyota Venza:

Pcv Valve

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE INTAKE MANIFOLD

(a) Remove the intake manifold (See page ).

2. REMOVE VENTILATION VALVE SUB-ASSEMBLY

(a) Disconnect the No. 2 ventilation hose from the ventilatio ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL DISCHARGE HEADLIGHT BULB

HINT:

Use the same procedure for the RH side and LH side (See page

).

2. INSTALL LIGHT CONTROL ECU (for LH Side)

(a) Turn the socket of the light control ECU in the direction indicat ...

Door Unlock Detection Switch Circuit

DESCRIPTION

The main body ECU (driver side junction block assembly) detects the condition

of the door unlock detection switch.

WIRING DIAGRAM

PROCEDURE

1.

READ VALUE USING TECHSTREAM

(a) Connect the Techstream to the DL ...

0.1728

.png)

.png)

.png)

.png)