Toyota Venza: Brake

General Maintenance

GENERAL MAINTENANCE

PROCEDURE

1. INSPECT BRAKE LINE PIPES AND HOSES

HINT:

Work in a well-lighted area. Turn the front wheels fully to the right or left before beginning the inspection.

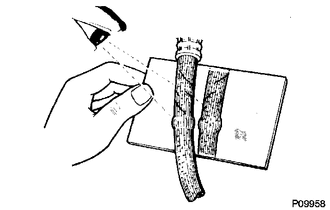

(a) Using a mirror, check the entire circumference and length of the brake lines and hoses for:

- Damage

- Wear

- Deformation

- Cracks

- Corrosion

- Leaks

- Kinks

- Twists

(b) Check all the clamps for tightness and check the connections for leaks.

(c) Check that the hoses and lines are not near sharp edges, moving parts or the exhaust system.

(d) Check that the lines are installed properly and pass through the center of the grommets.

2. INSPECT BRAKE PEDAL

(a) Check the brake pedal (See page .gif) ).

).

3. INSPECT PARKING BRAKE

(a) Check the parking brake shoe clearance and parking brake pedal travel (See

page .gif) ).

).

(b) Check the parking brake cables to ensure that they are not deformed or binding.

4. INSPECT BRAKE LININGS AND DRUMS

(a) Check the parking brake linings and drums.

5. INSPECT FRONT BRAKE

(a) Check the front brake pads and discs (See page

.gif) ).

).

6. INSPECT REAR BRAKE

(a) Check the rear brake pads and discs (See page

.gif) ).

).

7. INSPECT OR CHANGE BRAKE FLUID

(a) Inspect or change the brake fluid (See page

.gif) ).

).

Fluid:

SAE J1703 or FMVSS No. 116 DOT3

Body

Body

General Maintenance

GENERAL MAINTENANCE

PROCEDURE

1. TIGHTEN BOLTS AND NUTS ON CHASSIS AND BODY

(a) If necessary, tighten the bolts and nuts on the chassis parts listed below.

Front axle ...

Chassis

Chassis

General Maintenance

GENERAL MAINTENANCE

PROCEDURE

1. INSPECT STEERING LINKAGE AND GEAR HOUSING

(a) Check the steering wheel free play (See page

).

(b) Check the steering linkage for looseness ...

Other materials about Toyota Venza:

Replacing a flat tire

Chock the tires.

Slightly loosen the wheel nuts (one turn).

Turn the tire jack portion “A” by hand until the notch of the jack is in contact

with the jack point.

Raise the vehicle until the tire is slightly raised off the ground.

Remove a ...

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the cable from the negative (-)

battery terminal to disable the SRS system (See page

).

NOTICE:

When disconnecting the cable, s ...

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

Use the following procedure to troubleshoot the lighting system.

*: Use the Techstream.

PROCEDURE

1.

VEHICLE BROUGHT TO WORKSHOP

NEXT

...

0.1239