Toyota Venza: Air Fuel Ratio Sensor

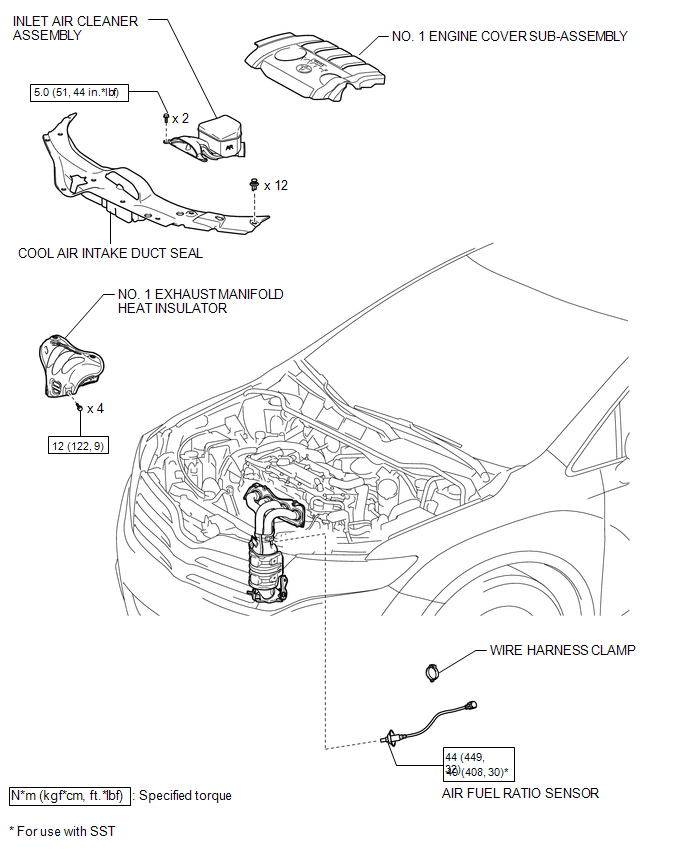

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

.gif)

2. REMOVE COOL AIR INTAKE DUCT SEAL

.gif)

3. REMOVE INLET AIR CLEANER ASSEMBLY

.gif)

4. REMOVE NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

.gif)

5. REMOVE AIR FUEL RATIO SENSOR

|

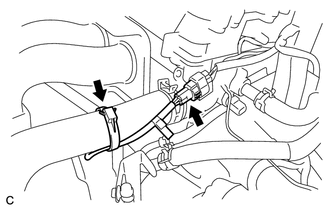

(a) Disconnect the air fuel ratio sensor connector. |

|

(b) Remove the wire harness clamp.

|

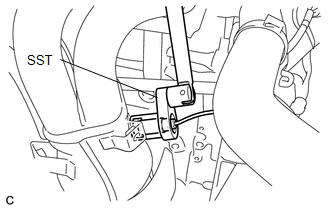

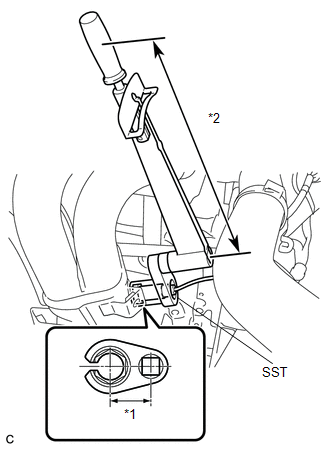

(c) Using SST, remove the air fuel ratio sensor from the exhaust manifold. SST: 09224-00011 |

|

Inspection

INSPECTION

PROCEDURE

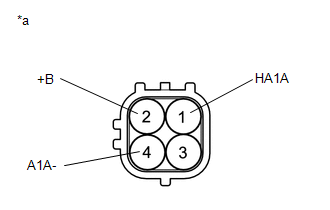

1. INSPECT AIR FUEL RATIO SENSOR (for Bank 1 Sensor 1)

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the air fuel ratio sensor. Text in Illustration

|

|

Installation

INSTALLATION

PROCEDURE

1. INSTALL AIR FUEL RATIO SENSOR

|

(a) Using SST, install the air fuel ratio sensor to the exhaust manifold. Text in Illustration

SST: 09224-00011 Torque: without SST : 44 N·m {449 kgf·cm, 32 ft·lbf} with SST : 40 N·m {408 kgf·cm, 30 ft·lbf} NOTICE:

HINT: Perform "Inspection After Repair" after replacing the air fuel ratio

sensor (See page |

|

|

(b) Connect the air fuel ratio sensor connector. |

|

(c) Install the wire harness clamp.

2. INSPECT FOR EXHAUST GAS LEAK

3. INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

.gif)

4. INSTALL INLET AIR CLEANER ASSEMBLY

.gif)

5. INSTALL COOL AIR INTAKE DUCT SEAL

.gif)

6. INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY

.gif)

Accelerator Pedal

Accelerator Pedal

Components

COMPONENTS

ILLUSTRATION

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT ACCELERATOR PEDAL SENSOR ASSEMBLY

(a) Connect the Techstream to the DLC3.

(b) Turn the ...

Other materials about Toyota Venza:

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

Use the following procedure to troubleshoot the audio and visual system.

*: Use the Techstream.

PROCEDURE

1.

VEHICLE BROUGHT TO WORKSHOP

NEXT

...

Relay

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT RR DEF RELAY

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection

Condition

...

Transfer Case Rear Oil Seal

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

Replacement

REPLACEMENT

PROCEDURE

1. REMOVE TAIL EXHAUST PIPE ASSEMBLY

2. REMOVE CENTER EXHAUST PIPE ASSEMBLY

3. REMOVE PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

4. REMOVE TRANSFER C ...

0.1191

.png)