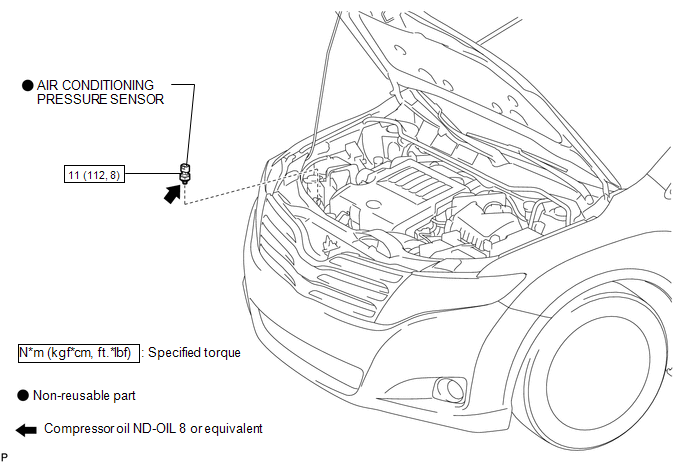

Toyota Venza: Air Conditioning Pressure Sensor

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

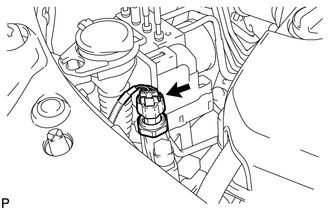

1. INSTALL AIR CONDITIONING PRESSURE SENSOR

|

(a) Sufficiently apply compressor oil to a new air conditioning pressure sensor. Compressor oil: ND-OIL 8 or equivalent |

|

(b) Install the air conditioning pressure sensor.

Torque:

11 N·m {112 kgf·cm, 8 ft·lbf}

(c) Connect the connector.

2. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

3. CHARGE WITH REFRIGERANT

.gif)

4. WARM UP ENGINE

.gif)

5. INSPECT FOR REFRIGERANT LEAK

.gif)

Removal

REMOVAL

PROCEDURE

1. RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM

.gif)

2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

3. REMOVE AIR CONDITIONING PRESSURE SENSOR

|

(a) Disconnect the connector. |

|

(b) Remove the air conditioning pressure sensor.

Air Conditioning Panel

Air Conditioning Panel

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL AIR CONDITIONING CONTROL ASSEMBLY

(a) Connect the connector.

(b) Engage the 2 clips and 4 gui ...

Other materials about Toyota Venza:

Installation

INSTALLATION

PROCEDURE

1. INSTALL NO. 1 COOLER THERMISTOR

2. INSTALL COOLER EVAPORATOR SUB-ASSEMBLY

3. INSTALL BLOWER ASSEMBLY WITH COOLER EVAPORATOR SUB-ASSEMBLY

(a) Engage the 5 claws.

(b) Engage the guide and connect the wire harness.

(c) Insta ...

Cold Start Ignition Timing Performance (P050B)

DESCRIPTION

This monitor will run when the engine is started at an engine coolant temperature

of -10 to 50°C (14 to 122°F). The DTC is stored after the engine idles for 13

seconds (2 trip detection logic).

The DTC is designed to monitor the ignition ti ...

Parking Brake Switch Circuit

DESCRIPTION

This circuit is from the parking brake switch assembly to the radio and display

receiver assembly.

WIRING DIAGRAM

PROCEDURE

1.

CHECK BRAKE WARNING LIGHT

(a) Check that the brake warning light comes on when t ...

0.1162

.png)