Toyota Venza: Replacement

REPLACEMENT

PROCEDURE

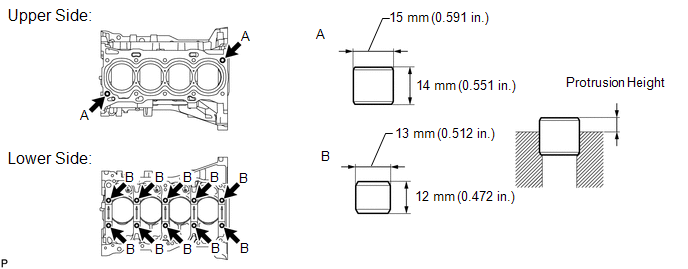

1. REPLACE RING PIN

NOTICE:

It is not necessary to remove the ring pin unless it is being replaced.

(a) Remove the 12 ring pins.

(b) Using a plastic-faced hammer, install 12 new ring pins.

Standard Protrusion Height:

|

Item |

Specified Condition |

|---|---|

|

A |

5.0 to 7.0 mm (0.197 to 0.276 in.) |

|

B |

4.0 to 7.0 mm (0.157 to 0.276 in.) |

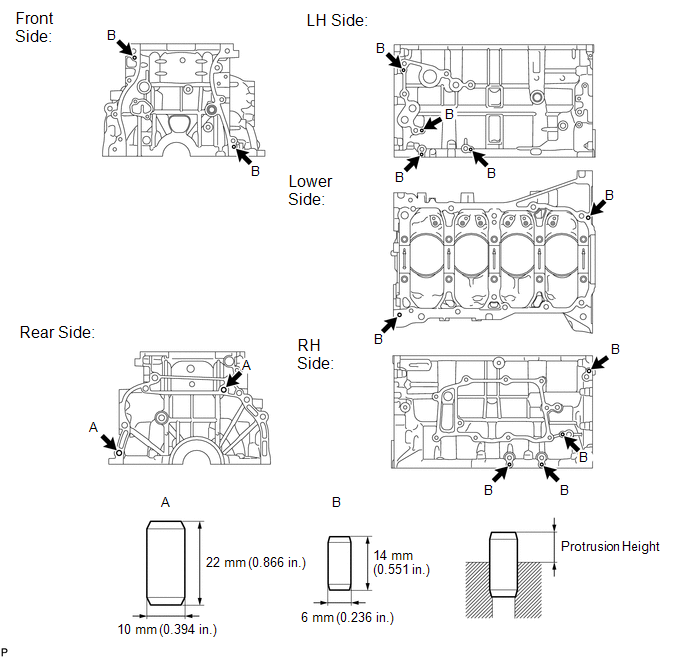

2. REPLACE STRAIGHT PIN

NOTICE:

It is not necessary to remove the straight pin unless it is being replaced.

(a) Remove the 14 straight pins.

(b) Using a plastic-faced hammer, install 14 new straight pins.

Standard Protrusion Height:

|

Item |

Specified Condition |

|---|---|

|

A |

11.0 to 13.0 mm (0.433 to 0.512 in.) |

|

B |

5.0 to 7.0 mm (0.197 to 0.276 in.) |

Reassembly

Reassembly

REASSEMBLY

CAUTION / NOTICE / HINT

HINT:

Perform "Inspection After Repair" after replacing the piston or piston ring (See

page ).

PROCEDURE

1. INSTALL STUD BOLT

NOTICE:

If a stud b ...

Cylinder Head

Cylinder Head

...

Other materials about Toyota Venza:

Fog light switch

The fog lights improve visibility in difficult driving conditions, such as

in rain or fog. The fog lights can be used when the headlights are on low beam.

Type A

1. Off

2. On

Type B

1. Off

2. On

Wiper intervals can be adjusted for intermittent ...

Engine Hood Courtesy Switch Circuit

DESCRIPTION

The security courtesy switch is installed together with the hood lock. This switch

turns off when the engine hood is opened and turns on when the engine hood is closed.

WIRING DIAGRAM

PROCEDURE

1.

INSPECT HOOD LOCK AS ...

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 1 ENGINE UNDER COVER

2. REMOVE NO. 2 ENGINE UNDER COVER

3. REMOVE WINDSHIELD WIPER MOTOR AND LINK

(a) Remove the windshield wiper motor and link (See page

).

4. REMOVE OUTER COWL TOP PANEL SUB-ASSEMBLY

5. DRAIN ENGIN ...

0.1738